Extended cascade plasma gun

A plasma gun, neutral pole technology, applied in the field of ion guns, can solve the problems of few tests and lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

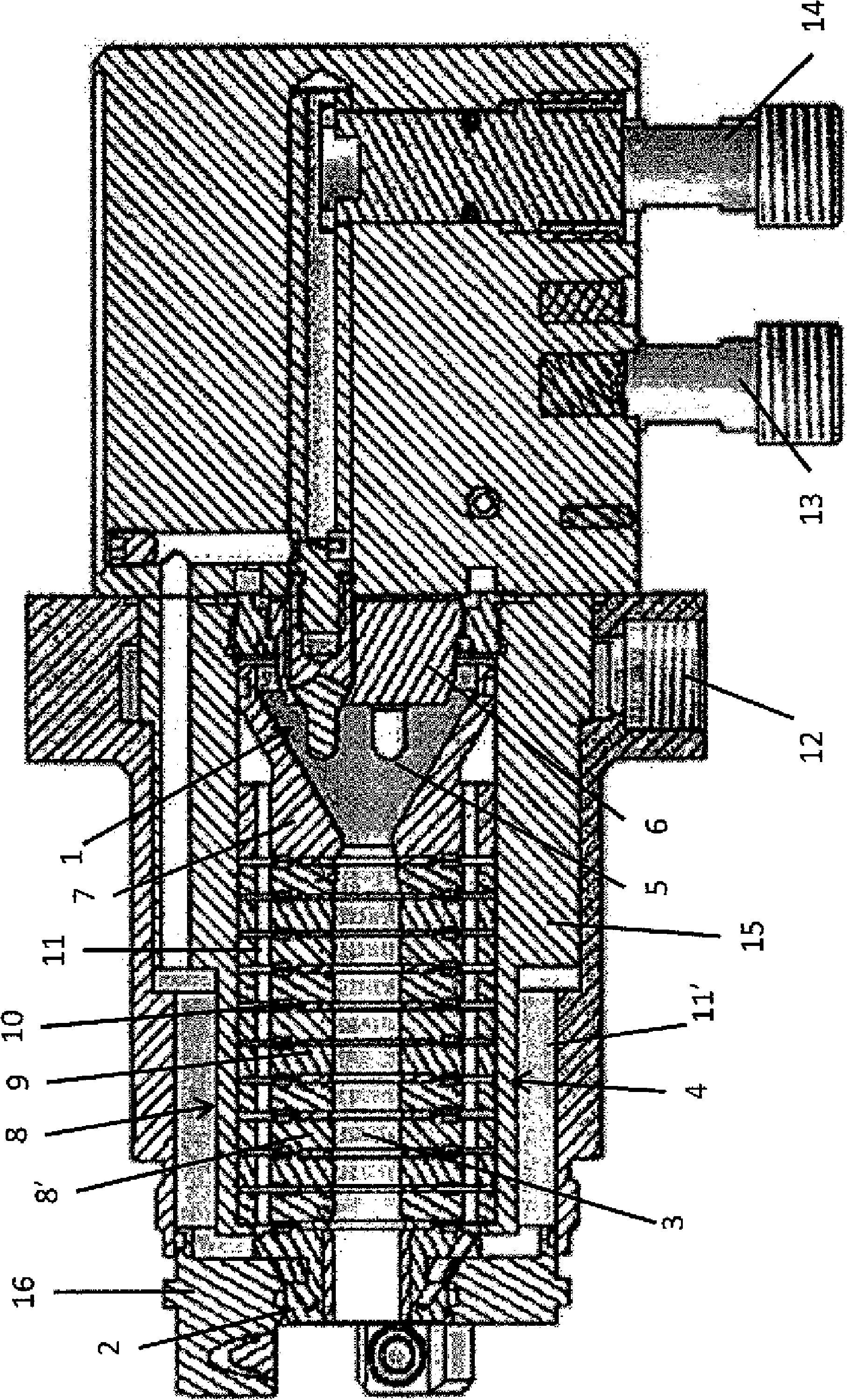

[0027] The details shown here are by way of example only and discussions for the purpose of illustrating embodiments of the invention, and are presented in the course of providing what are believed to be the most useful and understandable description of the principles and concepts of the invention. In this regard, no attempt is made to show the structural details of the invention in more detail than is necessary for a basic understanding of the invention, and the description in conjunction with the accompanying drawings will make apparent to those skilled in the art several ways in which the invention can actually be embodied .

[0028] figure 1 The shown plasma spraying device comprises a cathode assembly 1 and an anode 2 separated by a plasma channel 3 defined by the annular interior of a neutral pole (neutrode) assembly 4 also called channel hole.

[0029] By way of non-limiting example, the cathode assembly 1 may comprise a plurality of cathodes 5, for example three cath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com