Method for Determination of Niobium Content in Iron and Steel by Separation of Chlorosulfophenol S by Beryllium Hydroxide

A technology of chlorosulfonol and beryllium hydroxide, which is applied in the direction of color/spectral characteristic measurement, analysis through chemical reaction of materials, material analysis through observation of the influence on chemical indicators, etc., which can solve the problem of long separation steps, Complicated operation, poor masking effect and poor stability of the method to achieve high stability, fast detection speed and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

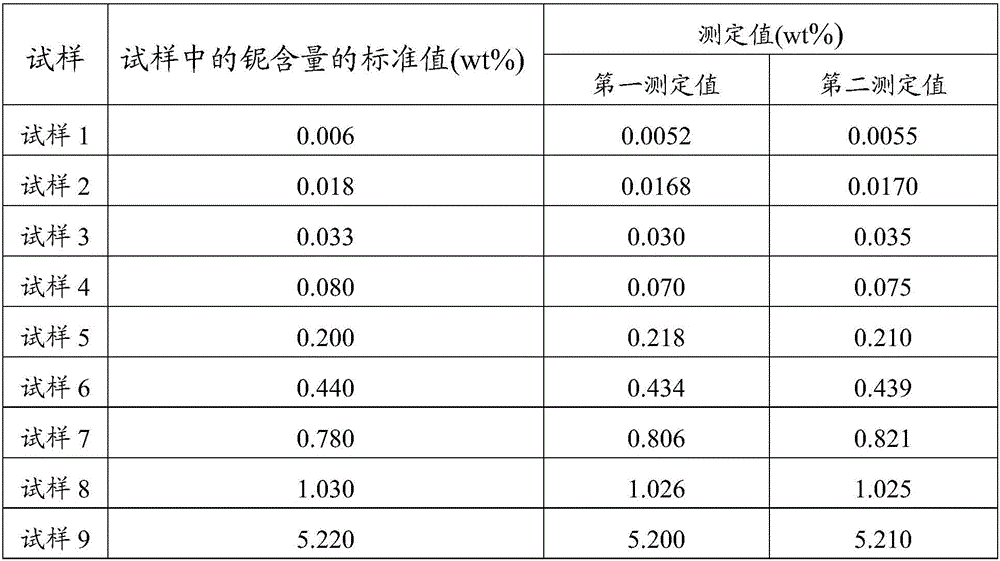

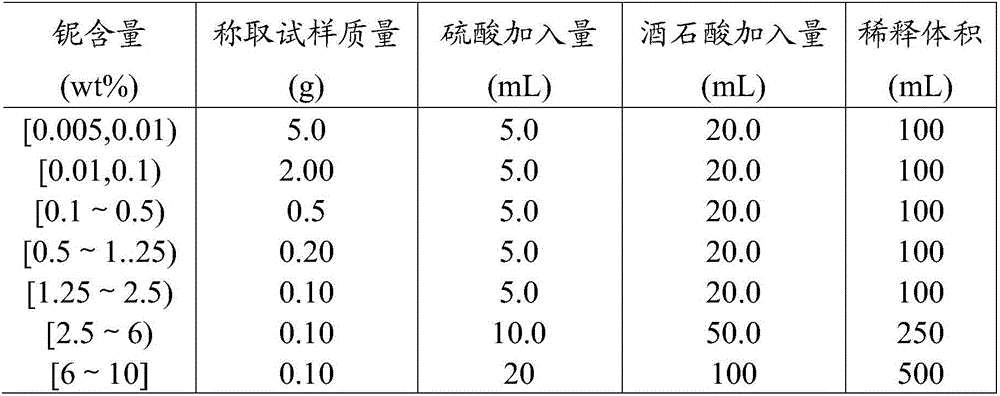

[0018] The present invention aims at the problems of long measurement time, poor measurement stability, poor measurement accuracy and narrow measurement range existing in the method for determining the content of niobium in iron and steel in the prior art, and provides a method that can measure the content of niobium in the range of 0.005wt% to 10wt A method for the determination of niobium content in iron and steel by separation of beryllium hydroxide in the range of chlorosulfonol S spectrophotometry. The method has high determination stability, fast determination speed and high determination accuracy and precision.

[0019] The present invention dissolves the sample with acid, uses perchloric acid to fume to remove the residual acid of the dissolved sample in the solution and oxidizes chromium to positive hexavalent, and uses ethylenediaminetetraacetic acid disodium diammonium solution and / or ethylenediamine Tetraammonium tetraacetate solution to mask iron, nickel, copper, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com