Four-linkage-rod workpiece controller

A controller and four-link technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of easy damage, high cost, complex structure, etc., and achieve the effect of reliable control, low cost and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

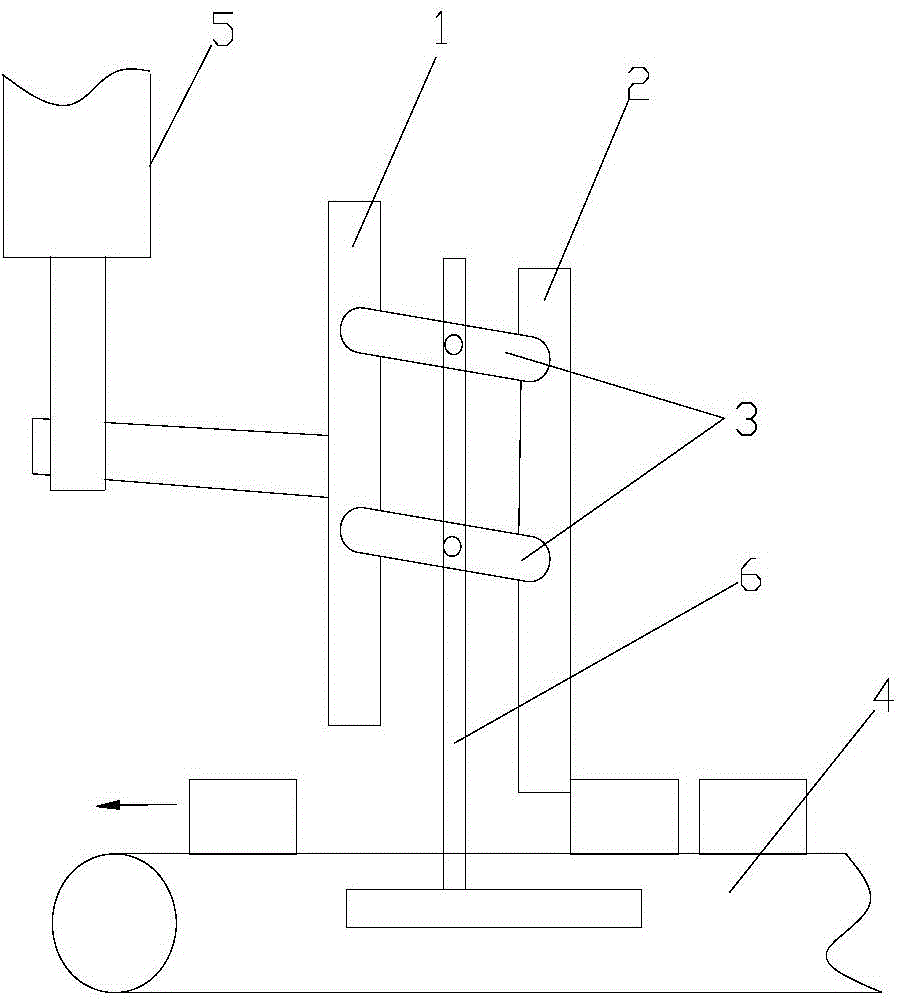

[0012] Such as figure 1 A four-link workpiece controller shown includes two connecting rods 3, a first control rod 1, a second control rod 2 and a fixed frame 6, and a strut 1.1 is set in the middle of the side of the first control rod 1, and a strut 1.1 It has an integrated structure with the first control rod 1, and has good mechanical strength and good mechanical properties. The front end of the strut 1.1 is movably connected with the front end of the piston rod of the cylinder 5, and the two connecting rods 3 are vertically opposite to each other. Between the first control rod 1 and the second control rod 2, the two ends of the connecting rod 3 are movably connected with the shafts of the first control rod 1 and the second control rod 2 respectively, so as to facilitate smooth linkage, and the middle part of the connecting rod 3 Both are movably connected on the fixed mount 6 and the fixed mount 6 is then fixed on the transmission mechanism 4 .

[0013] The present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com