Slat conveyor for extraction systems and transport plates therefor

A technology for conveyors and transport boards, applied in the field of apron conveyors and transport boards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is a detailed description of exemplary embodiments of the present invention. The exemplary embodiments described therein and shown in the drawings are intended to teach the principles of the invention and enable one of ordinary skill in the art to make and use the invention in many different environments and for many different applications. Accordingly, the exemplary embodiments are not intended, and should not be considered, as a limiting description of the scope of patent protection. Rather, the scope of patent protection shall be defined by the appended claims.

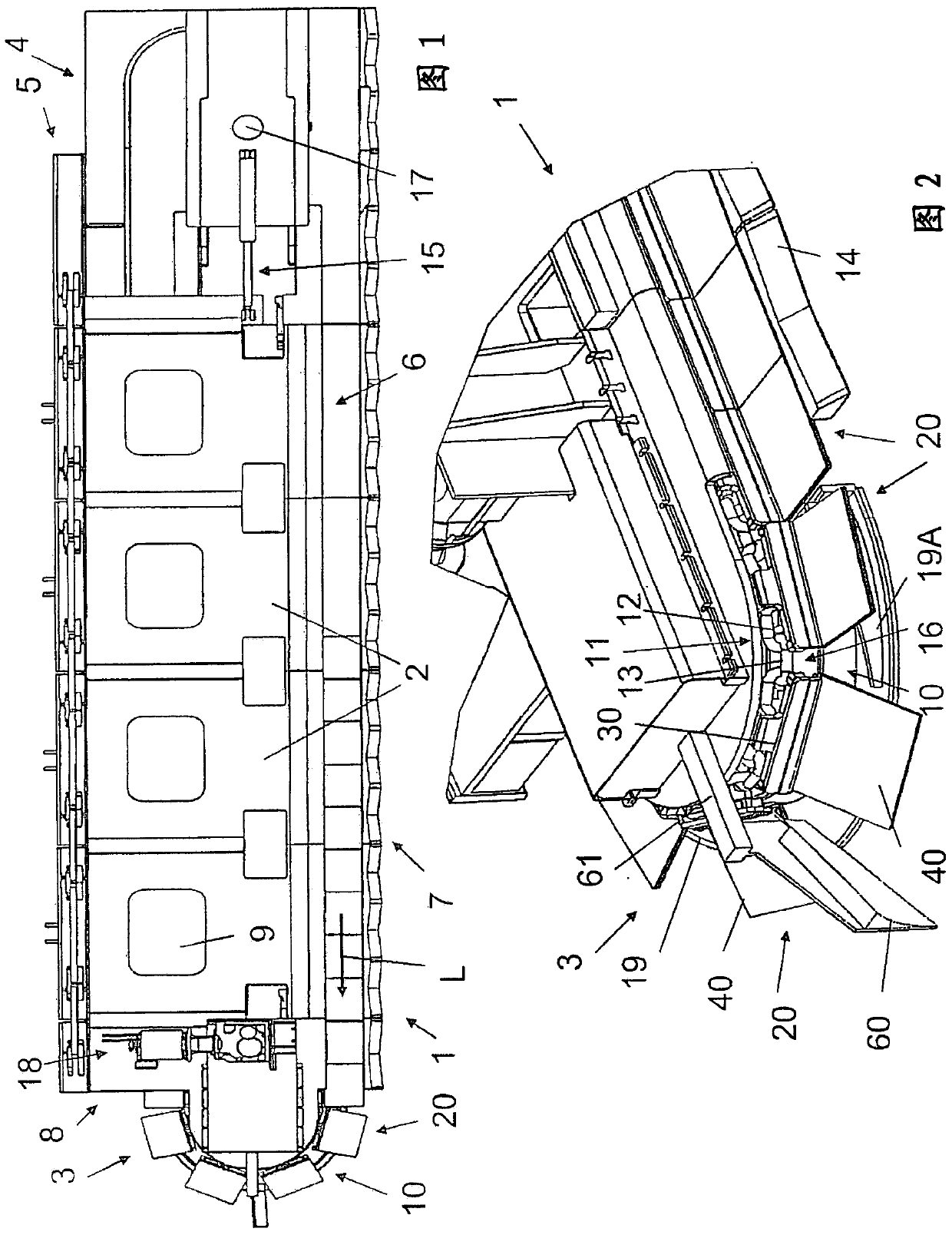

[0024] The slat conveyor according to the invention is in figure 1 The whole is schematically simplified with the reference number 1 in . In this exemplary embodiment, the slat conveyor (skirt conveyor) 1 includes a plurality of channel elements 2, such as figure 1 4 channel elements 2 that are constructed identically to one another are shown in . The four channel elements 2 are preferably ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com