PET matte aluminium laminated film

A technology of aluminized film and matte film, which is applied in the field of packaging materials and can solve the problems of non-printable and non-matte

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

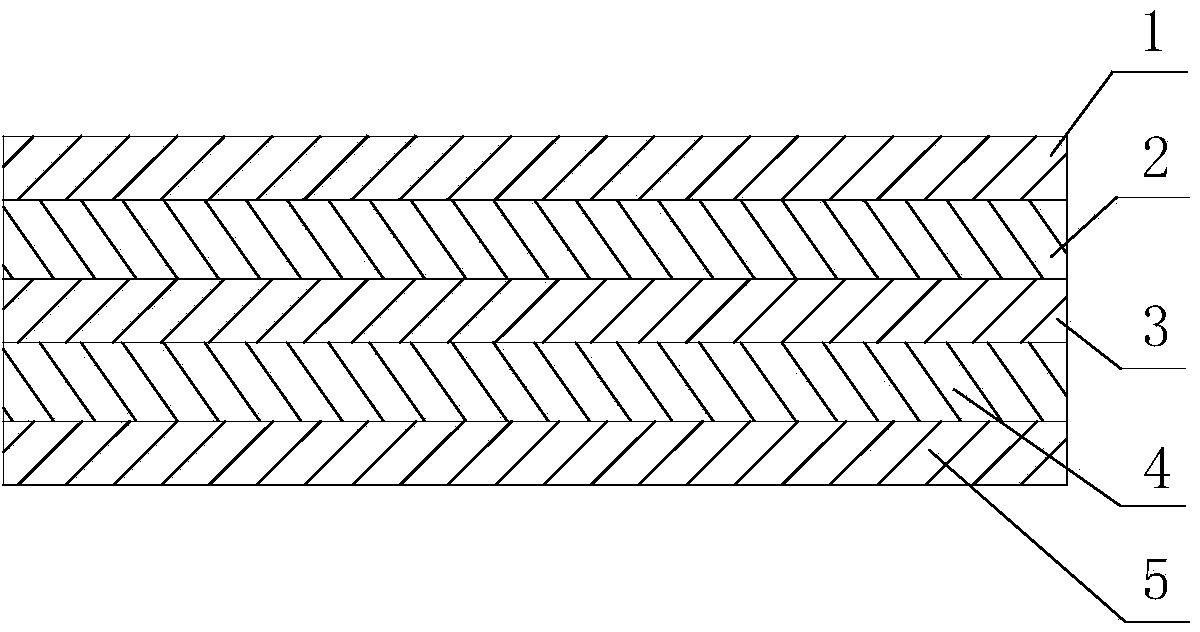

[0010] Such as figure 1 As shown, PET matte aluminized film, it includes UV printable coating 1, PET matte film 2, aluminum layer 3, network adhesive (reticulated glue) layer 4, backing paper 5, the bottom of PET matte film is plated (vacuum plating) has an aluminum layer, and the thickness of the aluminum layer is 300 to 400 angstroms; the underside of the aluminum layer is bonded by the network glue (anilox glue) layer 4 and the backing paper (transfer) 5; the top of the PET matte film is coated with UV printable coating. The material of the UV printable coating is acrylic.

[0011] The preparation of the above-mentioned PET matte aluminized film: the bottom of the PET matte film is plated (vacuum plated) with an aluminum layer, and the bottom of the aluminum layer is bonded with the base paper 5 by the network glue (reticulated glue) layer 4, and then coated with the PET matte film. The top of the film is coated with a UV printable coating to obtain a PET matte aluminized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com