Charging method for hybrid electric bus super capacitors

A super capacitor and hybrid technology, applied in electric vehicles, battery circuit devices, current collectors, etc., can solve the problems of factory charging and power supply of super capacitors, achieve a simple charging process, and solve the problem of factory charging and power supply after maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

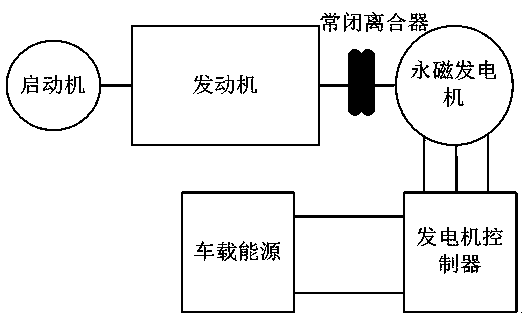

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] The steps of the charging method for hybrid electric passenger car supercapacitor of the present invention are as follows:

[0016] (1) Power-limited charging: The generator carried by the hybrid electric bus itself charges the supercapacitor. First, the starter is controlled by the whole vehicle to start. During the process of increasing the speed of the starter, the power generated by the starter drives the rotation of the engine shaft. The generator works, and the counter electromotive force generated by the generator charges the supercapacitor;

[0017] (2) Low-power charging: When the supercapacitor voltage reaches the first set value, the engine starts to drive the generator to charge the supercapacitor with low power;

[0018] (3) Trickle charging: When the low-power charging makes the supercapacitor voltage reach the second set value, the gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com