Conveniently detached assembling flat plate type metal guard bar

A flat, metal technology, used in fences, road safety devices, bridge parts, etc., can solve the problems of inability to disassemble the barrier, complicated installation process, time-consuming and laborious, etc., to achieve disassembly, replacement and maintenance, firm structure, and simplified installation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Attached below Figure 1-5 The specific embodiment of the present invention is described in further detail:

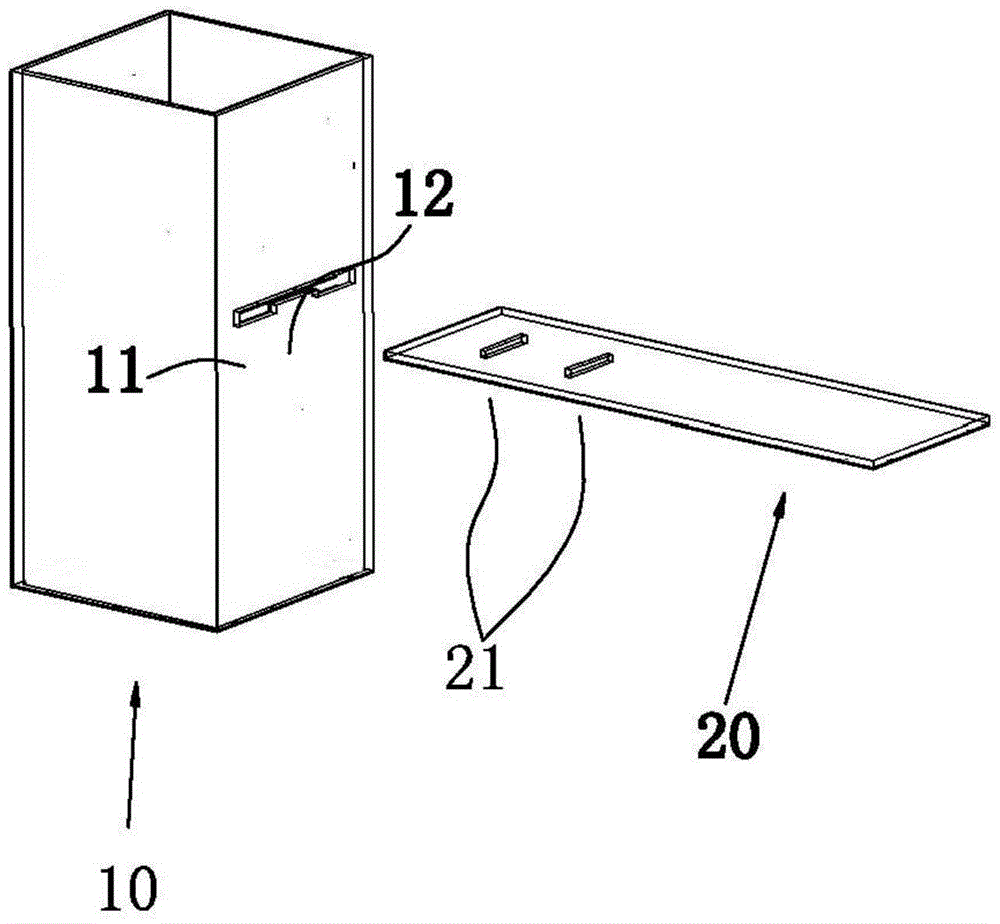

[0025] An assembled flat metal guardrail that is easy to assemble and disassemble includes: several metal columns 10 erected at intervals, and one or more metal beams 20 are connected between two adjacent metal columns 10;

[0026] The metal beam 20 is made of a horizontal plate, and a strip-shaped slot 21 is opened on the horizontal plate at the insertion end of the metal beam 20;

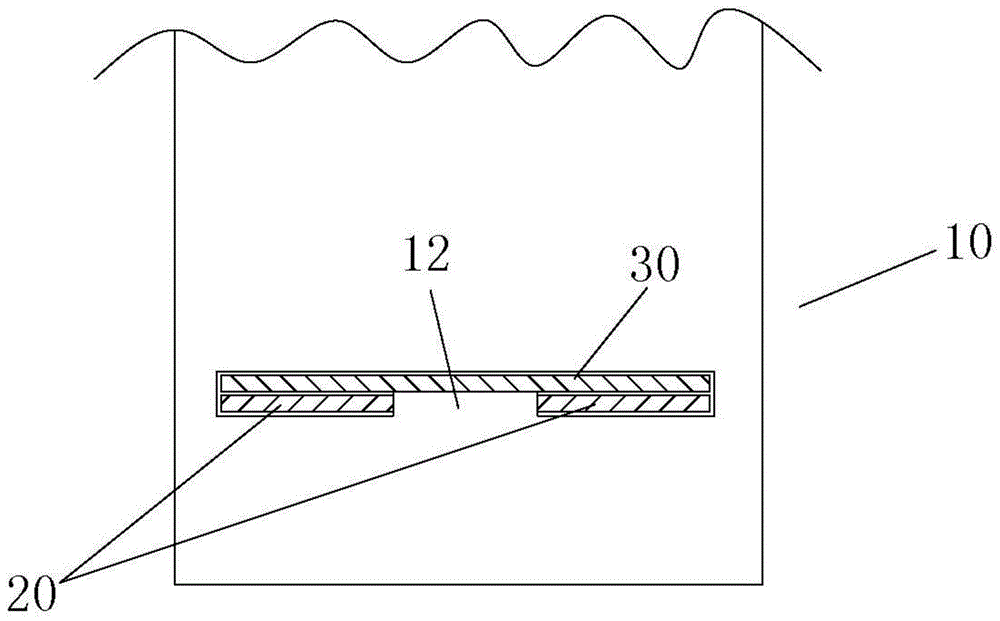

[0027] The metal column 10 is a hollow profile, and the connection surface of the metal column 10 is correspondingly provided with a plug-in card slot 11 of the same structure and size. A clip 12 is integrally formed, and the height of the clip 12 is smaller than the height of the horizontal groove 11;

[0028] During assembly, the horizontal plate at the plug-in end of the metal crossbeam 20 and the plug-in card slot 11 on the corresponding metal column 10 realize plug-in and sna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com