Mobile pneumatic nailing special vehicle

A special vehicle and mobile technology, which is applied in the direction of impact tools, light impact tools, manufacturing tools, etc., can solve the problems of nail bending, difficulty, and labor intensity, and achieve fast nailing speed, good firmness, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

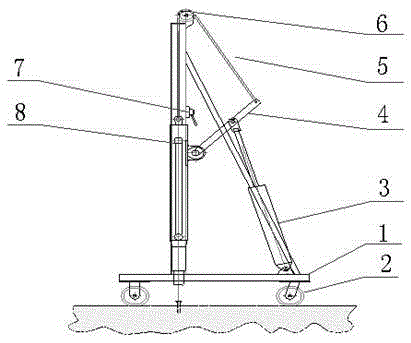

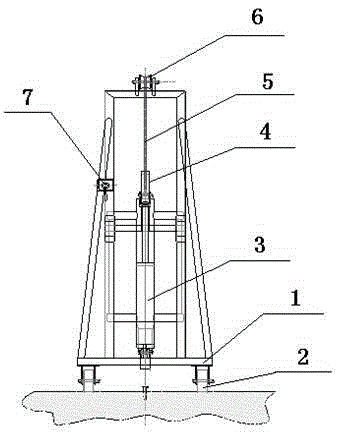

[0017] Embodiment 1: see figure 1 and figure 2 , a mobile pneumatic nailing special vehicle, comprising a vehicle body support 1, wheels, cylinder 3, rotating force arm 4, steel wire rope 5, rope passing roller 6, three-position four-way valve 7, weight channel and weight 8, The wheels are locking wheels 2, which are arranged at the lower end of the vehicle body support 1; the vehicle body support 1 is fixedly provided with a heavy hammer channel and a cylinder 3, and the heavy hammer channel passes through the vehicle body support 1 Close to the iron nail on the ground, the above-mentioned rope passing roller 6 is arranged on the top of the heavy hammer passage, and a heavy hammer 8 is arranged in the heavy hammer passage, and a steel wire rope 5 is fixedly connected to the top of the heavy hammer 8, and the steel wire rope 5 passes through the rope passing roller 6 and rotates. The free ends of the power arm 4 are fixedly connected, and the other end of the rotating power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com