Aligning tool, aligning method, fiber inserting core assembly, and fiber connector

A fiber optic connector and fiber optic ferrule technology, which is applied in the coupling of optical waveguides, etc., can solve the problems of low multimode ferrule single-mode fiber optic connector ferrule, high cost of single-mode connectors, and high requirements for related dimensions. , to achieve the effects of low cost, improved performance, random intermatability, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings. In the specification, the same or similar reference numerals designate the same or similar components. The following description of the embodiments of the present invention with reference to the accompanying drawings is intended to explain the general inventive concept of the present invention, but should not be construed as a limitation of the present invention.

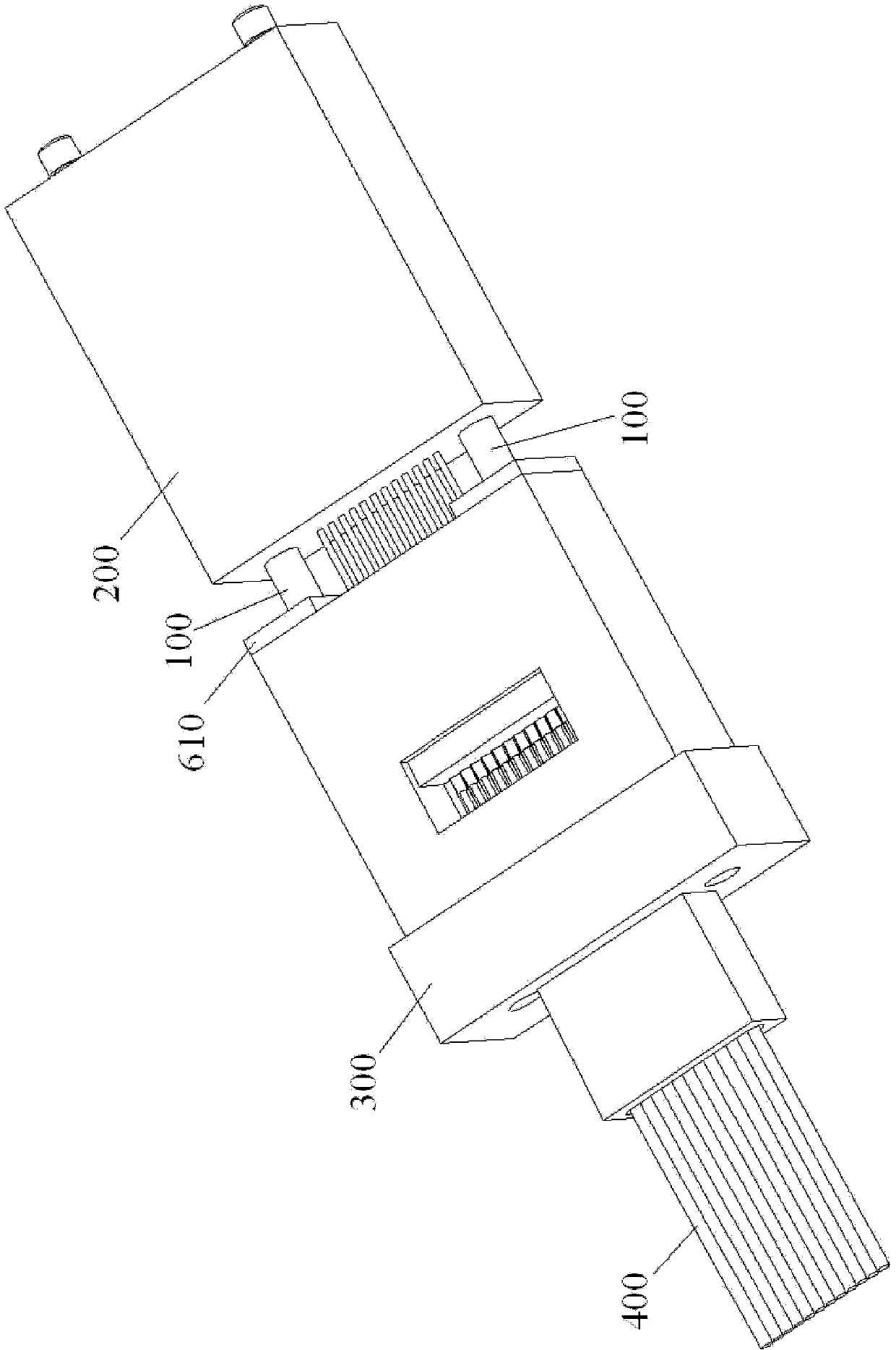

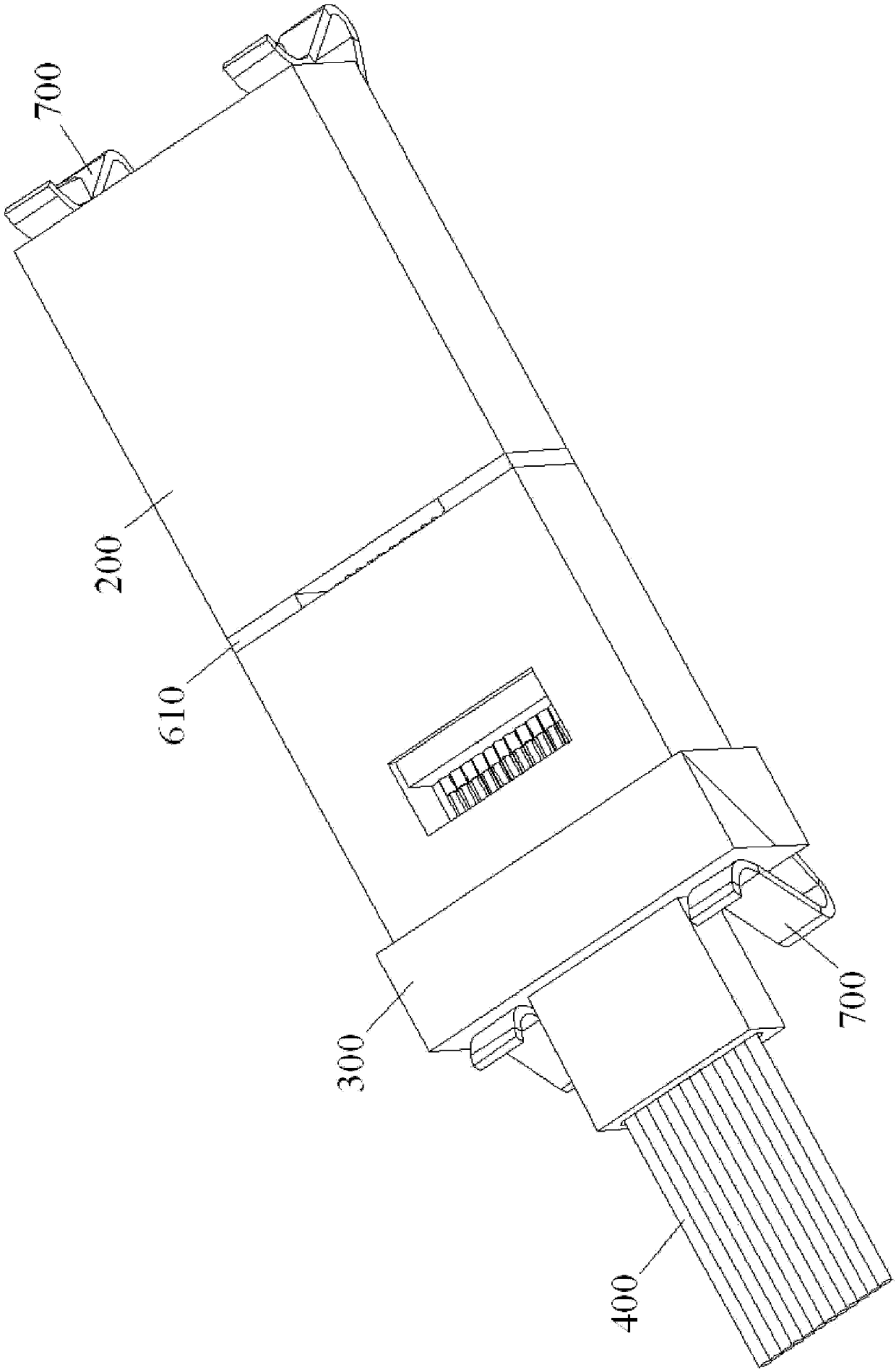

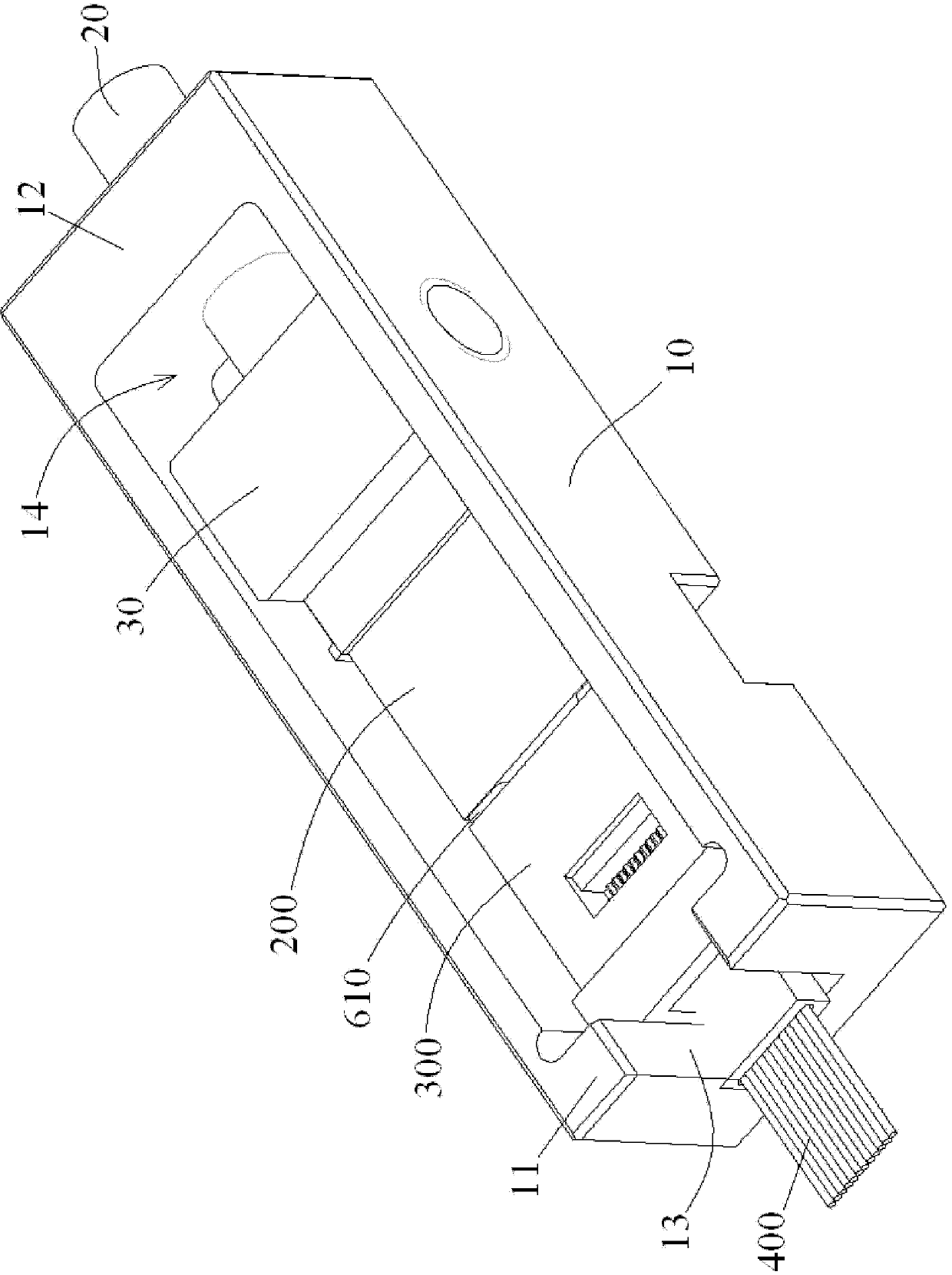

[0080] figure 1 It is a schematic diagram of an alignment tool for manufacturing a holey fiber ferrule 300 according to the first exemplary embodiment of the present invention. figure 2 for figure 1 Schematic of the alignment tool shown, showing the alignment tool's clamps and spacing controls. image 3 for figure 1 and figure 2 A perspective schematic of the alignment tool shown in .

[0081] like figure 1 , figure 2 and image 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com