Filter device and backwashing method of filter materials

A filter device and filter material technology, applied in the direction of loose filter material filter, filtration separation, separation method, etc., can solve the problems of inability to obtain backwashing effect, a large amount of backwashing water, unchanged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

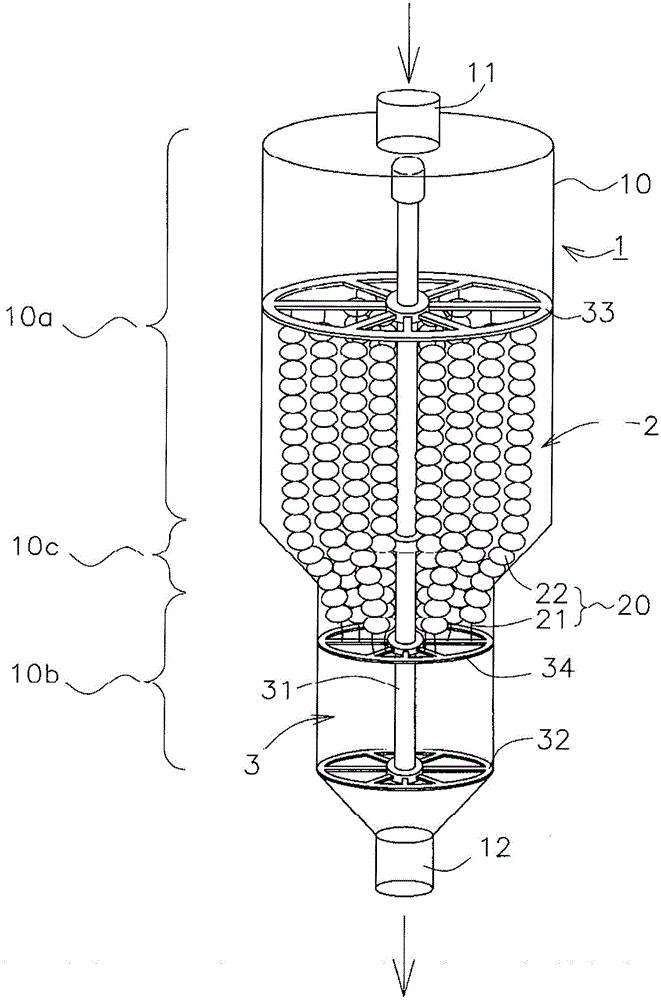

[0034] figure 1 It is a schematic diagram which shows 1st Embodiment of a filter apparatus. This embodiment is as figure 1 As shown, the filter medium 2 is accommodated in the inside of the cylindrical case 1, and it is comprised. The casing 1 is provided with an inflow portion 11 for inflowing raw water and a discharge portion 12 for discharging filtered treated water, and a storage portion 10 for accommodating the filter medium 2 is formed between the inflow portion 11 and the discharge portion 12. . Raw water flows in through a pump not shown, and is supplied from the inflow part 11 with an appropriate pressure applied thereto. Then, after the suspended solids in the storage part 10 are captured by the filter medium 2, they are discharged from the discharge part 12, and the raw water is transported from the inflow part 11 (upper in the figure) to the discharge part 12 (lower in the figure).

[0035] The filter medium 2 accommodated inside the casing 1 is supported by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com