Liquid-solid two-way coupling real-time simulation test bench for tank vehicles

A real-time simulation and two-way coupling technology, which is applied in vehicle testing, mechanical component testing, machine/structural component testing, etc. Complexity and other problems, to avoid the calculation speed is too slow, reduce development costs and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

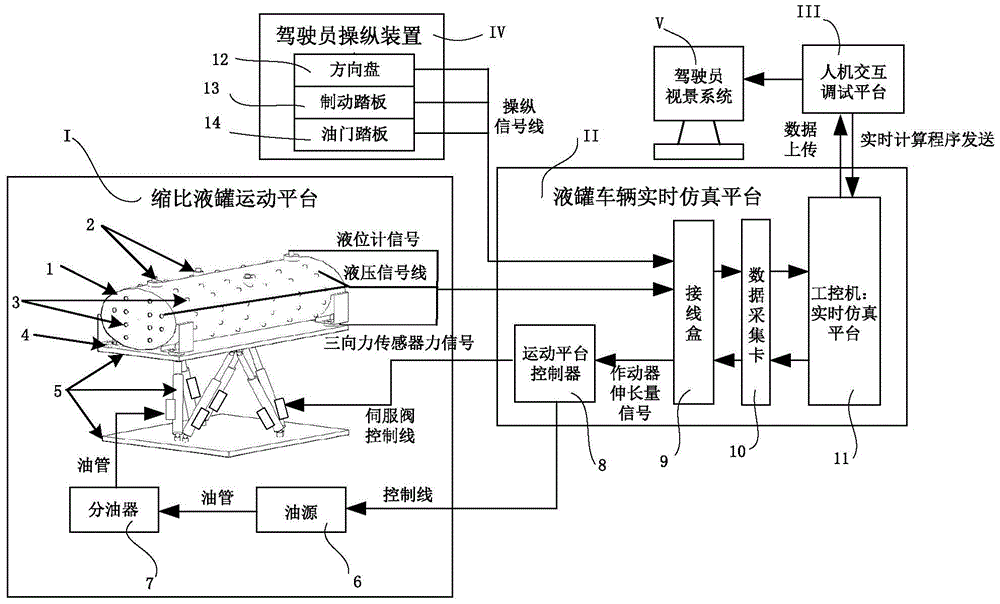

[0045] refer to figure 1 The liquid-solid two-way coupling real-time simulation test bench for liquid tank vehicles according to the present invention includes a scaled liquid tank motion platform assembly I, a liquid tank vehicle real-time simulation platform II, a human-computer interaction debugging platform III, a driver control device IV and Driver Vision System V.

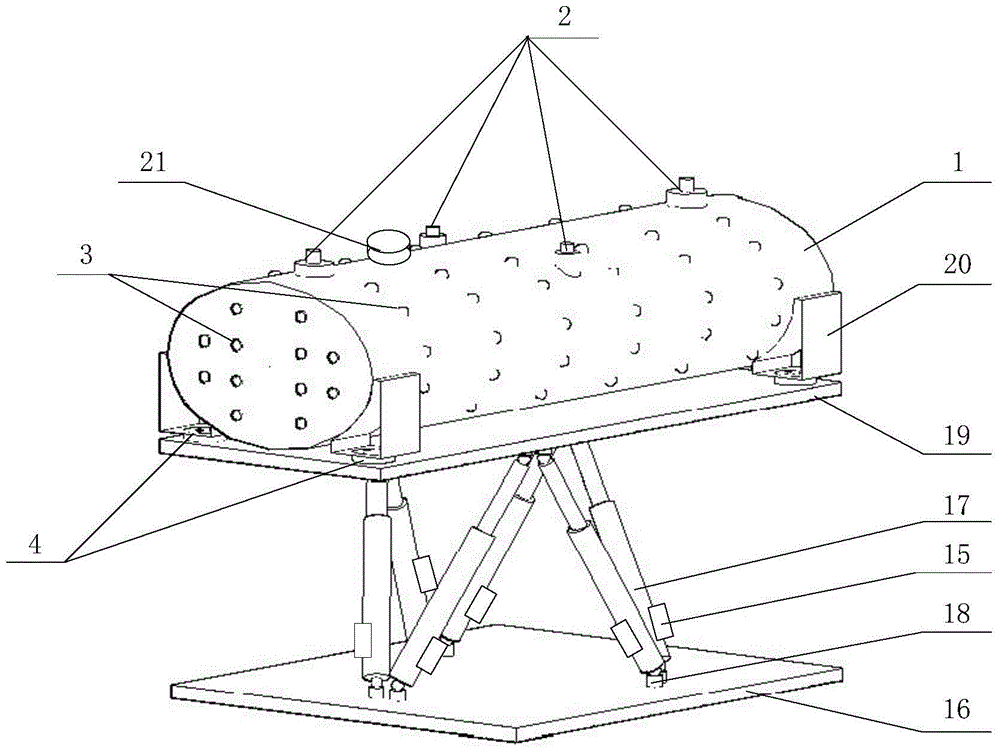

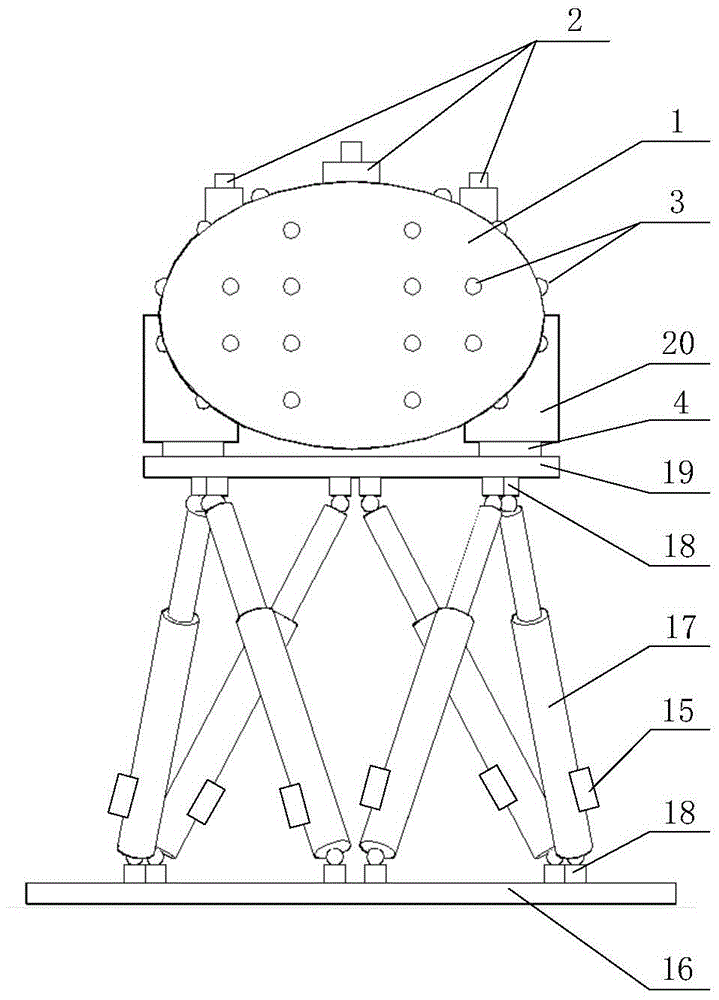

[0046] The scaled liquid tank motion platform assembly I includes a scaled liquid tank 1, a liquid level gauge 2 installed inside the liquid tank, a liquid pressure sensor 3, four three-way force sensors 4 and a six-degree-of-freedom motion platform assembly, six degrees of freedom The six-degree-of-freedom motion platform assembly includes a six-degree-of-freedom motion platform 5, an oil source 6 for providing oil for the six-degree-of-freedom motion platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com