High flatness integrated solar power integral roof and rapid integration method

A flatness, solar energy technology, applied in the field of solar power generation, can solve problems such as roof water leakage, different photovoltaic module sizes, and photovoltaic modules difficult to adapt to changes in roof area, and achieve the effect of reducing construction costs, good drainage performance, and avoiding hidden dangers of water leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

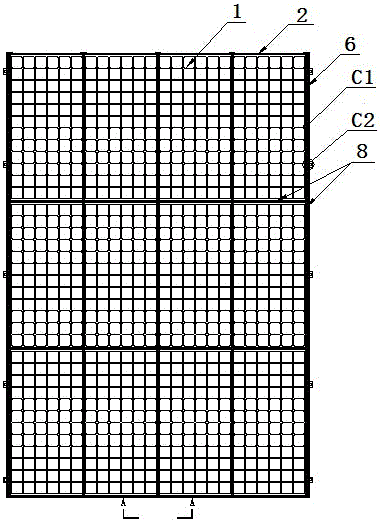

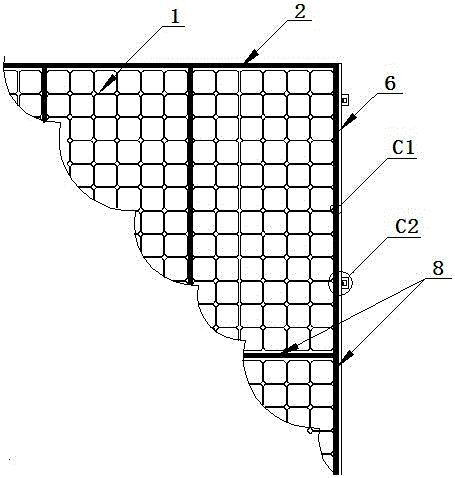

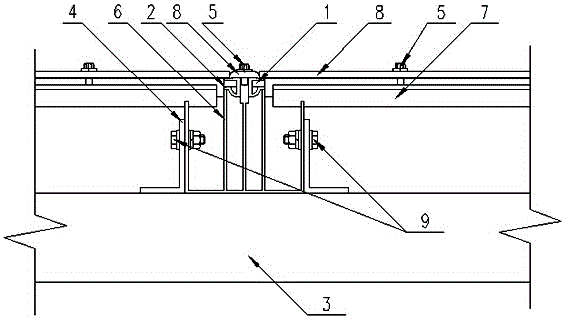

[0029] The high flatness integrated solar power generation integral roof in this embodiment consists of a frameless photovoltaic module 1 and a sealing tape 2 covering the periphery of the frameless photovoltaic module to form a photovoltaic module. The upper and lower ends and the left and right sides of the photovoltaic module are A pressure bar 8 is installed, and a water tank 6 is arranged at the lower part of the connection gap of the adjacent photovoltaic modules. The water tank 6 is erected on the upper surface of the purlin 3. The water tank and the purlin are fixedly connected by the connecting corner code 4 and the bolt 9. The pressure strip on the left and right sides of the photovoltaic module is connected to the water tank 6 are fixedly connected by self-drilling and self-tapping screws 5; the top of the water tank 6 is equipped with a horizontal connecting back strip 7, and the pressure strips at the upper and lower ends of the photovoltaic module and the horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com