Eccentric gear type torsional vibration exciter and eccentric gear type torsional vibration excitation system

A technology of eccentric gear and exciter, which is applied in the field of eccentric gear torsional vibration exciter and eccentric gear torsional vibration excitation system, which can solve the problem of long cycle, affecting the development process of the whole vehicle project, and unable to reflect the state of torsional vibration and other issues to achieve the effect of detecting fatigue durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The core of the present invention is to provide an eccentric gear type torsional vibration exciter and an eccentric gear type torsional vibration excitation system to conduct torsional vibration performance, durability and reliability simulation tests on rotating workpieces under high-speed rotation.

[0037] Hereinafter, an embodiment will be described with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solutions of the invention described in the claims.

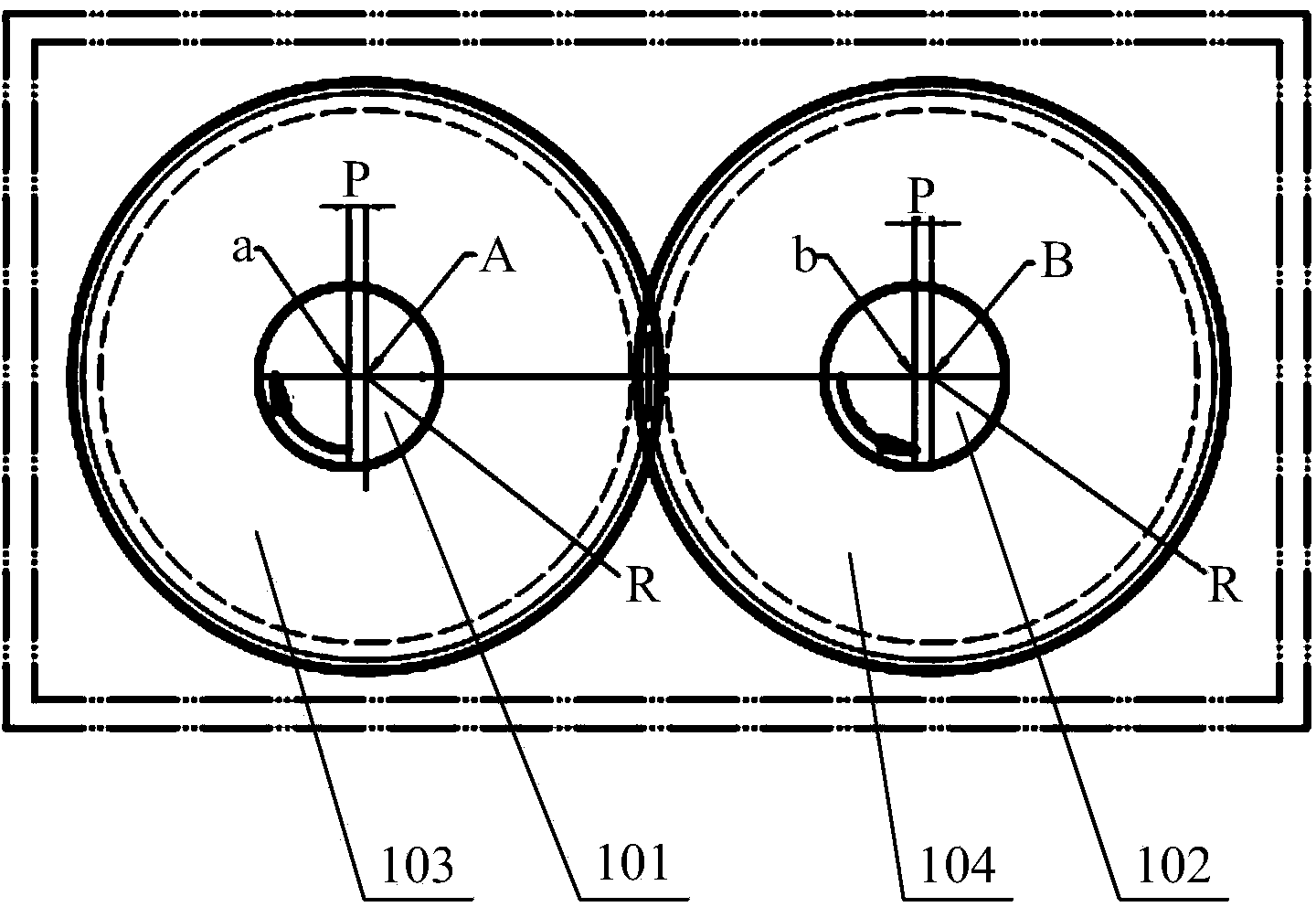

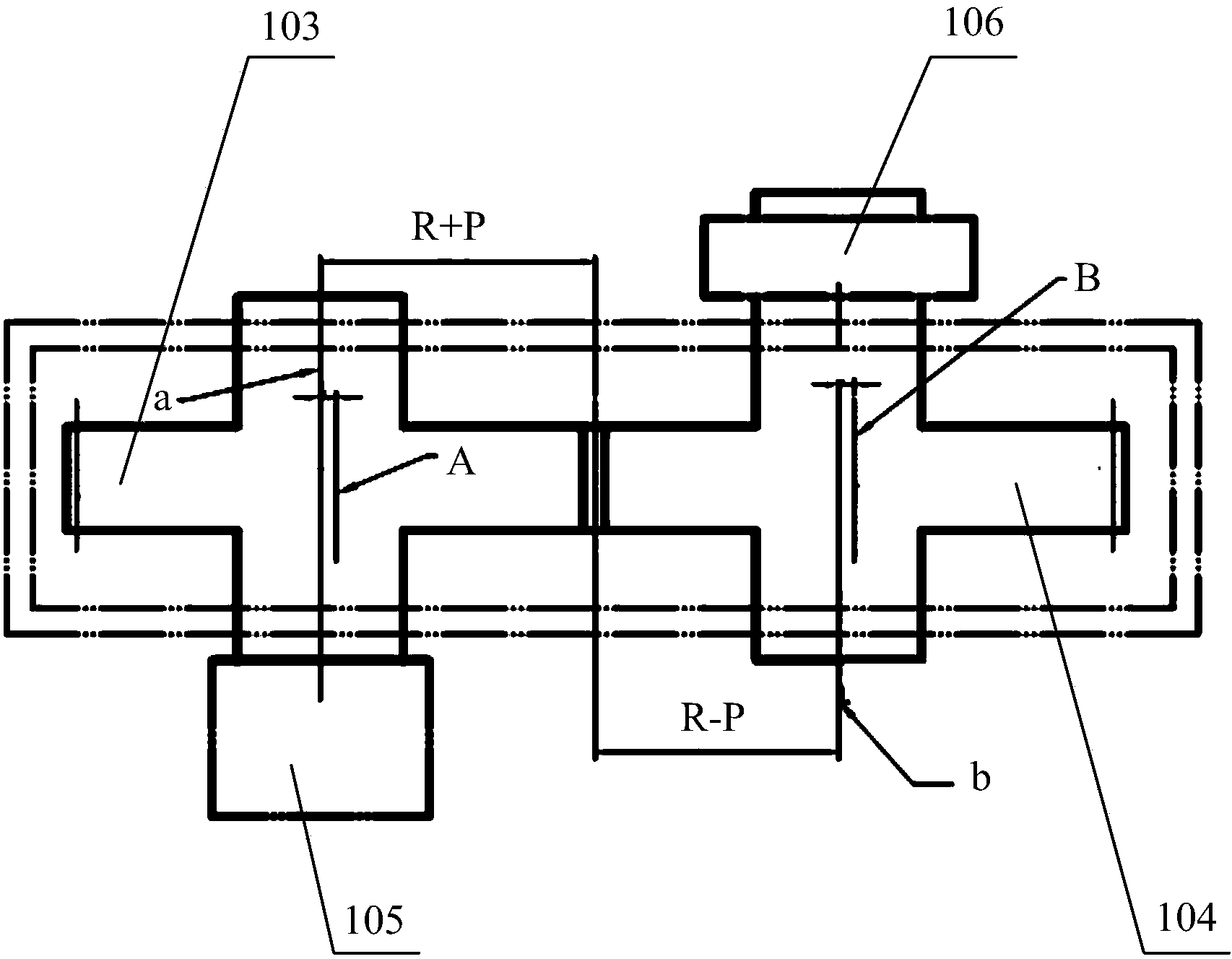

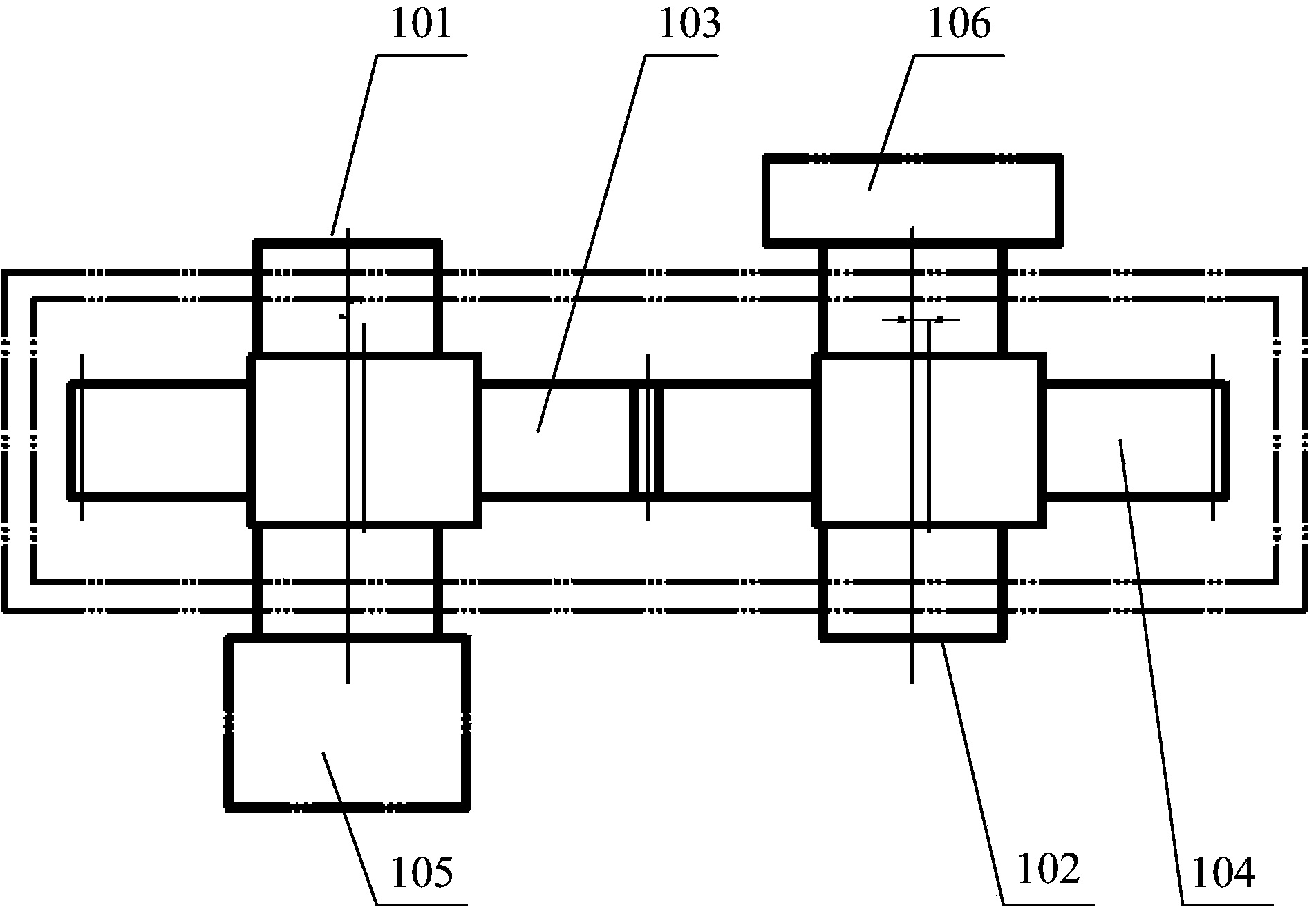

[0038] see Figure 1-Figure 3 , figure 1 Schematic diagram of the structure of the eccentric gear type torsional vibration exciter provided by the embodiment of the present invention; figure 2 A top view of the eccentric gear type torsional vibration exciter provided by Embodiment 1 of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com