A method for measuring the profile of bearing rollers with cages

A technology of bearing rollers and detection methods, applied in the direction of electric/magnetic profile/curvature measurement, electromagnetic measurement devices, etc., can solve the problems of complex bearing wear trend analysis, difficult bearing wear state reuse life, etc., to achieve convenient multi-roller The effect of detecting, preventing bumps and shortening the detection cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiment of the invention discloses a device for detecting the profile of a bearing roller with a cage. The portable profile measuring instrument can be fixed and assembled simply and quickly, and improves the reliability and measurement stability of the profile detection of the bearing roller with a cage. .

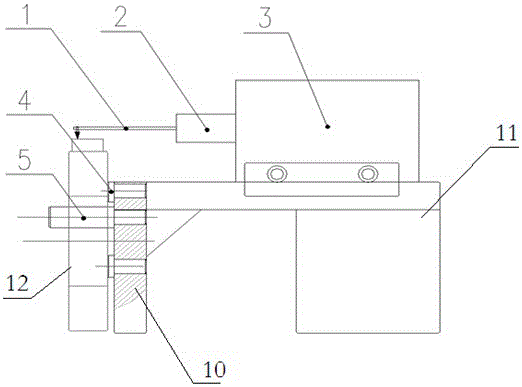

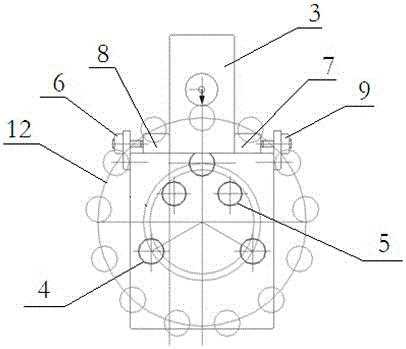

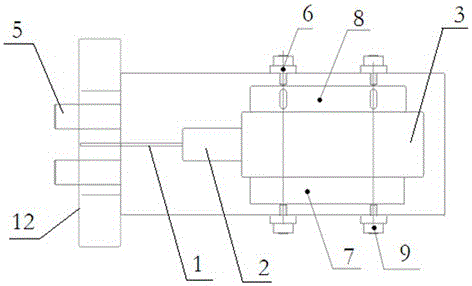

[0040] Such as Figure 1 to Figure 3As shown, a roller profile detection device with a cage includes a portable measuring instrument and a fixing device. The portable measuring instrument includes a measuring needle 1, a sensor 2, and a driving box 3. The sensor is connected to the driving box, and the measuring needle is connected to the sensor. . The fixing device includes a bearing positioning and fixing device and a portable measuring instrument fixing device, and the bearing positioning and fixing device includes a support frame 10, three stop pins 4, and two support pins 5, and the support pins and stop pins are all installed on the support frame , T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com