Screening Clay Sand Fixing Grass Seeding Machine

A clay and sieving technology, applied in the field of desertification control, can solve problems such as difficult large-scale application, high material and labor costs, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

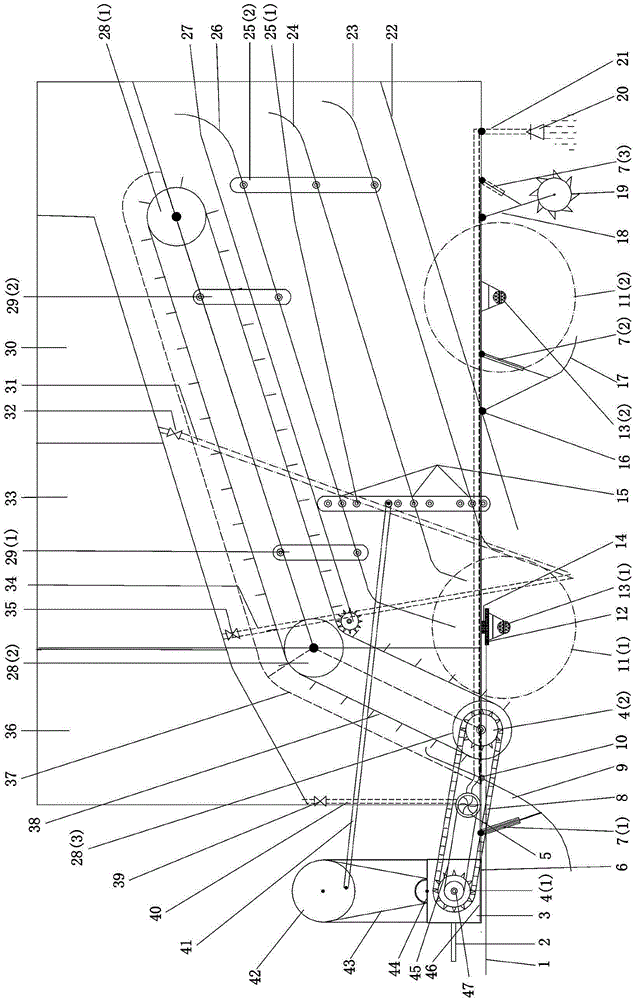

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention.

[0018] Such as figure 1 A kind of sieve-type clay sand-fixing and grass planting machine shown is composed of a sand picking plate 9, a scraper type conveyor belt 38, a conveyor belt retaining sand plate 37, a transmission wheel 28 (1), a transmission wheel 28 (2), and a transmission wheel 28 (3) The collection and delivery device composed of conveyor belt support wheels 27 collects the mixed sand and soil on the upper layer of the dune and transports it to the screening device; the screening device is composed of a screening part and a driving part, and the screening part is composed of a coarse screen Sieve 24, fine sieve 23 and bottom plate 22, sieve group fixing rod 25 (1), sieve group fixing rod 25 (2), sieve g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com