Ejecting device of full-automatic axle lathe

A technology of axle lathe and jacking device, which is applied in metal processing and other directions, can solve the problems of low adaptability, high production cost, easy bending and deformation of cylinder push rod, etc., and achieve the effect of high adaptability and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the accompanying drawings and embodiments.

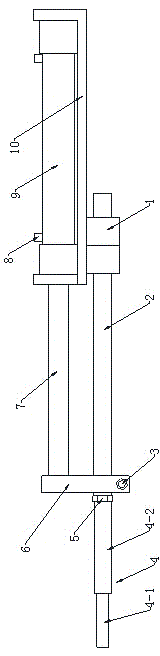

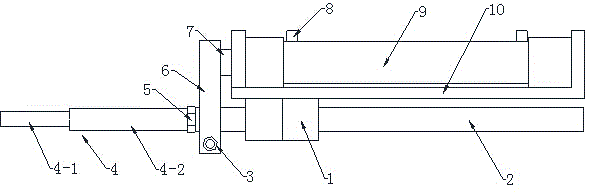

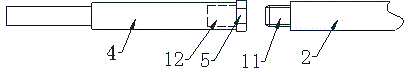

[0015] As shown in the figure, the present invention includes a cylinder 9 and a thimble 4, the cylinder 9 is fixed on the cylinder holder 10, the left end of the cylinder 9 is provided with a cylinder push rod 7, and the bottom of the cylinder holder 10 is provided with There is a guide rod 2, and the outside of the guide rod 2 is covered with a guide and positioning sleeve 1, and the guide and positioning sleeve 1 is fixed below the left end of the cylinder holder 10; the left end of the cylinder push rod 7 and The left end of guide rod 2 is connected and fixed by synchronous fixed block 6, and the left end of described guide rod 2 is provided with screw head 11, and the left side of described synchronous fixed block 6 is provided with thimble 4, and described thimble 4 is fixed on described on the screw head 11.

[0016] In this embodiment, the guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com