Automobile bumper spraying assembly line with adjustable spraying direction

An automobile bumper and adjustable technology, which is applied in the direction of the spraying device, can solve the problems of low production efficiency, high labor intensity, and the inability to automatically adjust the spraying position of the bumper, so as to achieve high production efficiency, reduce labor intensity, and improve spraying work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

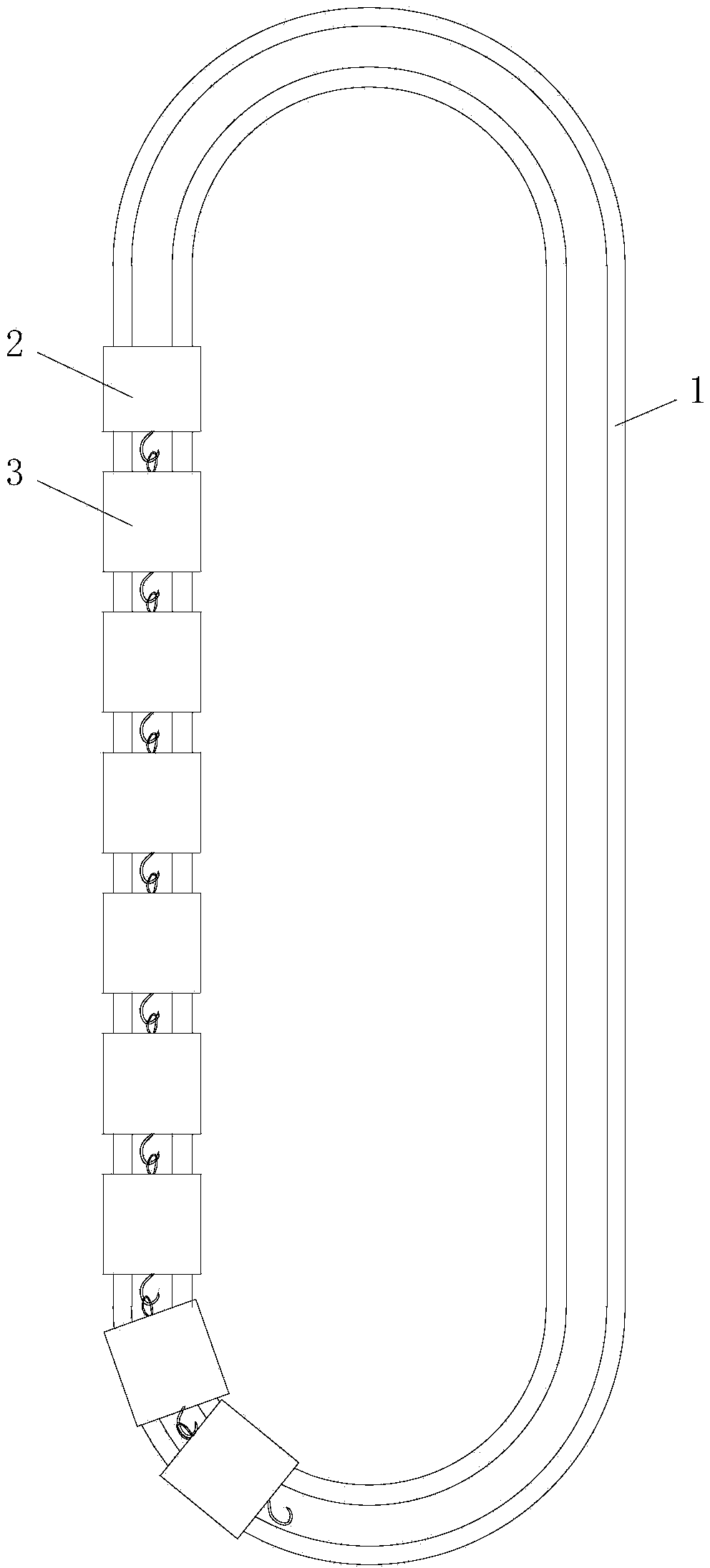

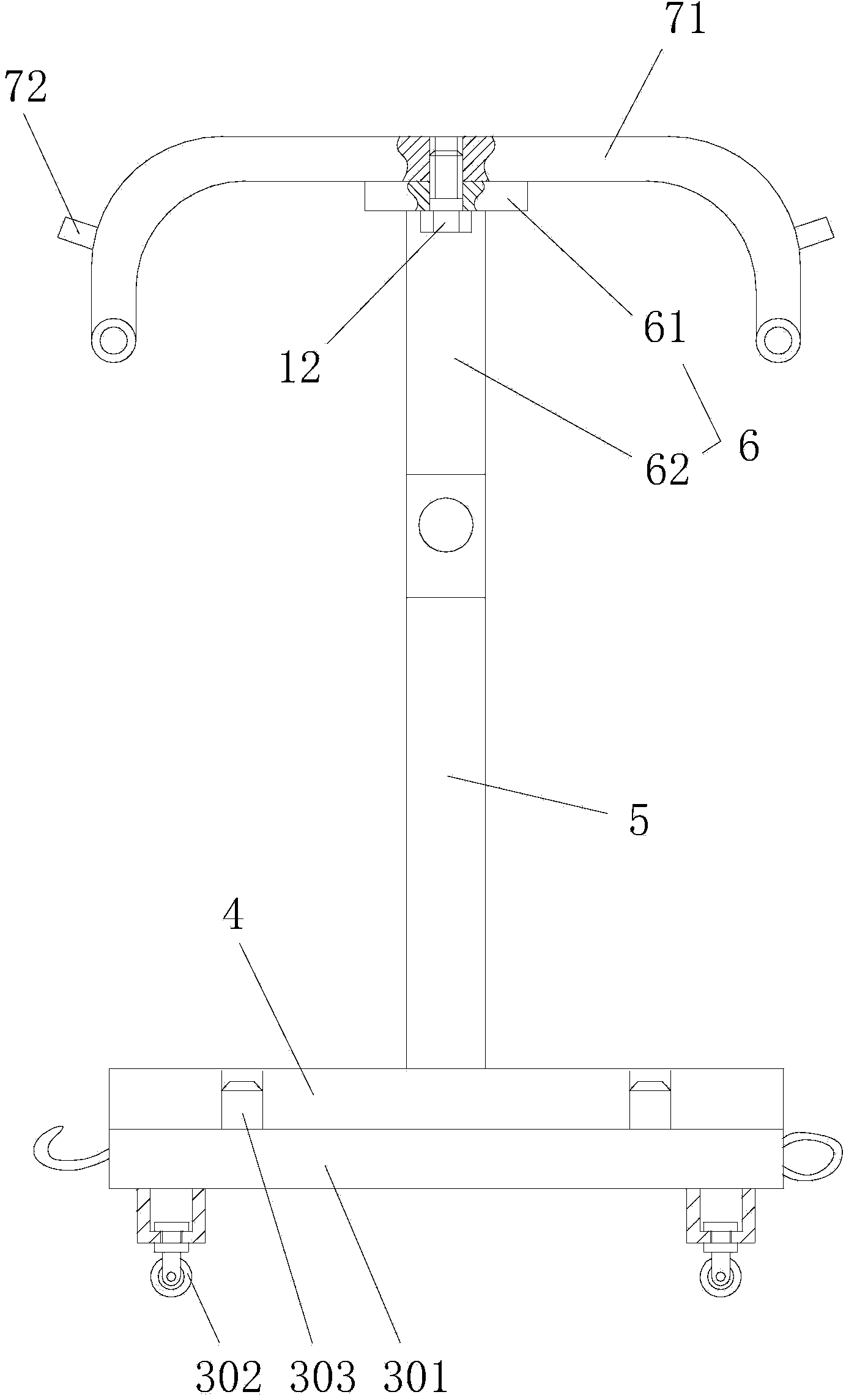

[0023] As shown in the figure, the automotive bumper spraying line with adjustable spraying orientation in this embodiment includes a bumper swing tooling and a track conveying line. The track conveying line includes an elliptical circular track 1 and a rail car arranged on the circular track. The rail car includes a locomotive 2 and a number of detachably connected tooling vehicles 3 in turn, and the tooling vehicle includes a vehicle plate 301 and a universal wheel 302 arranged below the vehicle plate;

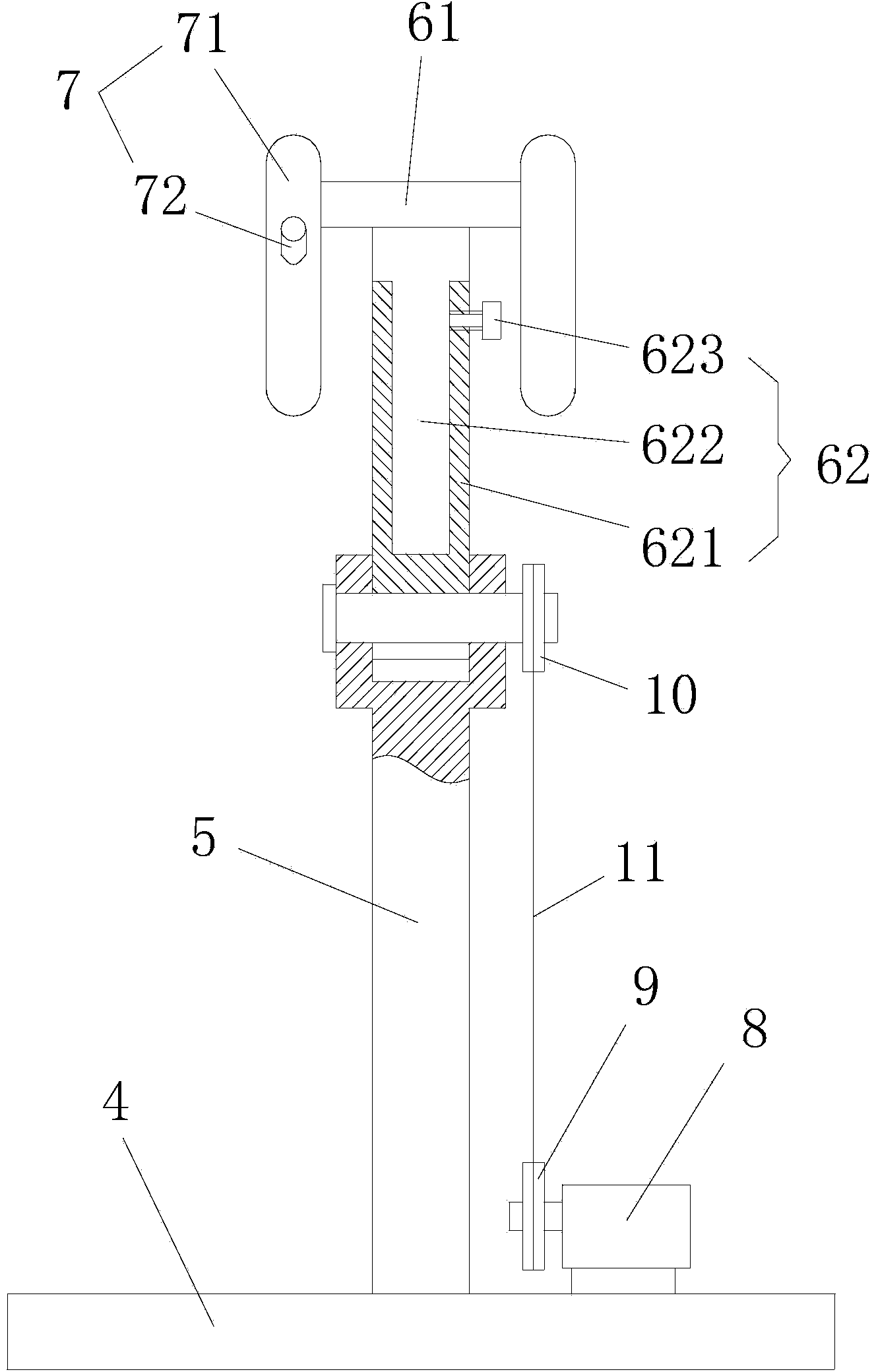

[0024] The bumper swing tooling includes a base 4 fixed on the vehicle board, a vertical rod 5 vertically fixed on the base, a T-shaped bracket 6 hingedly connected with the vertical rod, and a drive for driving the T-shaped bracket 6 to rotate around the hinge axis. device, the upper end of the cross bar 61 of the T-shaped bracket is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com