A thermal recovery method of carbonate heavy oil reservoir and its application

A technology for heavy oil reservoirs and carbonate rocks, which is applied in the development of fluids, earth-moving drilling, wellbore/well components, etc. The effect of wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

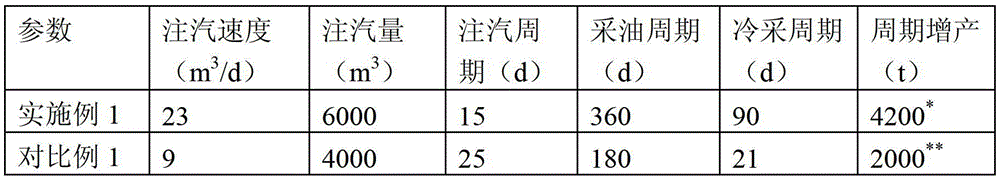

Embodiment 1

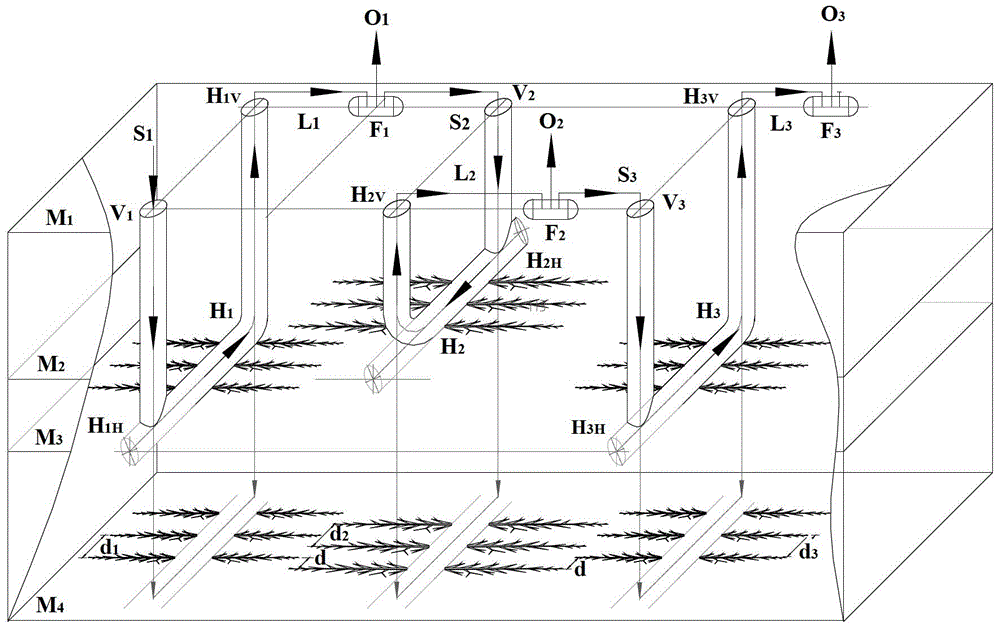

[0069] Step 1: Select Implementation Blocks

[0070] (1) Geological conditions of the selected block: the average depth of the reservoir is 1420m, the permeability is less than 100md, the reservoir has good oil content, the average viscosity of crude oil is 2000mps (50°C), that is, the thickness of the oil layer is greater than 65m, and the interlayer is not developed. The oil saturation is greater than 60%, the drilling rate of the oil layer is greater than 90%, the back pressure of the formation exceeds the rated pressure of the ground steam injection boiler, and the steam injection rate is lower than the predetermined minimum steam injection rate.

[0071] (2) The degree of reservoir control is high, open hole completion, the length of the horizontal section is greater than or equal to 400m.

[0072] (3) There are no large connecting fractures in the reservoir, and the surrounding water sources are sufficient.

[0073] Step 2: Fabric the Well

[0074] Three horizontal wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com