Spline surface processing method applied to fusion reactor neutron transport computation and based on equipotential surface

An isosurface and reactor technology, applied in image data processing, instruments, etc., can solve problems such as failure of neutron transport calculation and ignoring CAD models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

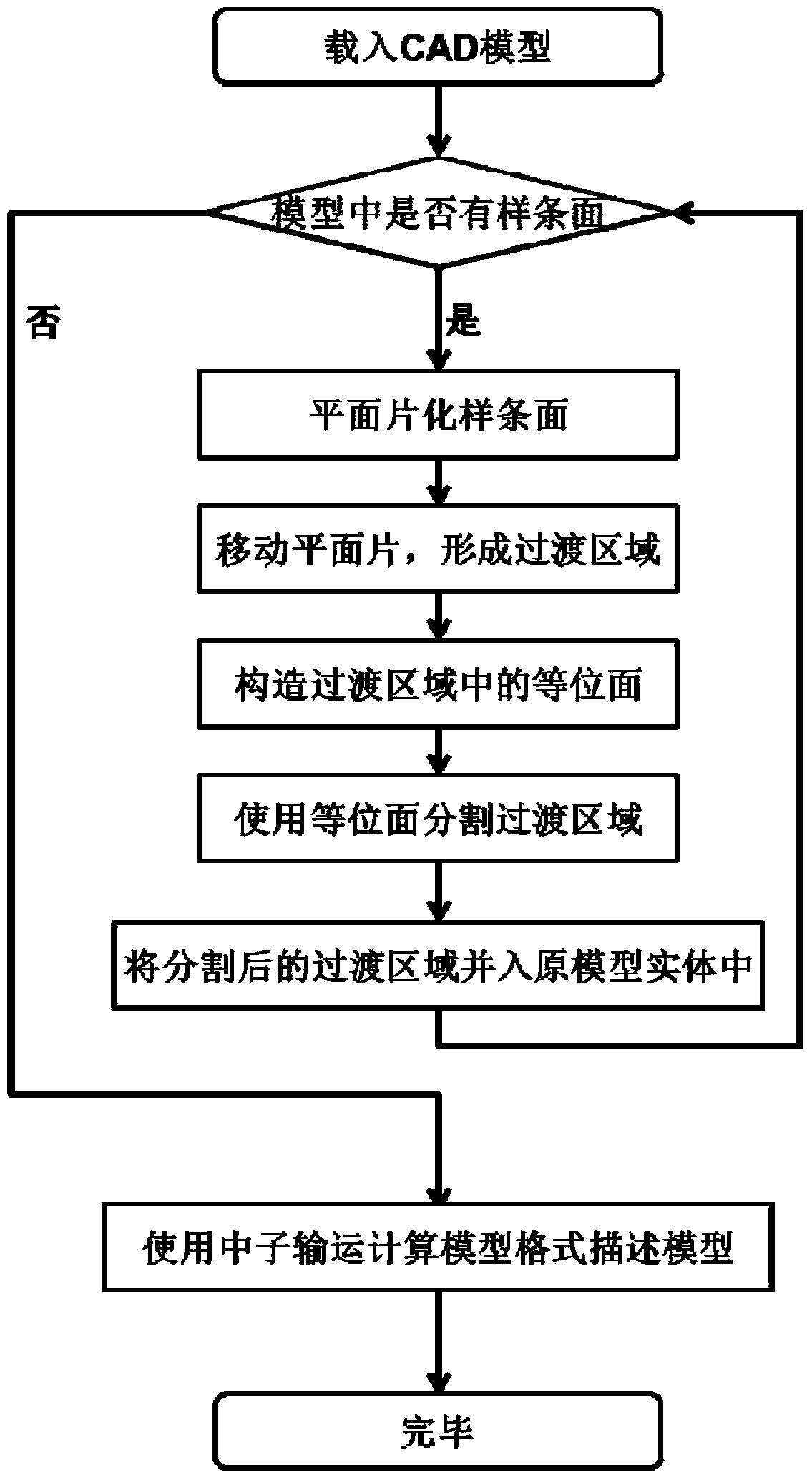

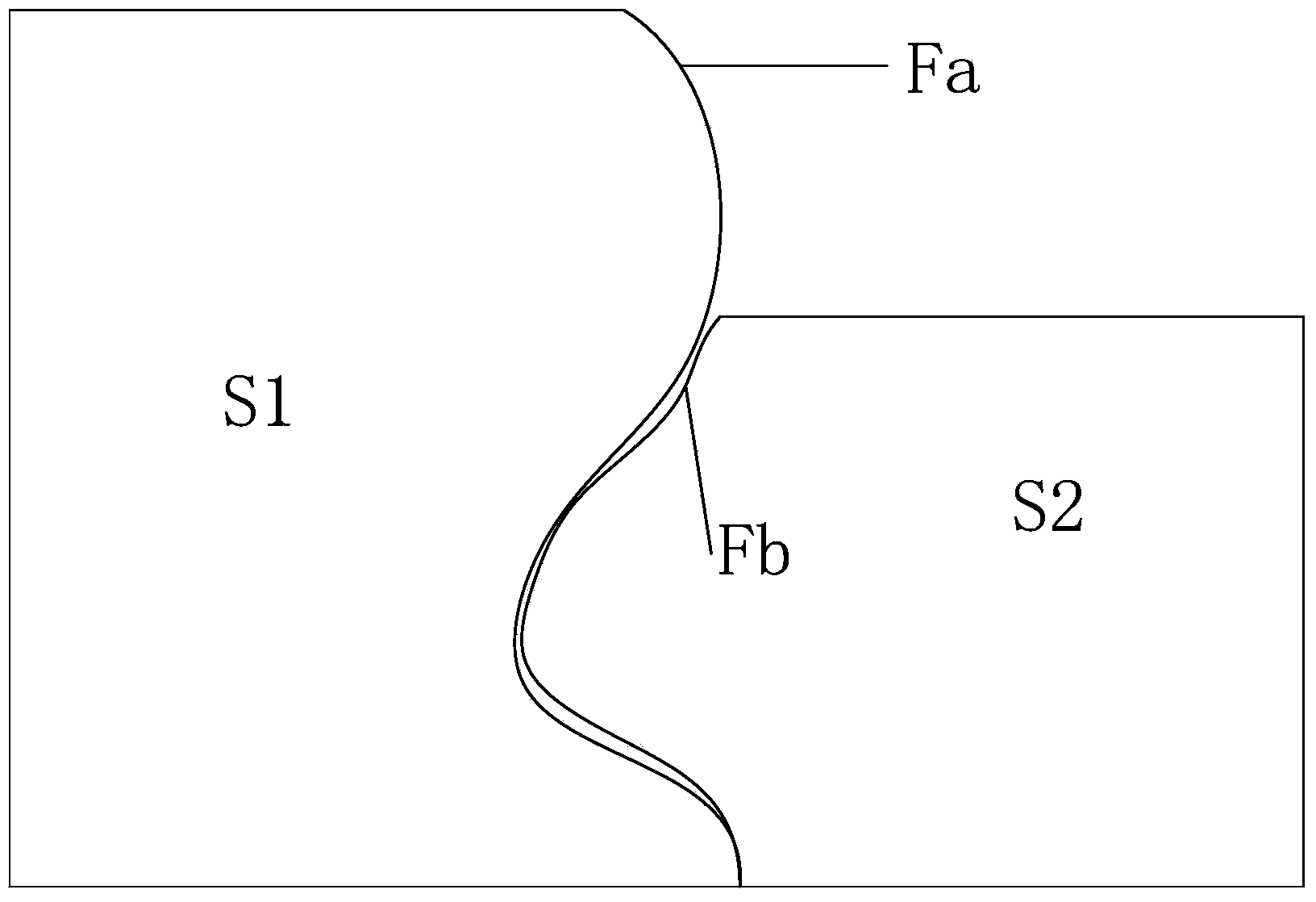

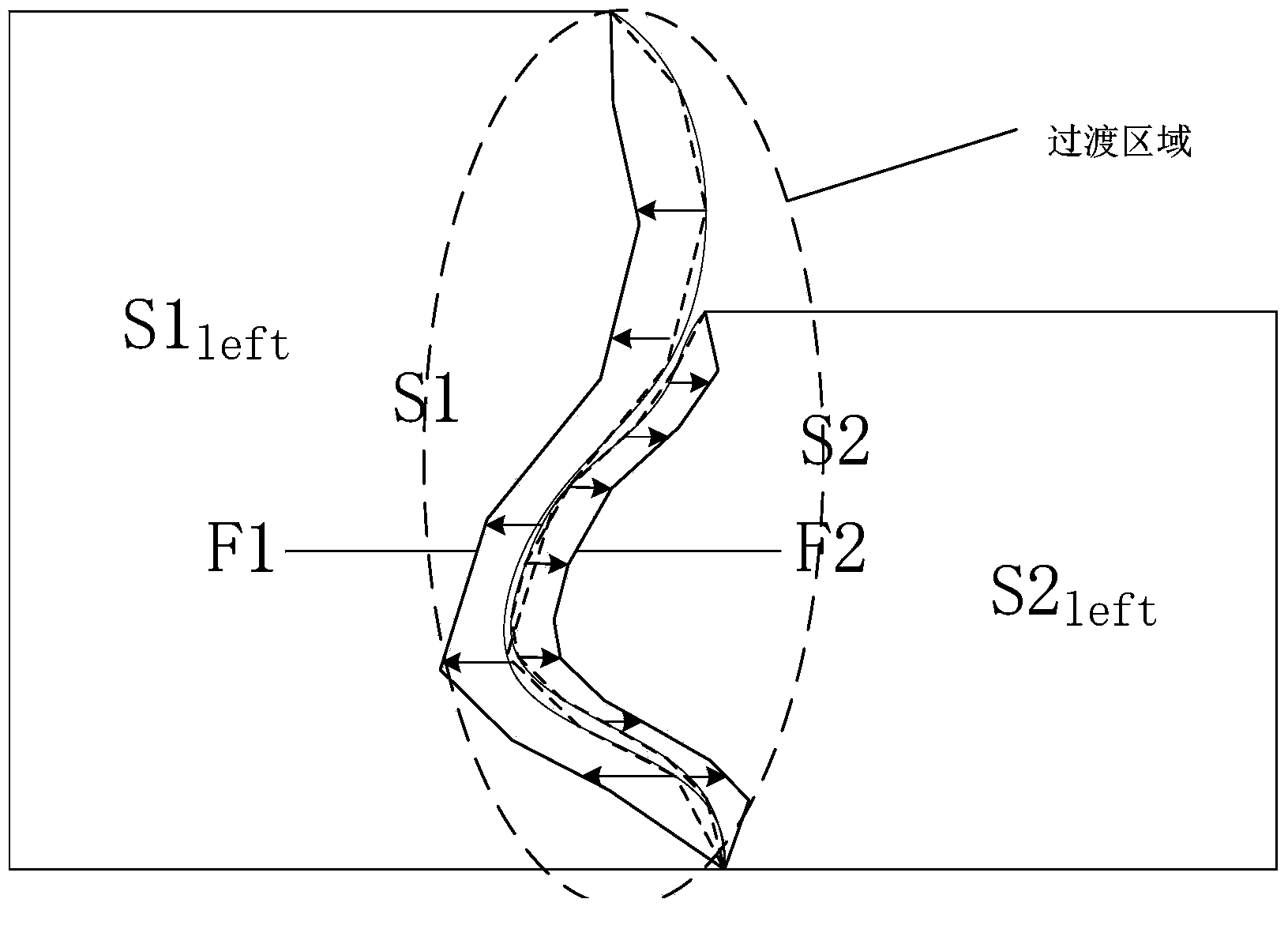

[0020] In order to establish a physical calculation model based on the actual CAD model, it is necessary to solve the problem of simplification of adjacent spline surfaces existing in the actual CAD model. Simplified results cannot contain interference, voids, etc. For this reason, the adjacent spline surfaces between CAD entities need to be simplified through the following steps.

[0021] 1. Assume that Fa and Fb are two adjacent spline surfaces of geometry S1 and S2, and set the parameter equations of the spline surface as follows:

[0022] x=fx(u,v), y=fy(u,v), z=fz(u,v), select the values of parameters u and v at a certain interval, and obtain a set of vertices on the spline surface, At the same time, the values of parameters u and v are selected at certain intervals on the edges of the spline surface to obtain a group of vertex sets on the edges of the spline surface. Connect the adjacent three vertices of these vertices to form a plane piece, and connect the plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com