Steel rail nondestructive reinforcing equipment

A technology for steel rails and equipment, applied in the field of non-destructive reinforcement equipment for elastic clip-type boltless steel rails, can solve the problems of increased maintenance and repair workload, difficult to find, unstable clamping force, etc. The effect of crack propagation and fracture, avoidance of additional damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

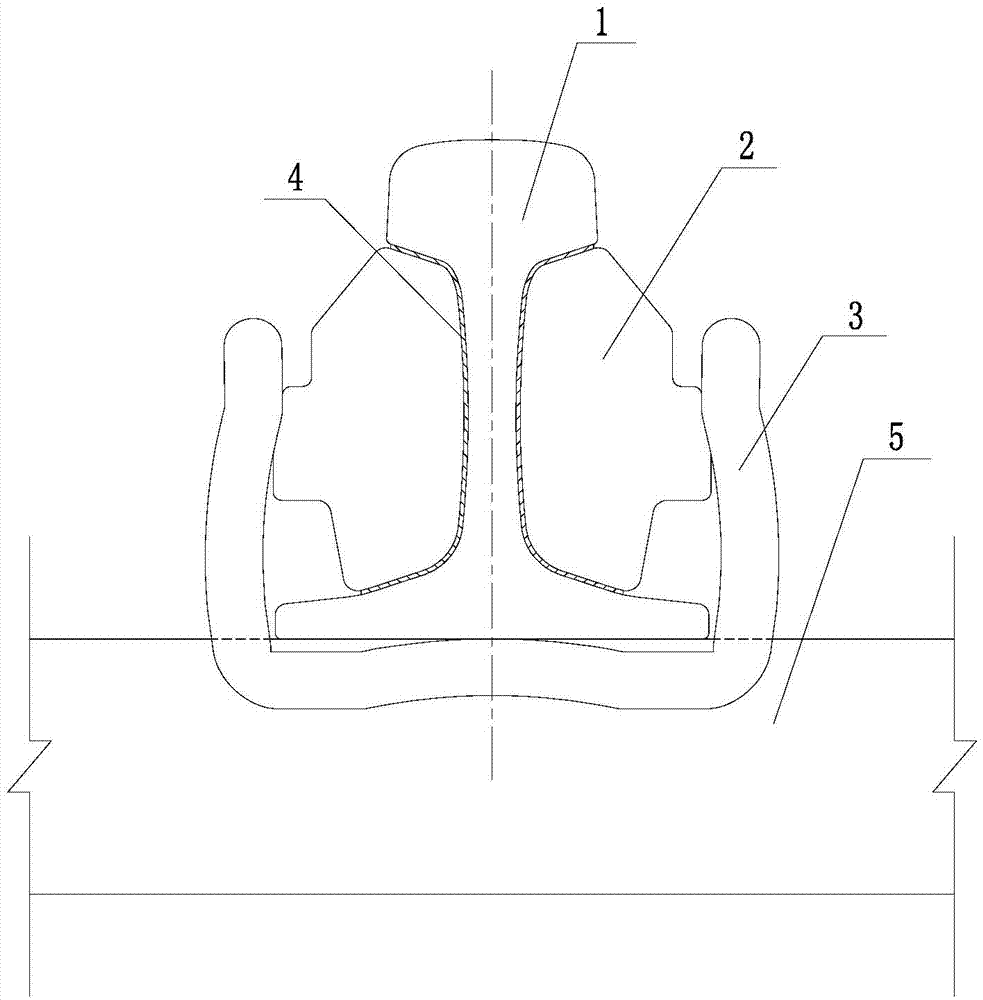

[0030] Such as figure 1 As shown, the rail non-destructive reinforcement equipment of the present invention includes an elastic clip 3, a splint 2 and a high-strength adhesive 4 that are bent integrally; The geometric shape of the abdomen, lower jaw and top surface of the rail bottom, the geometric shape of the splint 2 can be adjusted according to the shape of the rail, and it is suitable for the reinforcement of different types of rails such as 50, 60, and 75kg / m; the inner and upper sides of the splint 2 and the lower side are bonded to the abdomen, lower jaw and top surface of the rail bottom of the rail 1 through a high-strength adhesive 4, forming an integral body with the rail, increasing the working cross-sectional area of the rail, effectively reducing the dynamic bending stress of the rail under the train load, and preventing The cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com