Subsequent docking process of jack-up platform spud shoes

A self-elevating platform and pile shoe technology, applied in the field of ships, can solve problems such as easy collapse, and achieve the effects of fast construction speed, good quality and good construction stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

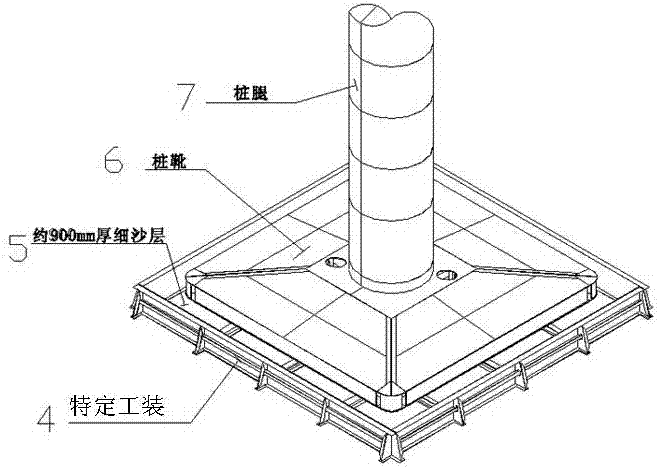

[0023] Taking the post-docking process of the jack-up platform spud shoe on a 90-meter offshore platform as an example, the following steps are included:

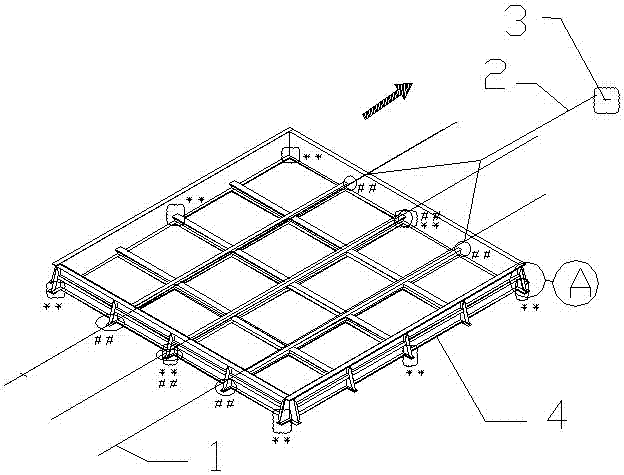

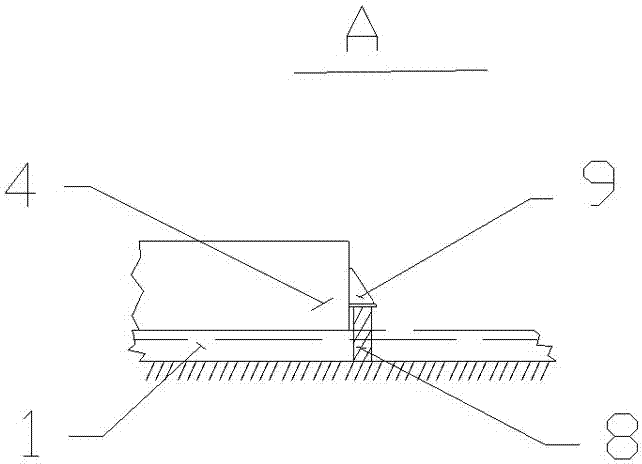

[0024] A. Tooling production and installation in place: First, it is necessary to determine the end position of the spud shoe in the dock and the entry path of the spud shoe. At the same time, the entry method needs to be considered. This plan considers the use of three rails 1 plus specific tooling 4. By considering Special tooling 2, firstly install the track, and then make the special tooling. When laying the track, the butt joint area should be considered. There are no joints and track fixing devices in the projected shadow area under the main hull of the spud shoe, so that the track can be placed after the spud shoe is in place. dismantled in time;

[0025] B. Complete loading of the main hull:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com