A preloading device for a gear shaft of an air outlet frame

An air outlet frame and gear shaft technology, applied in workpiece clamping devices, metal processing, metal processing equipment, etc., can solve problems such as affecting the normal use of the gear shaft, deformation of the gear shaft, and increasing the labor intensity of the operator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The core of the present invention is to provide a preloading device for the gear shaft of the air outlet frame, so as to reduce the labor intensity of the operator.

[0033] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

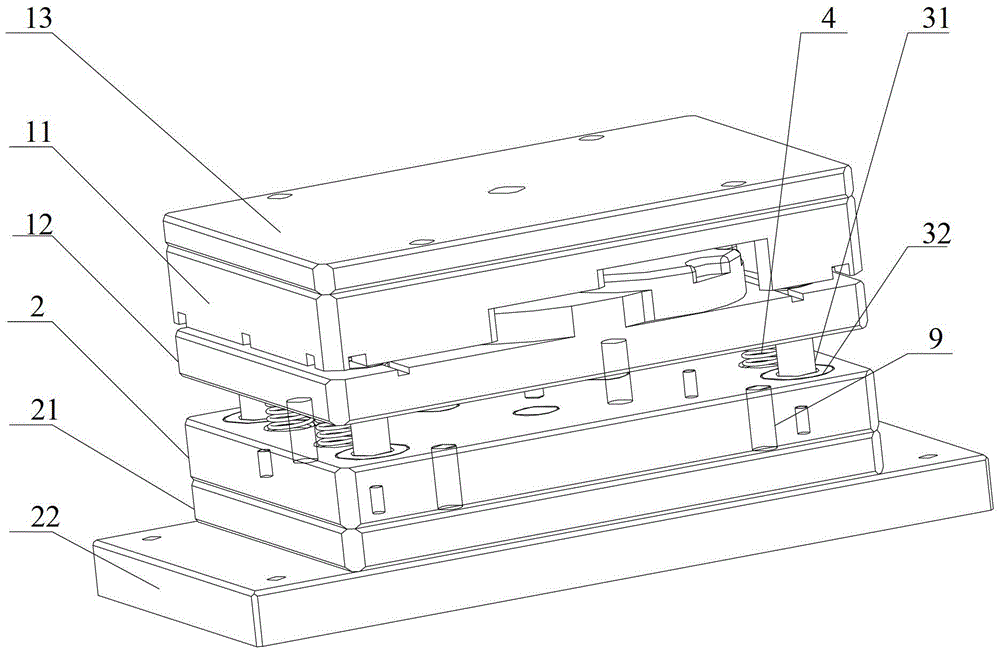

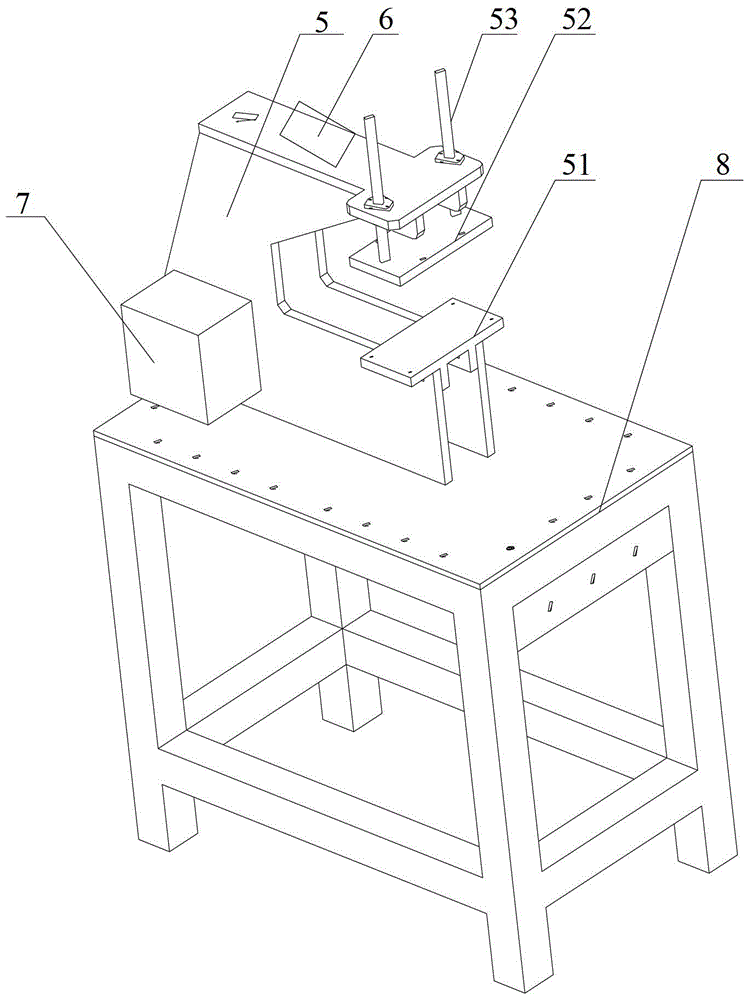

[0034] Please refer to figure 1 with figure 2 As shown, the embodiment of the present invention discloses a preloading device for the gear shaft of the air outlet frame, which is used to install the gear shaft in the installation hole of the air outlet frame, which includes: a clamping piece for fixing the air outlet frame , the clamping piece is provided with a positioning hole opposite to the mounting hole of the air outlet frame and used for setting the gear shaft: the bottom mold 2 arranged opposite to the surface where the positioning hole is located; used to driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com