Engine

A technology of engine and turbine sensors, which is applied in the direction of combustion engine, engine control, engine components, etc., to achieve the effect of effective malfunction and reduction of computing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

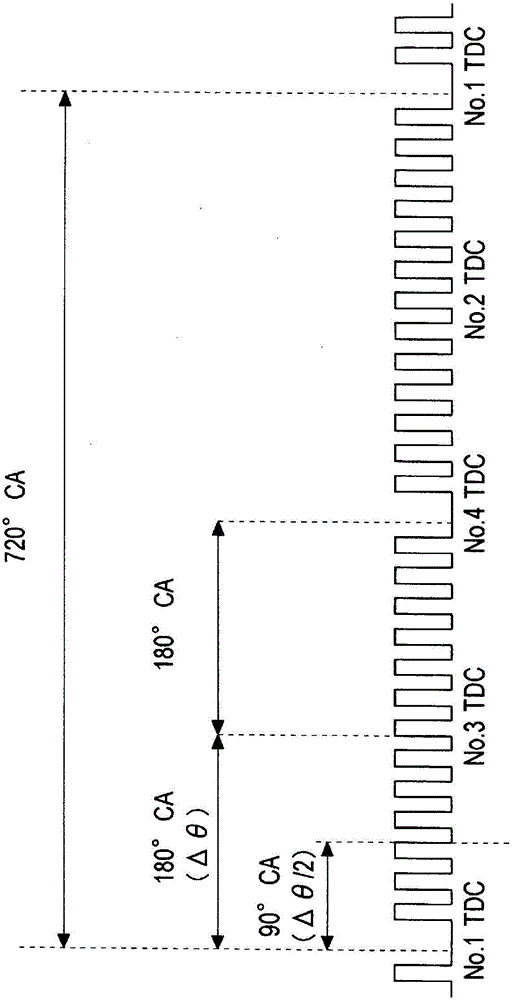

[0029] Next, preferred embodiments of the engine according to the present invention will be described with reference to the drawings.

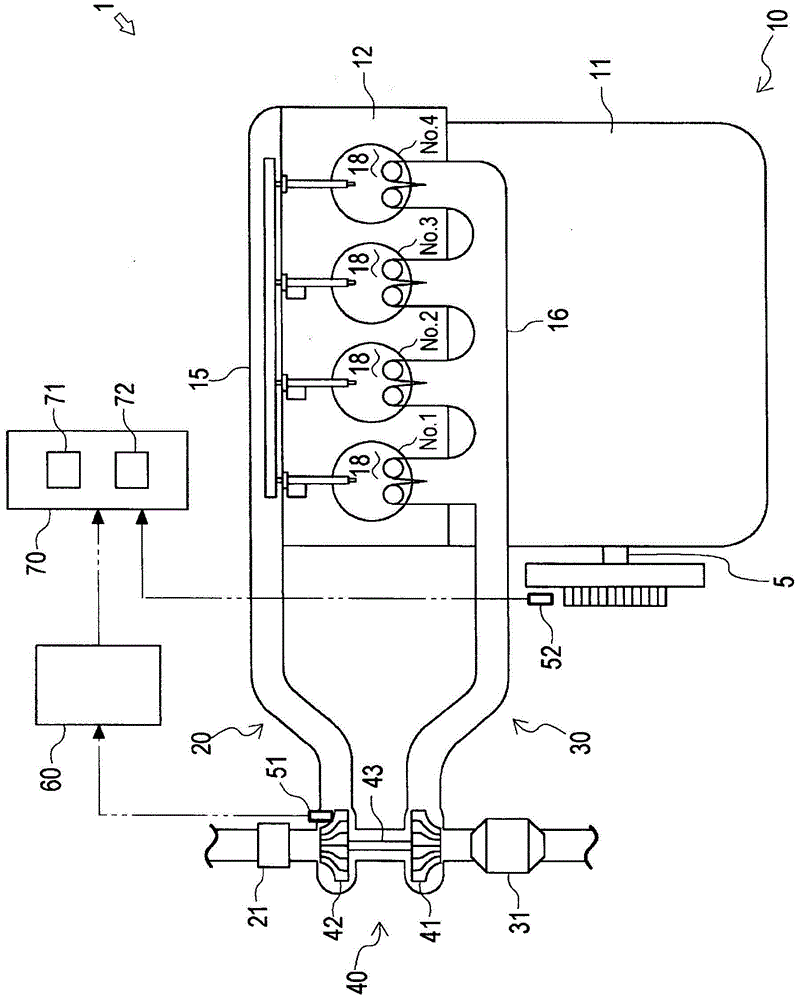

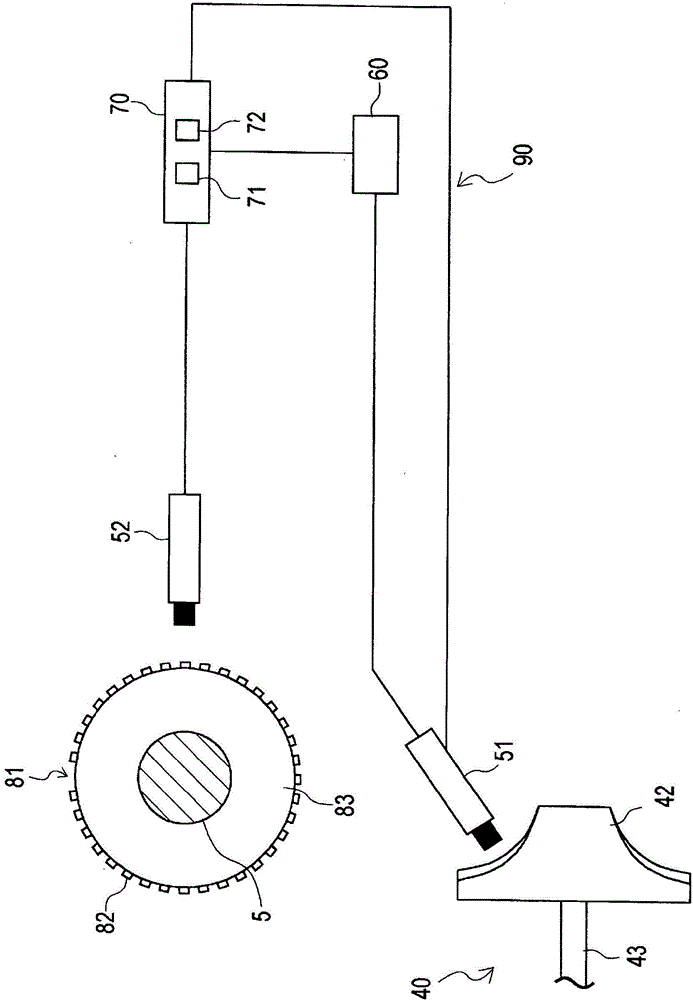

[0030] exist figure 1 In , the schematic structure of the engine 1 according to this embodiment is shown. exist figure 2 In FIG. 2 , schematic configurations of the turbine sensor 51 and the crank angle sensor 52 in the aforementioned engine 1 are shown.

[0031] Such as figure 1 and figure 2 As shown, the aforementioned engine 1 is equipped with: an engine body 10, the engine body 10 has a plurality of cylinders No.1, No.2, No.3, No.4; an intake pipeline 20, the intake pipeline 20 will Intake air is guided into the combustion chamber 18 of the aforementioned engine body 10; an exhaust line 30, which becomes a passage of exhaust gas discharged from the aforementioned combustion chamber 18; a supercharger 40, the supercharger 40 There is a turbine 41 inserted into the aforementioned exhaust pipeline 30 and a compressor 42 inserted into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com