A fully automatic pagoda paper tube machine

A paper tube machine, fully automatic technology, applied in the field of paper tube machines, can solve the problems that paper and tube cones cannot be well fitted, the paper tube and tube cones are not easily separated, and the paper conveying position is inaccurate, etc. Achieve the effect of improving clarity, high degree of automation, and fast paper feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

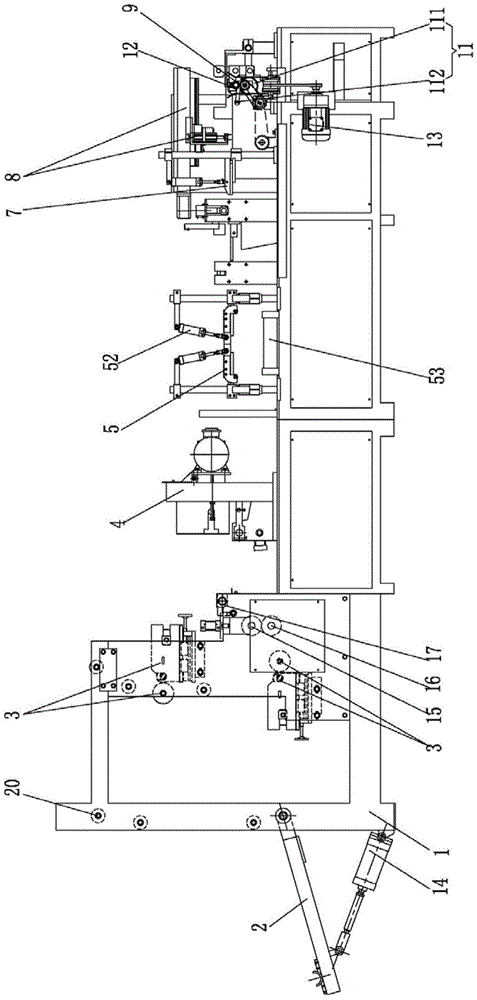

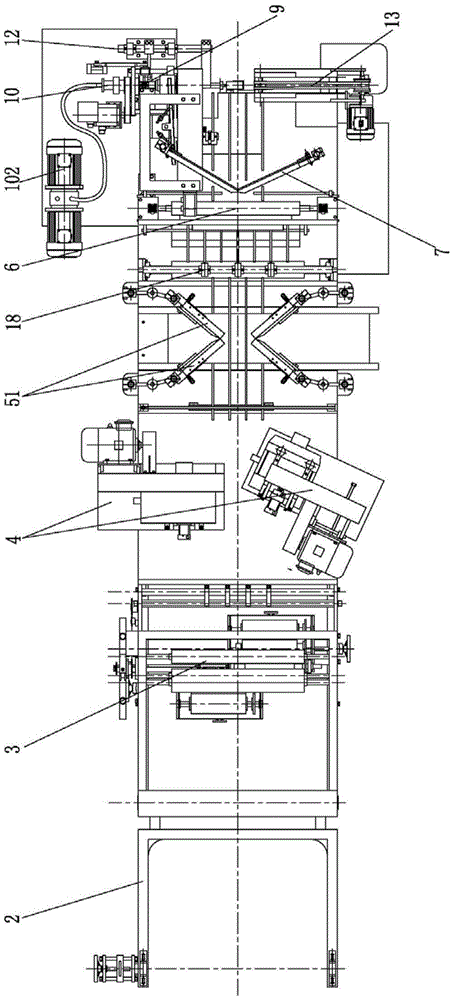

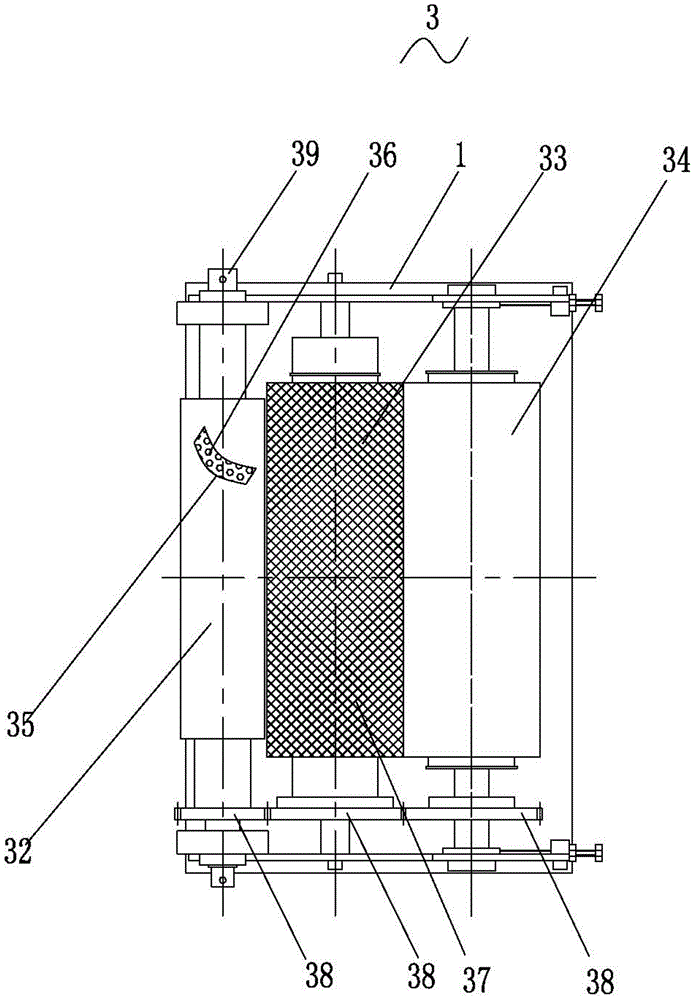

[0035] Please refer to the attached figure 1 to attach Figure 8 As shown, the present invention is a kind of full-automatic pagoda paper tube machine, and it is made up of frame 1, base paper elevating frame 2, paper printing device 3, napping device 4, initial cutting device 5, gluing device 6, forming cutter device 7. It consists of linear paper feeding and needle removal device 8, tube rolling device 9, tube blowing and suction control device 10, port cutter device 11, paper tube pressing device 12, and tube feeding device 13.

[0036] Wherein, the blank paper lifting frame 2 is pivotally connected to one end of the frame 1, and a roll of blank paper can be installed on the blank paper lifting frame 2. A paper lifting cylinder 14 is provided at the bottom of the blank paper elevating frame 2, so as to facilitate the installation of the blank paper.

[0037] The paper printing device 3, the napping device 4, the preliminary cutting device 5, the gluing device 6, the formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com