A manufacturing process for digitally customized bone implants

A manufacturing process and implant technology, applied in the direction of bone implants, etc., can solve the problems of incompatibility of implant positions, rough bone implants, and long production cycle, so as to improve the production efficiency, improve the precision, and simplify the steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

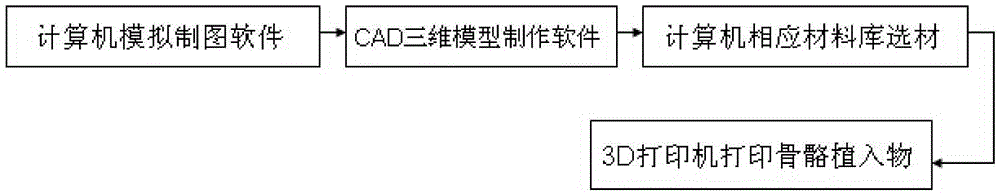

[0012] combine figure 1 It can be seen that a manufacturing process of digitally customized bone implants, the specific steps are:

[0013] (1) First use the computer simulation drawing software to simulate the healthy state diagram of the bone when it is not damaged, and then combine the state diagram of the damaged bone waiting to be implanted to simulate the shape diagram of the bone to be implanted; this step is more critical and directly affects to follow-up steps;

[0014] (2) Then use the computer CAD three-dimensional model making software to draw a complete three-dimensional figure of the bone form to be implanted; the steps are based on the step (1), if the step (1) is not done well, The model produced in this step will be deviated or even scrapped;

[0015] (3) Next, use the corresponding material library of the computer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com