Hydraulic anchor rod group drilling machine

A technology for drilling rigs and anchor rods, which is applied in the direction of installing anchor rods, drill pipes, and drill pipes. Effect of Pore Efficiency Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

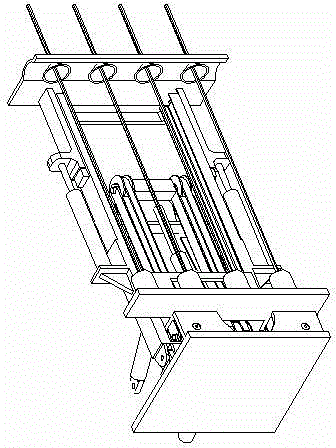

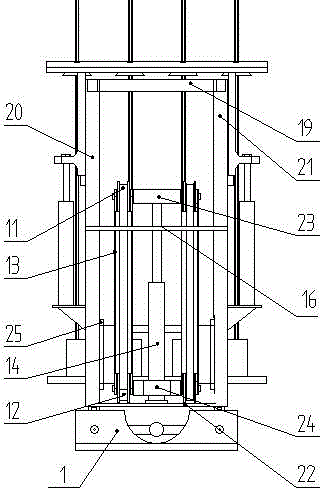

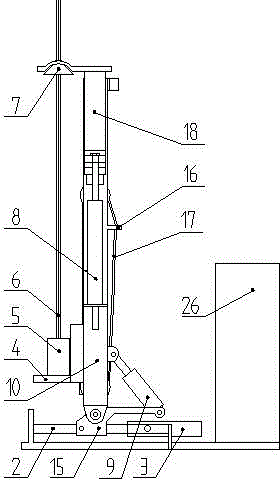

[0020] like figure 1 , 2 , 3, a hydraulic rock bolt group drilling rig, including a horizontal movement mechanism, an inclination adjustment mechanism, a drilling rig part and a drilling mold part,

[0021] The structure of the horizontal movement mechanism: the base 1 is equipped with a horizontal movement guide rail 2, the horizontal movement slider 15 is installed on the horizontal movement guide rail 2, one end of the horizontal movement oil cylinder 3 is connected with the horizontal movement slider 15, and the other end is connected with the base 1, The base 1 is connected with the tunneling machine 26;

[0022] The structure of the tilt adjustment mechanism: the two ends of the tilt adjustment cylinder 9 are respectively hinged with the cantilever end of the drilling rig frame 10 and the horizontally moving slider 15;

[0023] The structure of the drilling rig part: the drilling rig frame 10 is connected by the upper beam 19, the chain fixing frame 16, and the lower b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com