Device and method for measuring ultrasonic power in a semi-anechoic water tank

A technology of ultrasonic power and measurement method, applied to measurement devices, vibration measurement in fluid, measurement of vibration and other directions, can solve problems such as affecting calibration results, inability to intercept radiated sound waves, and inability to confirm the distance between the transmitter and the reflective target, and achieve calibration. Accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

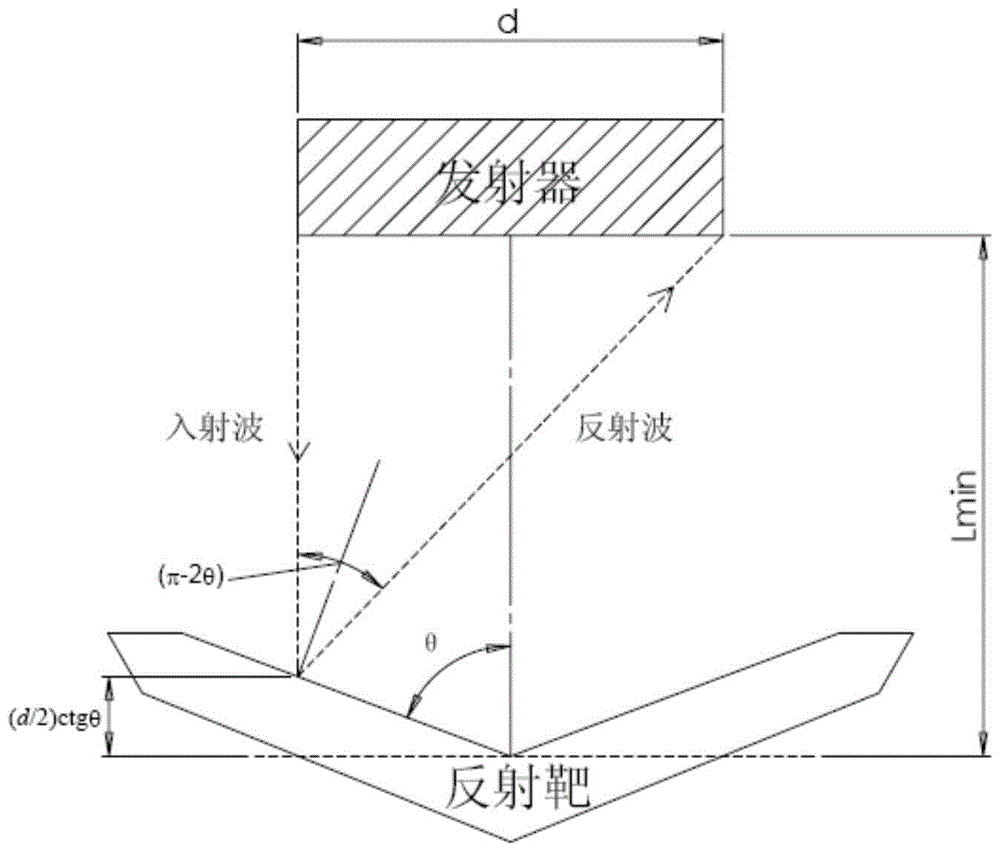

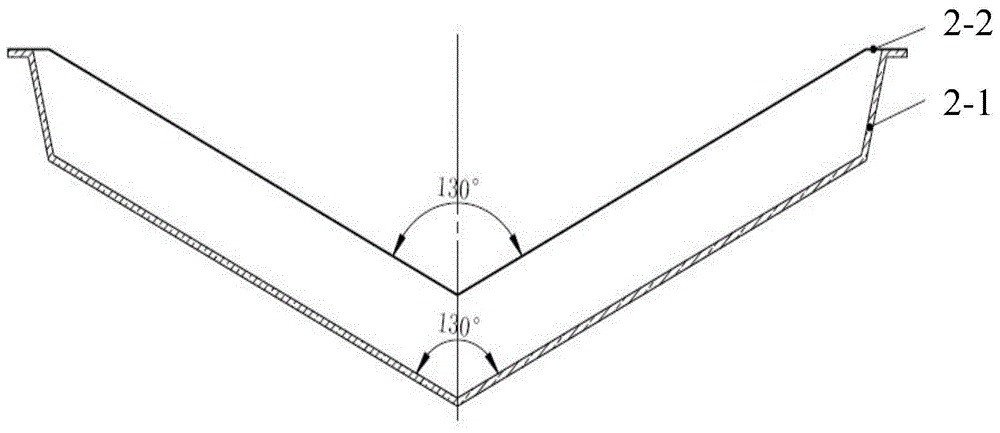

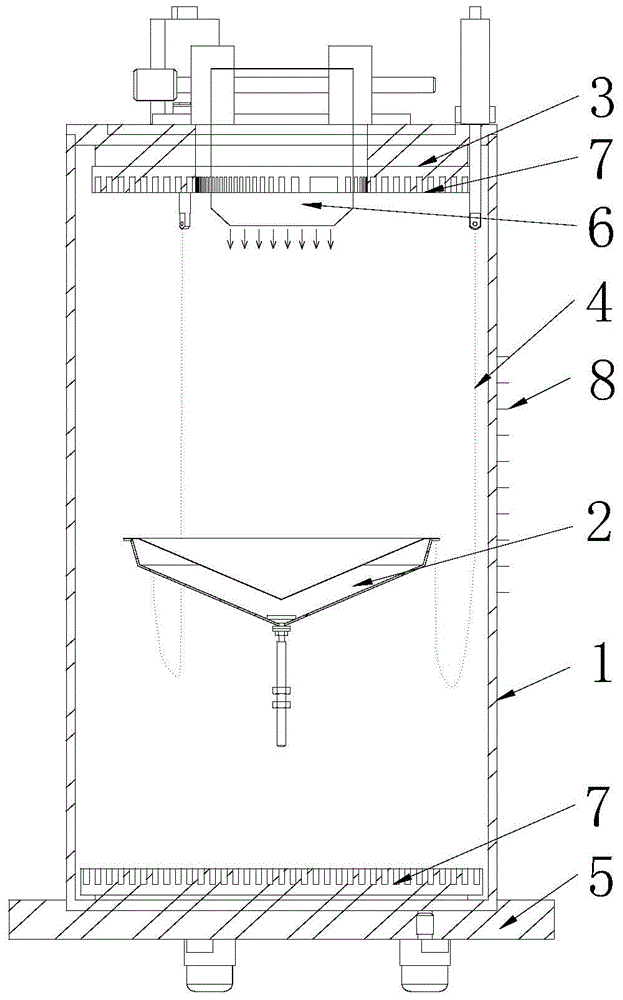

[0027] Such as Figure 1-3 As shown, the device for measuring ultrasonic power in this semi-anechoic water tank realizes the measurement of ultrasonic radiation sound power. The upper and lower inner surfaces are pasted with sufficient sound-absorbing materials, and the cylindrical water tank with smooth, transparent and untreated side walls uses reflection targets Ultrasonic power measurement in this water tank has the remarkable characteristics of being able to confirm the initial state of the target in all directions, observe the measurement process in real time, and improve measurement effectiveness and work efficiency. It mainly includes a semi-sound-absorbing water tank 1 and electronic instruments. The semi-sound-absorbing water tank 1 includes a transparent round tube with a scale line 8, an upper cover 3 and a lower cover 5. No sound-absorbing materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com