Grass trimmer and grass trimming head thereof

A technology of cutting head and cutting machine, which is applied in the directions of hand-held lawn trimmers, harvesters, lawn growth, etc., can solve the problems of wear of the beating head, influence of motor performance, and increased power consumption of the grass cutting machine, etc. Achieve the effect of avoiding load increase, prolonging service life and reducing output power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

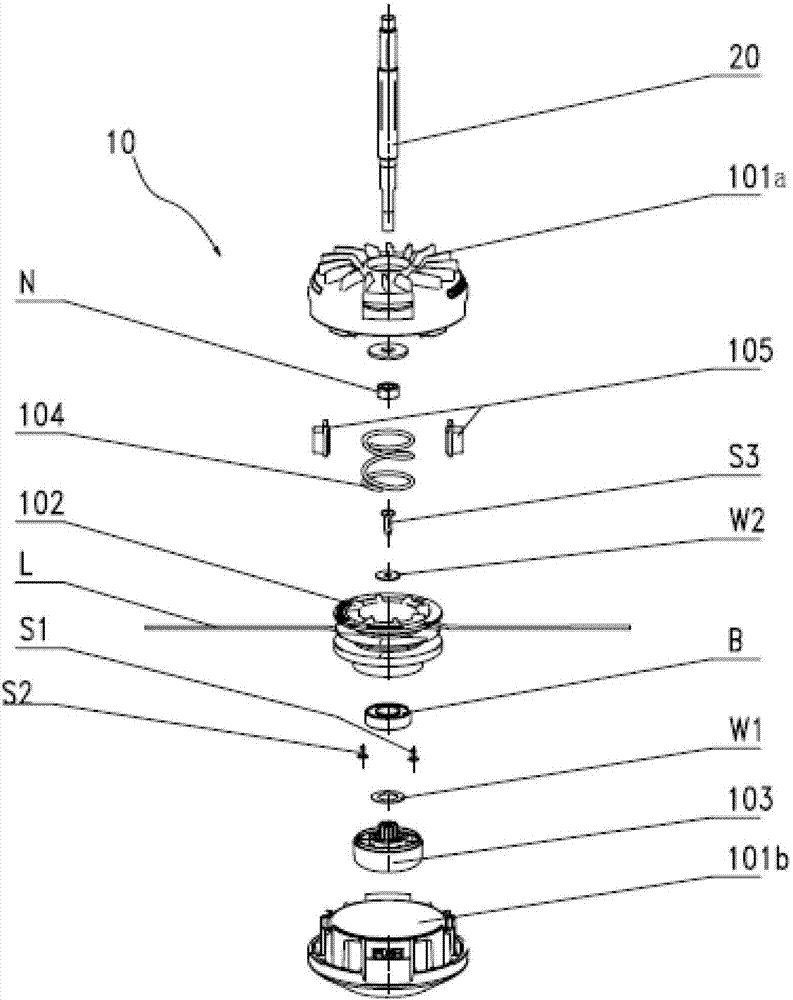

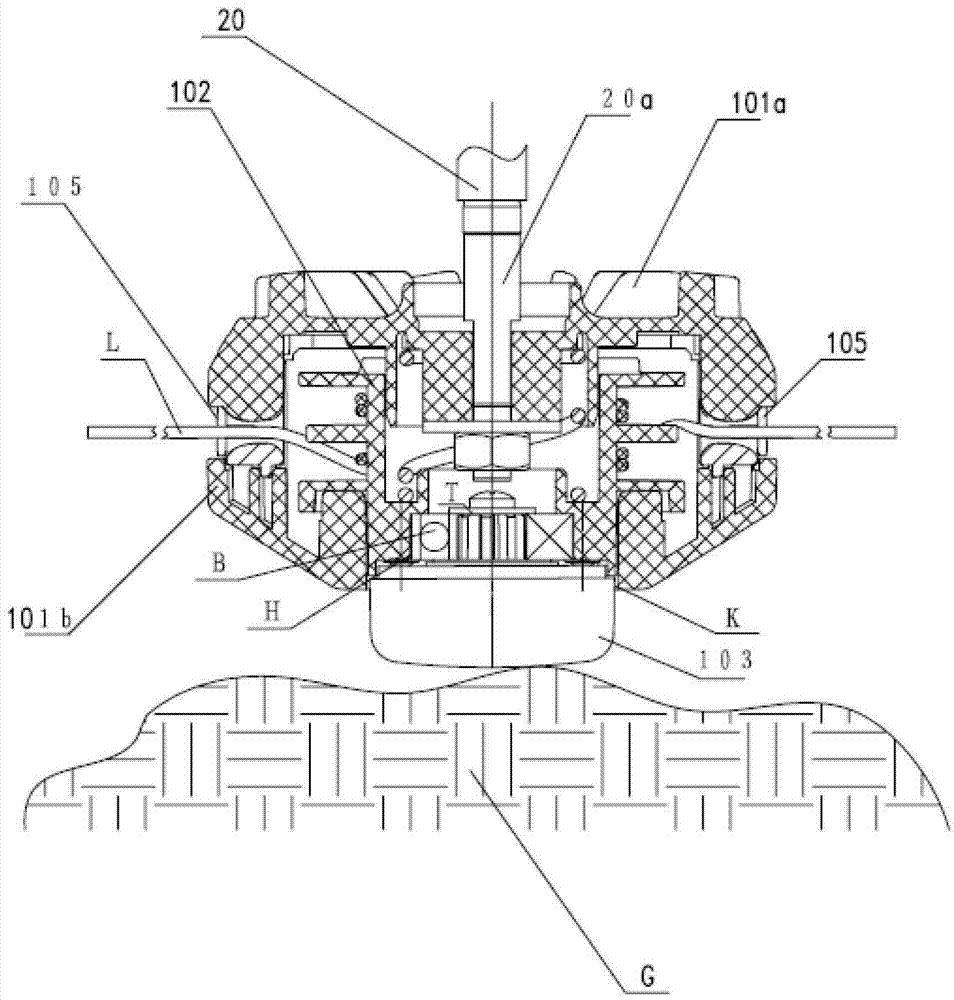

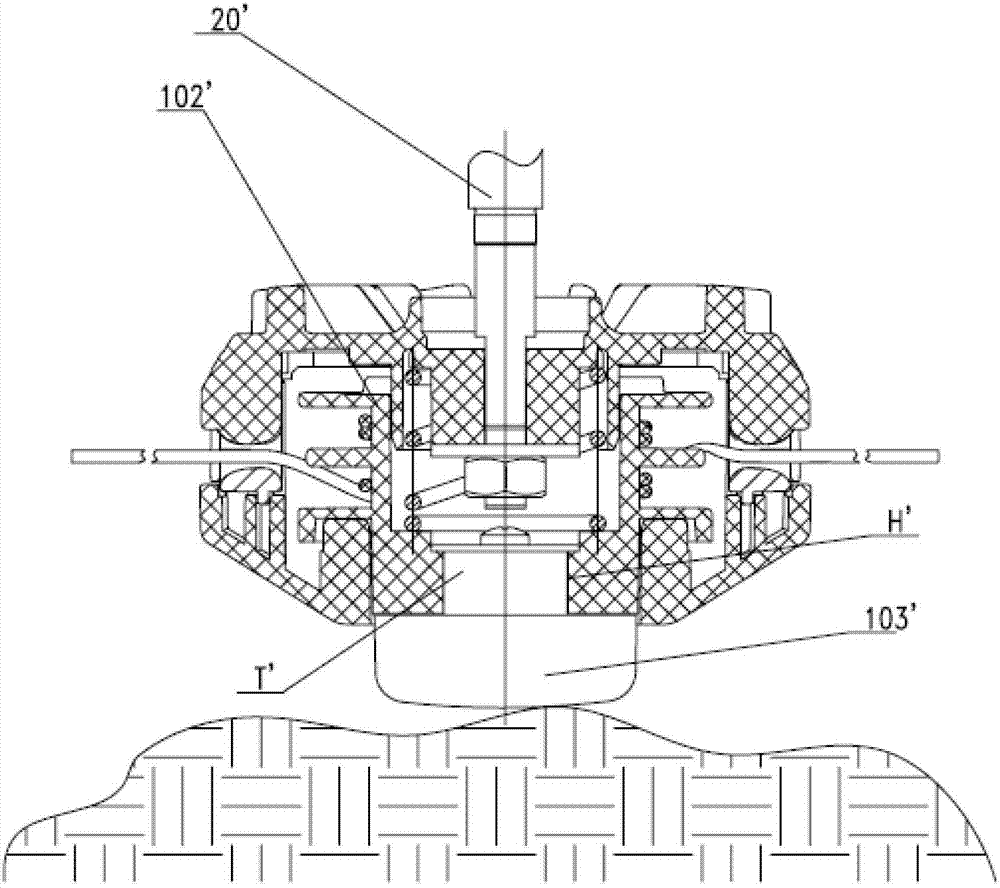

[0028] figure 1 Shown is the three-dimensional exploded view of the grass cutting head of the first embodiment of the present invention, figure 2 for figure 1 Partial cross-sectional view of the grass cutting head assembled in figure 1 with figure 2 , wherein the parts except the motor shaft and the percussion cap are sectioned, and the mowing head 10 is connected to the motor output shaft 20 of the mowing machine.

[0029] The mowing head 10 includes: a housing 101 , a winding shaft 102 , a support cap 103 and a compression spring 104 . In this embodiment, the housing 101 includes an upper cover 101a and a lower cover 101b that are fixedly engaged with each other, and the upper cover 101a is mounted on the end 20a of the motor output shaft 20 through a nut N, and the lower cover 101b has an opening K. The winding shaft 102 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com