Power head movement friction pair for down-hole drilling machine

A technology of motion friction and down-the-hole drilling rigs, which is applied to the driving device for drilling in the wellbore, drilling equipment, earthwork drilling and production, etc. It can solve the problems of fast wear of the guide rail, low service life of the guide rail, and large sliding contact surface. Reduce the wear of the guide rail, prolong the service life, the effect of small contact surface and running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

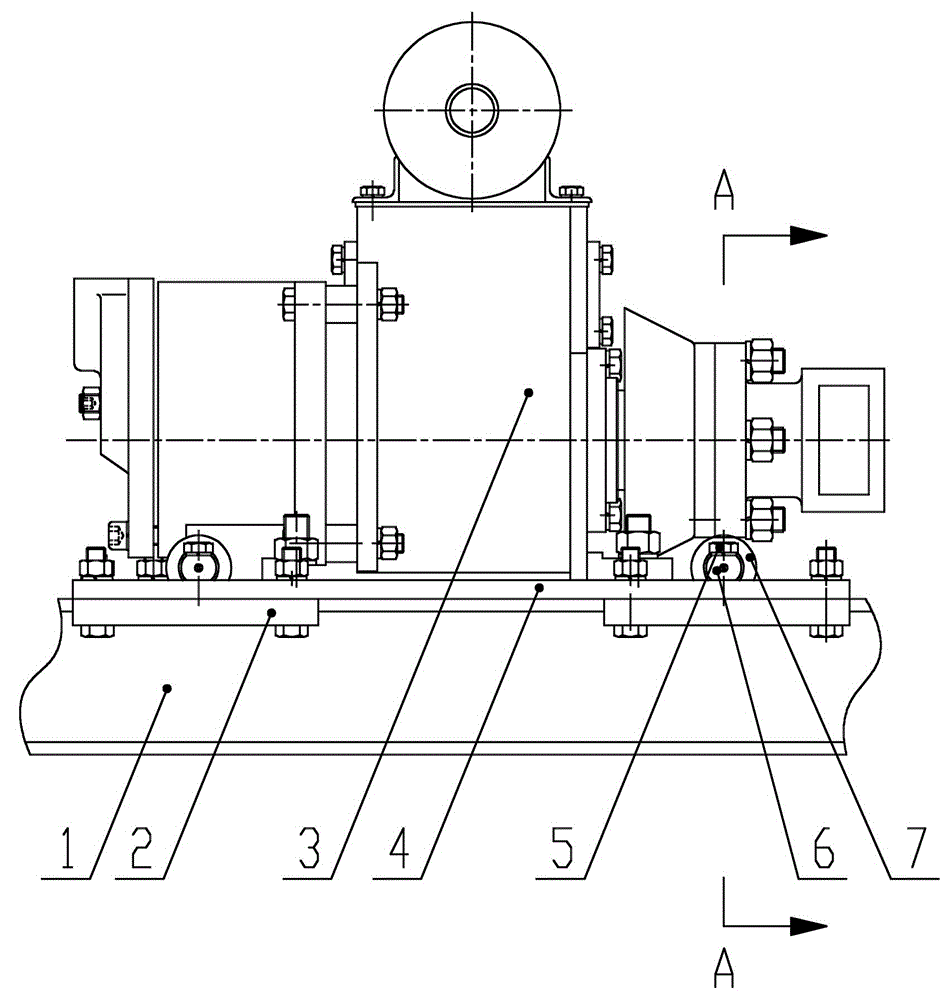

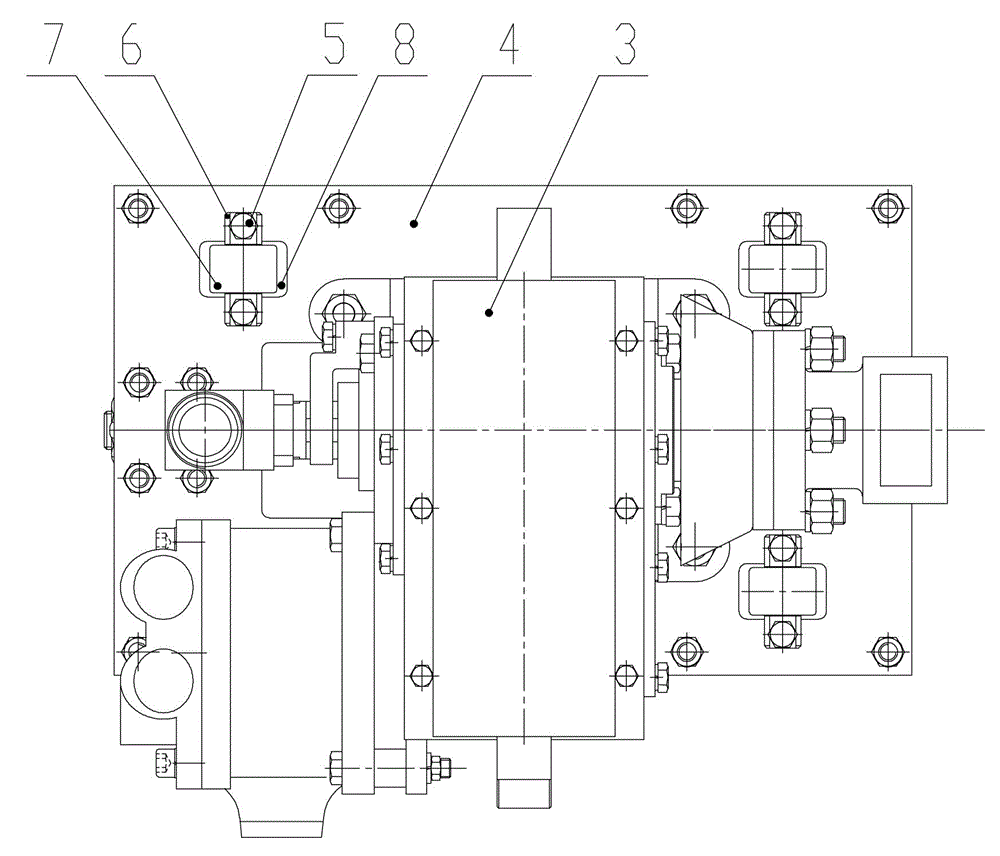

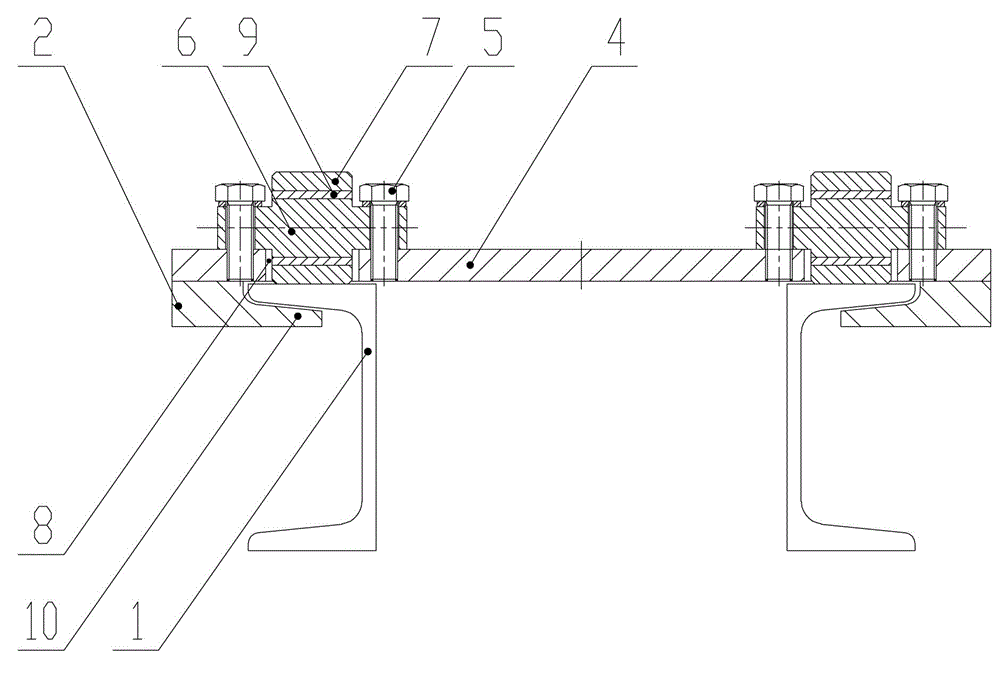

[0011] see figure 1 , figure 2 with image 3 , the present invention includes a guide rail 1, on which a power head mount is slidably installed, and the power head mount has a connecting plate 4 that is slidably mounted on the top of the guide rail 1, and the top of the connecting plate 4 is fixedly equipped with a power head 3 and a connecting plate 4 Two pairs of guide plates 2 are installed on the left and right sides of the bottom, and the bottom of each guide plate 2 is provided with a hook plate 10 protruding from the guide rail 1. The hook plate 10 buckles the guide rail 1 and cooperates with the guide rail 1; especially: Two pairs of roller mounting holes 8 are arranged on the connecting plate 4 directly above the two guide rails 1, and a rotatable roller 7 is installed in each roller mounting hole 8, and the bottom of the rollers 7 is lower than the bottom of the connecting plate 4 and connected to the bottom of the connecting plate 4. Rail 1 rolling connection.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com