Device and method for washing needle cylinders

A syringe and cleaning mechanism technology, applied in the field of syringe washing devices, can solve problems such as safety accidents, occupational injuries, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

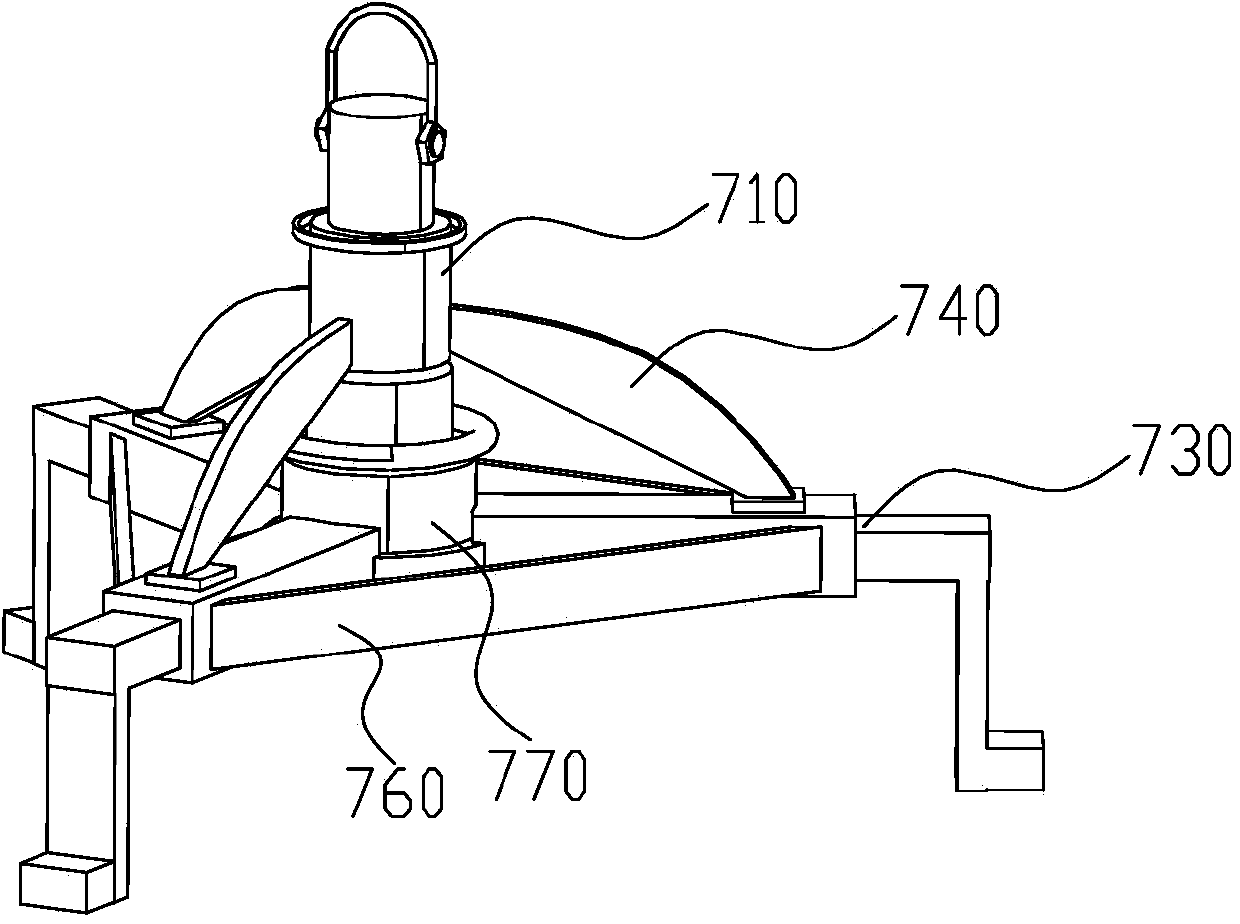

[0032] Such as figure 1 As shown, a device for washing needle cylinders includes a lifting mechanism, an autorotation mechanism, and a cleaning mechanism. The autorotation mechanism includes a motor and a turret 1 connected to the motor. The oil gun 3 on the rod 2, the lifting rod 2 is arranged on the side of the turret 1, the lifting mechanism includes a bracket 4, a rotating arm 5, an electric hoist 6 with a sling 610, a clamp 7 and the rotating arm 5 It is rotatably arranged on the bracket 4 , the electric hoist 6 is arranged on the rotating arm 5 , and the clamp 7 is connected with the suspension rope 610 of the electric hoist 6 .

[0033] The device for washing the needle cylinder described in this embodiment can realize the lifting, moving, and dropping of the needle cylinder 001 very conveniently by setting the lifting mechanism, which greatly reduces the labor intensity of manpower. By setting the rotation mechanism to cooperate with the cleaning mechanism, it can Rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com