Feeder for crushing of crop straw material

A crop straw and feeder technology, which is applied to animal feeding devices, applications, animal husbandry and other directions, can solve the problems of inability to achieve uniform and continuous feeding, affecting the conveying performance of conveying devices, irregular size and shape, etc. Simple, convenient operation and use, improve the effect of conveying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

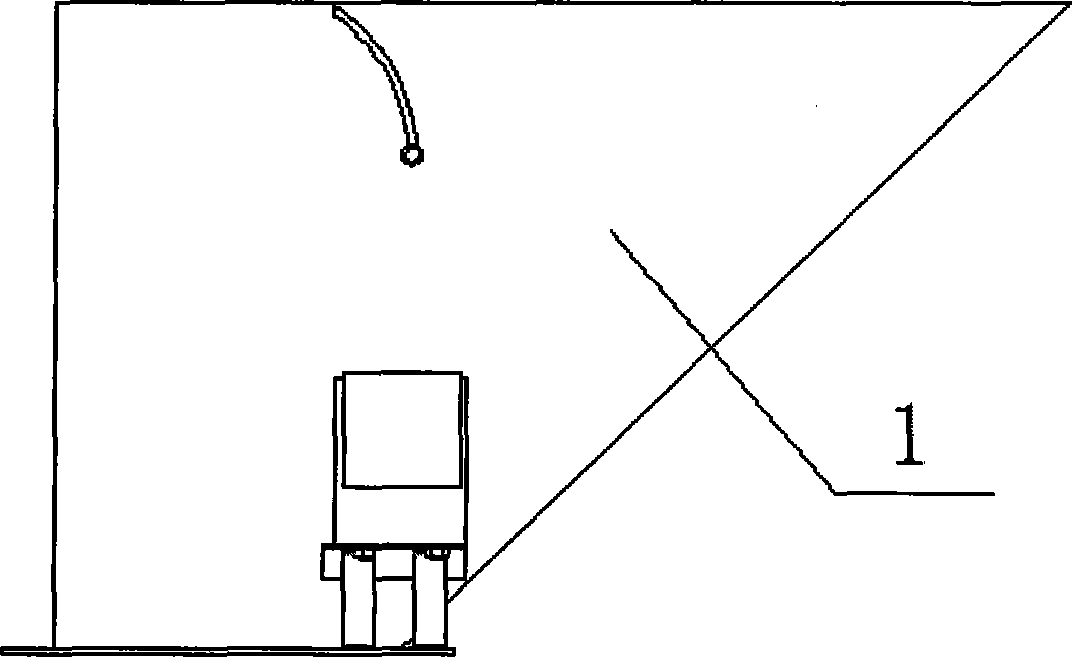

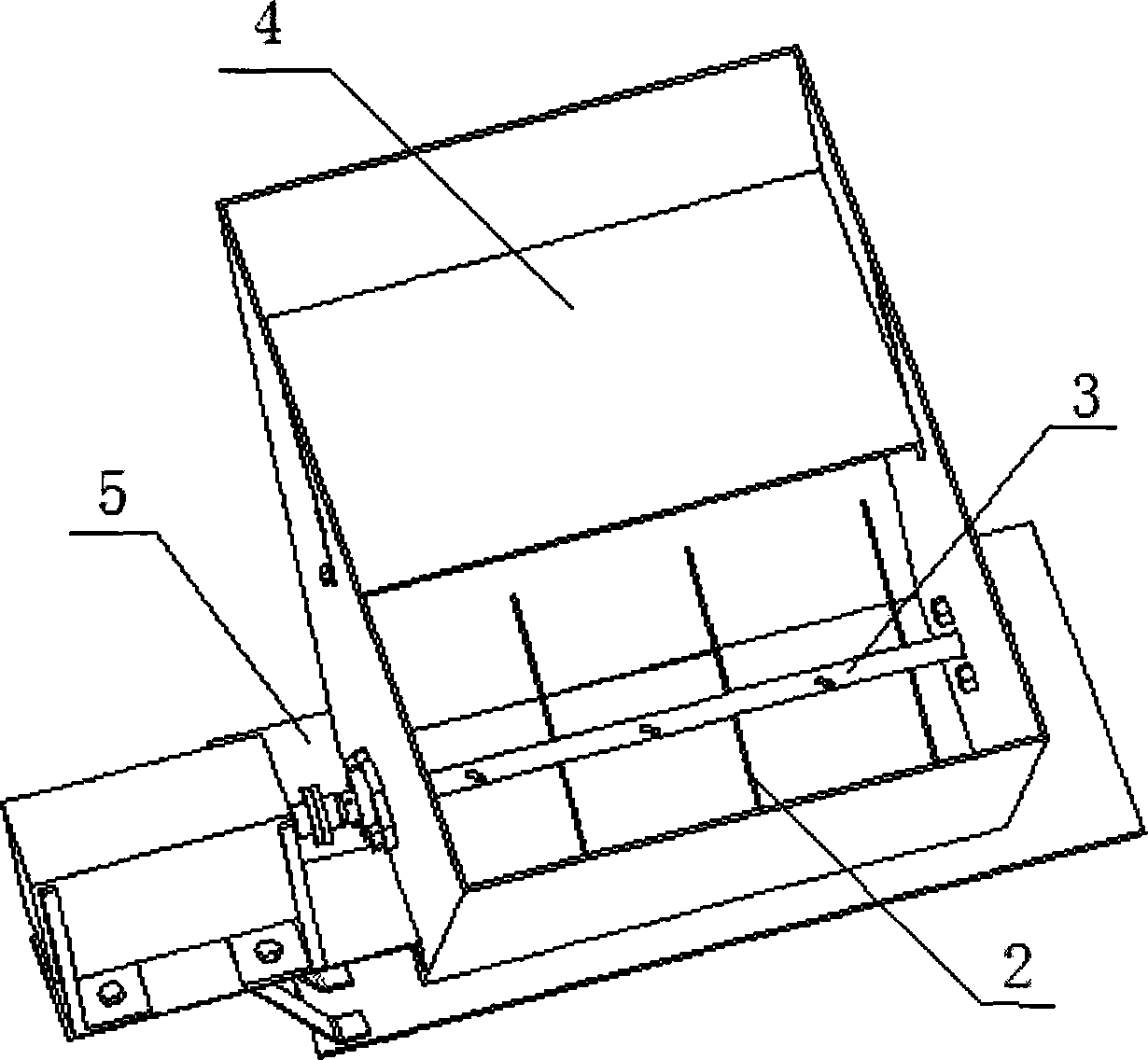

[0020] Feeding hopper 1 is shaped like Figure 1-3 As shown, one side is made to be vertical, and the other side is made to have an angle of 45° with the horizontal plane. The selection basis is that the sliding friction angle is 45° when the moisture content of the crushed straw is about 75%, and the sliding friction angle is less than 45° when the moisture content is less than 75%.

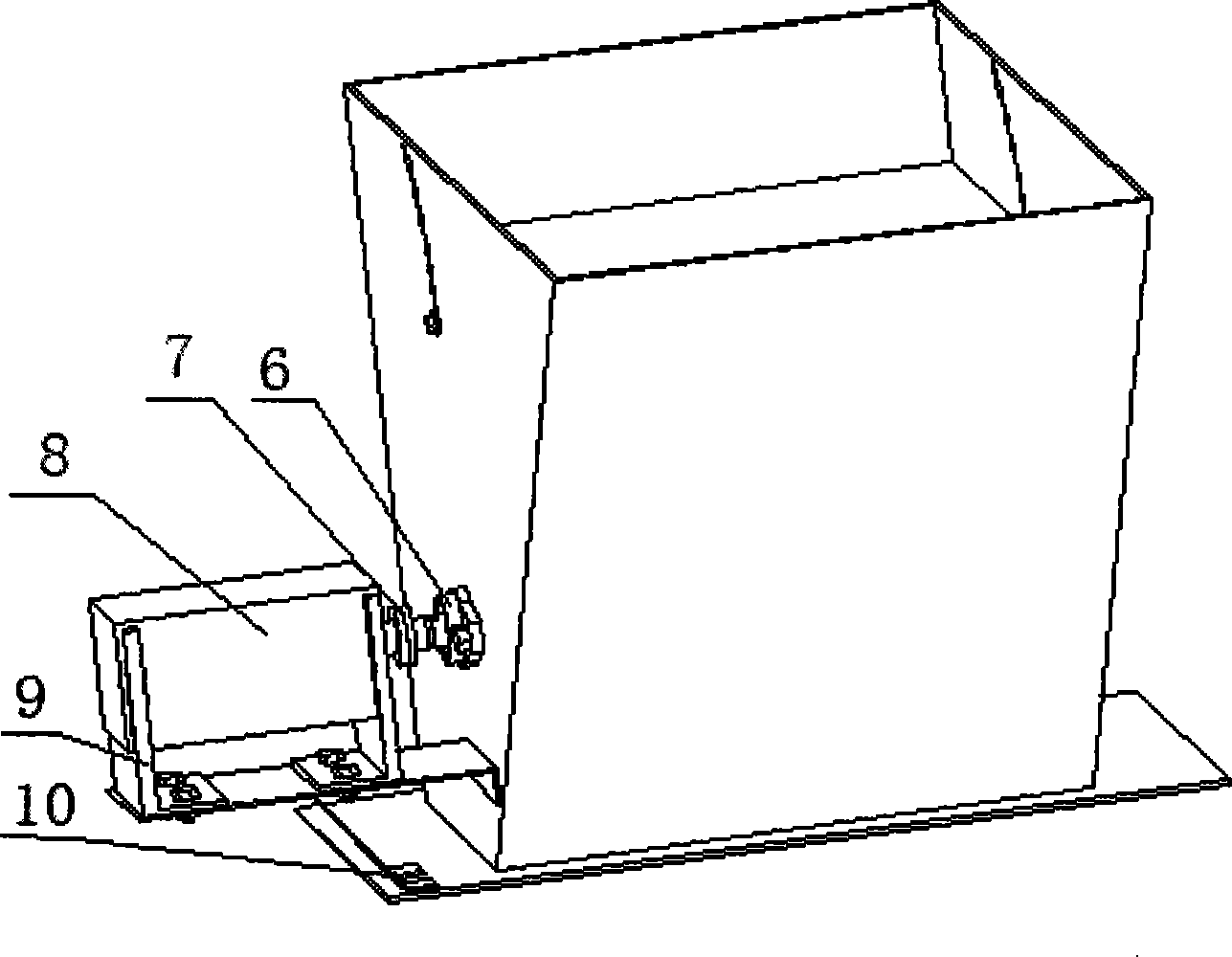

[0021] The feeding hopper 1 is fixed on the feeding place of the screw conveying device with bolts, the rotating shaft 3 is inserted on the feeding hopper 1, and the two ends of the rotating shaft 3 are fixed with the feeding hopper 1 with bearings. Holes are staggered at 90° on the rotation axis 3, and the elastic teeth 2 are welded and fixed in the holes. The significance of the adjacent elastic teeth 2 staggering 90° from each other and fixed on the rotating shaft 3: on the one hand, it can prevent the long crushed straw from winding on the rotating shaft; The baffle plate 4 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com