Claw disc mechanism of noodle grabbing machine

A technology of claw plate and noodle machine, which is applied in the fields of dough processing, baking, food science, etc., and can solve the problems of conveying noodle blocks and placing noodle blocks that need to be further improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

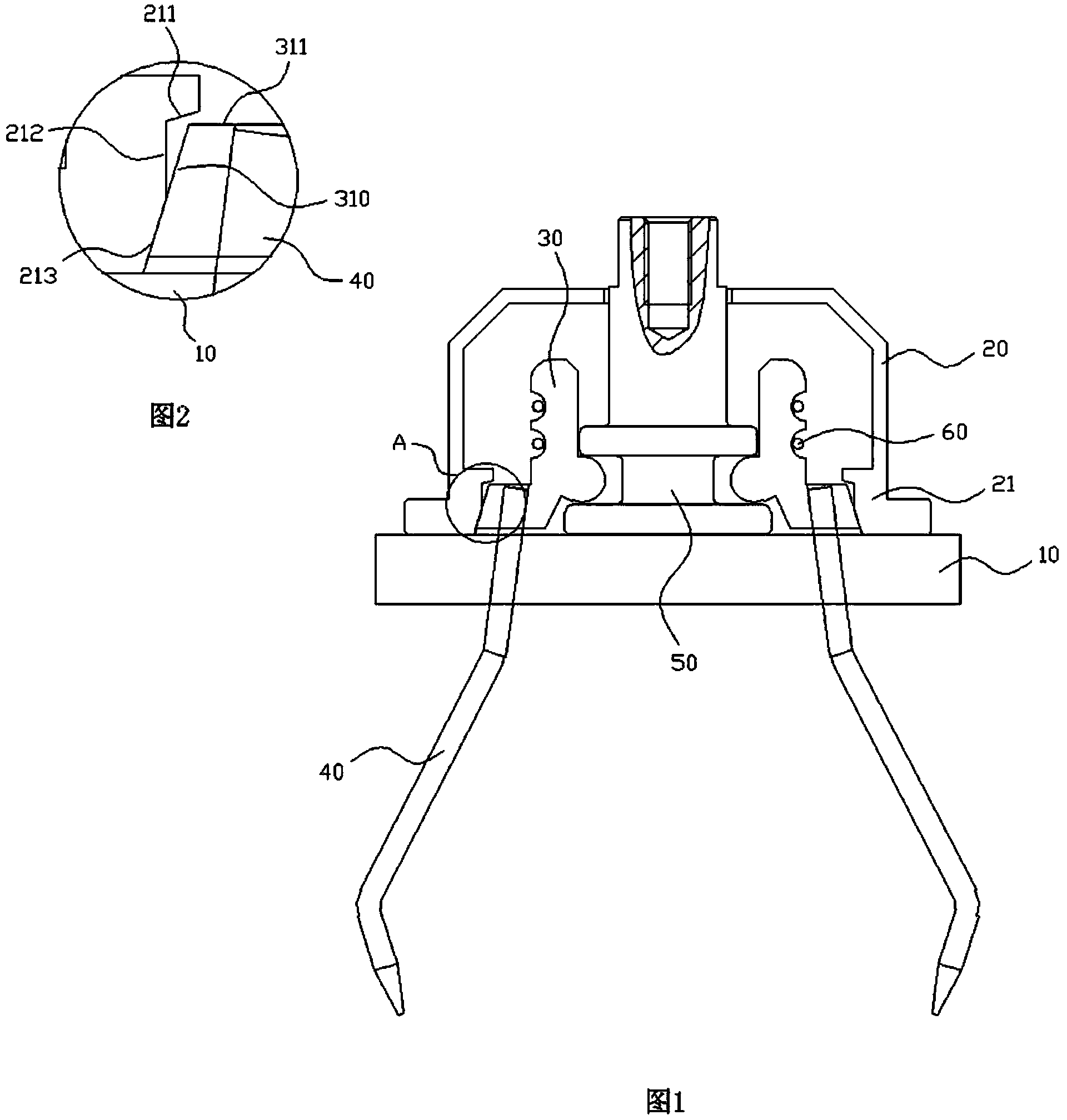

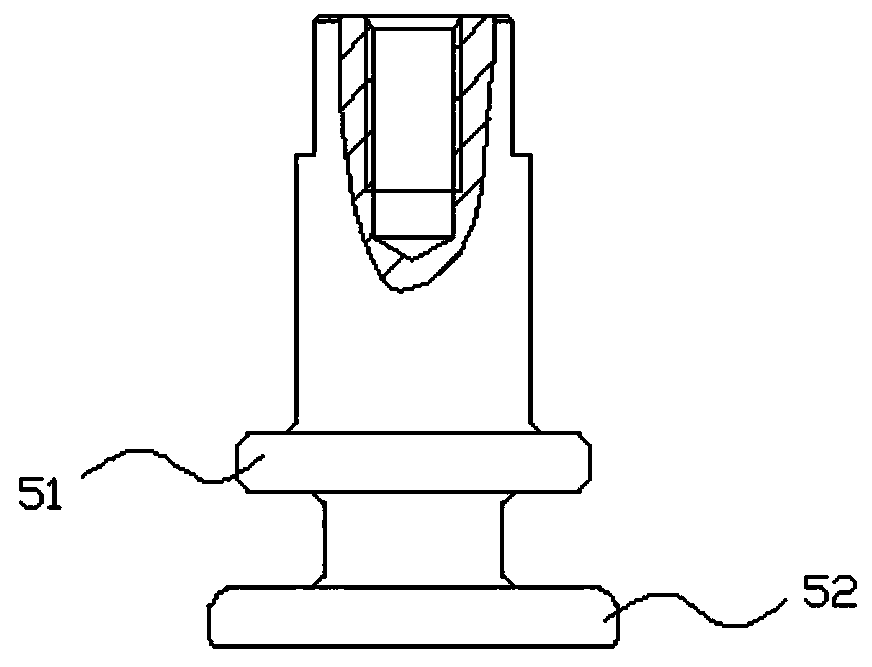

[0024] Such as figure 1 As shown, a claw plate mechanism of a noodle grasping machine includes a main board 10, a cylindrical shell 20 installed on the main board 10, a claw plate block 30 located in the shell 20, and a claw hand 40 tightly embedded on the claw plate block 30. , Cylindrical movable core 50.

[0025] Such as figure 1 As shown, claw holes are opened on the main board 10 , and the claw hands 40 extend out of the main board 10 along the claw holes.

[0026] Such as figure 1 As shown, the top of the housing 20 is provided with a through hole. The contact between the housing 20 and the main board 10 is provided with an inward protrusion 21, such as figure 2 As shown, one side of the housing protrusion 21 is an irregular stepped slope, and the stepped slope includes a first slope 211, a vertical surface 212 connected with the first slope 211, and a vertical surface 212 The conjoined second inclined surface 213 .

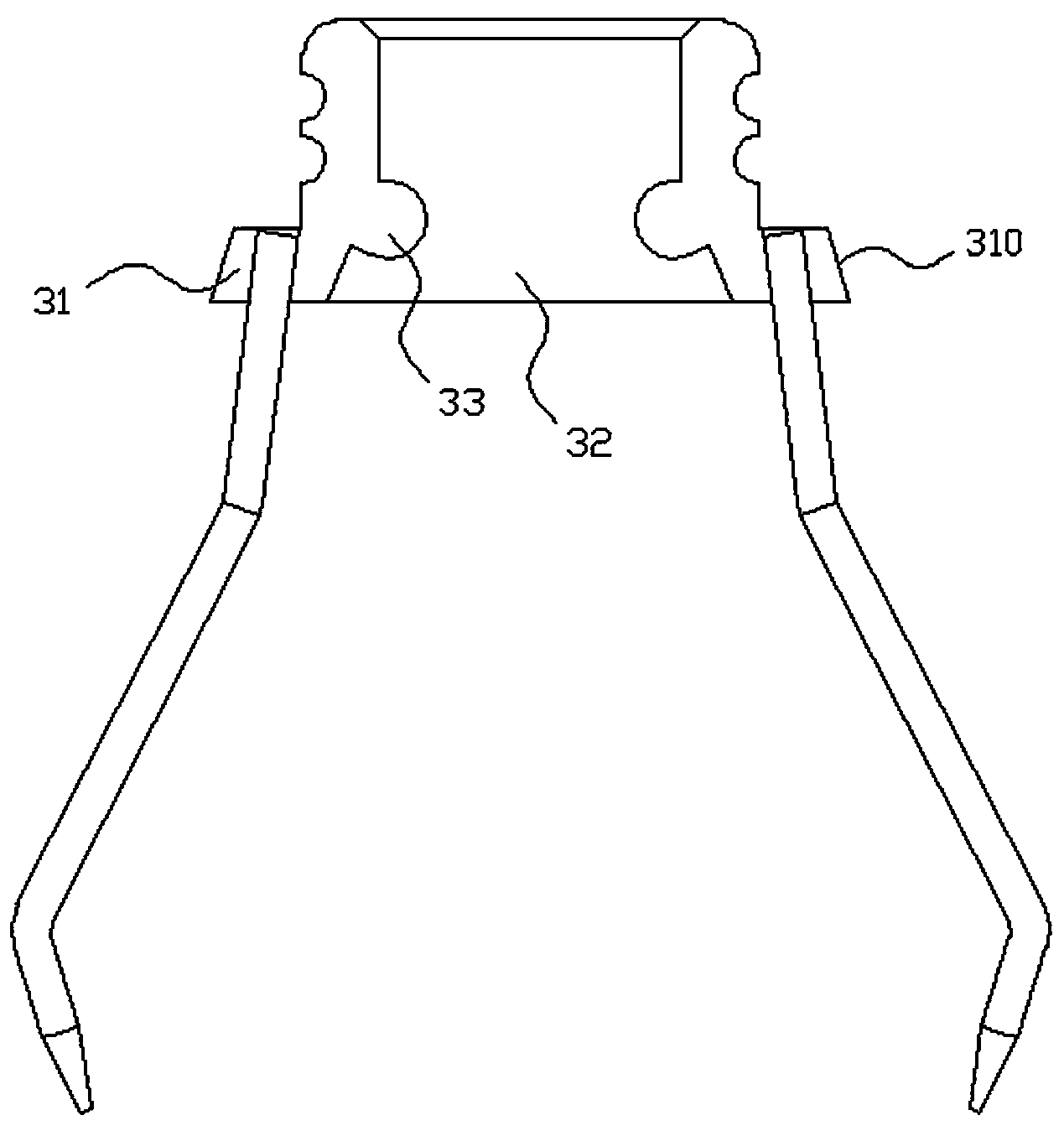

[0027] Such as image 3 As shown, the claw pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com