Modular type fusion-and-fission hybrid reactor cladding fuel section based on Z pinch driving

A fuel area and modular technology, applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve problems such as poor engineering realization, complex coolant flow channels, and large number of modules, and achieve effective cooling and good energy amplification. , to overcome the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

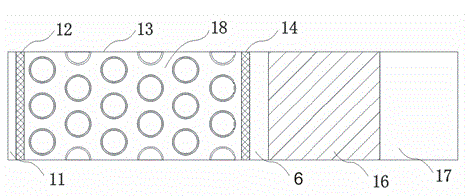

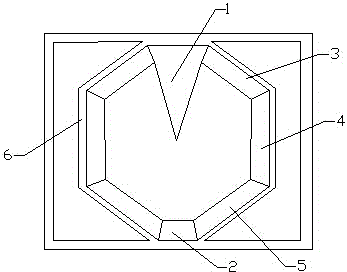

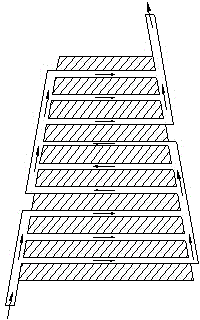

[0042] Example 1, such as image 3 , Figure 4 , Figure 5 Shown:

[0043] Said N=20, and the annular occupation angle of each fuel block is 18 degrees.

[0044] in:

[0045] The width of the middle module 4 is 2.468 m, and the height is 6.92 m; the number of pipes in each layer of the middle module 4 is 94, a total of 564 pipes; the total flow channel area is 0.1295m 2 ; Power 75.41 MW; Coolant flow rate 306.9 kg / s; Coolant flow rate 3.365 m / s.

[0046] The upper end module 3 has a top width of 0.53 m, a bottom end width of 2.468 m, and a height of 6.92 m; each row of upper end modules 3 has 263 pieces, a total of 1578 pieces; the height direction is divided into 3 groups, each group has 526 pipes, and the total flow channel The area is 0.1208m 2 ; Power 45.63 MW; Coolant flow rate 185.7 kg / s; Coolant flow rate 2.183 m / s.

[0047] The lower end module 5 has a bottom width of 0.53 m, a top width of 2.468 m, and a height of 6.92 m; each row of lower end modules 5 has 263...

Embodiment 2

[0051] Said N=24, the circular occupation angle of each fuel block is 15 degrees.

[0052] in:

[0053] The width of the middle module 4 is 1.843 m, and the height is 6.92 m; the number of pipes in each layer of the middle module 4 is 61, a total of 305 pipes; the total flow channel area is 0.0958 m 2 ; Power 53.56 MW; Coolant flow rate 242.2 kg / s; Coolant flow rate 3.590 m / s.

[0054] The upper end module 3 has a top width of 0.39 m, a bottom end width of 1.843 m, and a height of 6.92 m; the upper end module 3 has 230 pieces in each row, a total of 1150 pieces; the height direction is divided into 5 groups, each group has 230 pipes, and the total flow channel The area is 0.0723 m 2 ; Power 32.45 MW; Coolant flow rate 146.8 kg / s; Coolant flow rate 2.885 m / s.

[0055] The lower end module 5 has a bottom width of 0.39 m, a top width of 1.843 m, and a height of 6.92 m; the lower end modules 5 have 230 pieces in each row, a total of 1150 pieces; the height direction is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com