Air duct for locomotive resistance braking device

A resistance braking and air guide technology, applied in the field of air guide, can solve the problem of excessive radiated noise of locomotives and other problems, and achieve the effect of reducing the noise index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

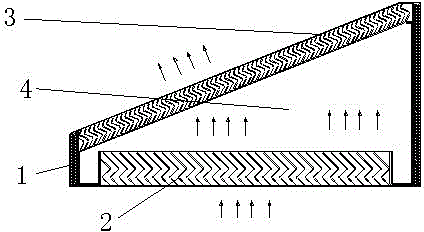

[0015] see figure 1 As shown in the figure, an air guide tube for a locomotive resistance braking device includes a cylinder body 1 with openings at both ends, an air inlet grid 2 is installed at one end of the cylinder body 1, and an air outlet grid 3 is installed at the other end. An oscillation cavity 4 is formed in the cylinder between 1 and the air outlet grid 3 . The shape and size of the vibration cavity 4 are determined according to the profile of the locomotive and the frequency of noise.

[0016] In order to enhance the heat insulation performance, the cylinder 1 is a heat insulation cylinder.

[0017] When in use, the air guide tube is installed at the air inlet and outlet of the locomotive resistance braking device. The high-speed air flow of the resistance braking enters the shock chamber 4 from the air inlet grille 2, and the air fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com