Mechanism for detecting whether product mounting is qualified or not

A product and qualified technology, applied in the field of institutions that detect whether the product is installed qualified, can solve problems such as no blocking function, high labor intensity, and installation of unqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

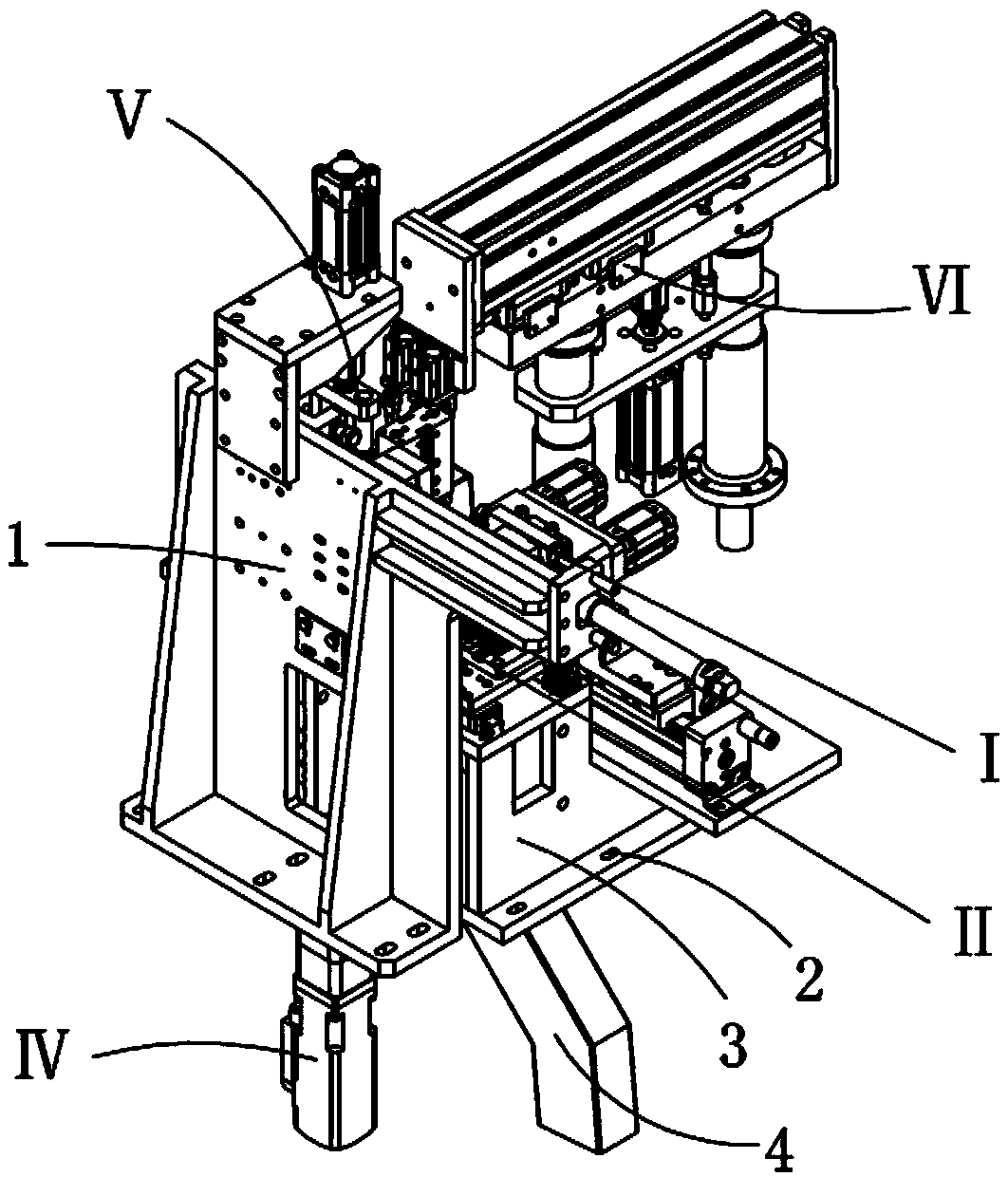

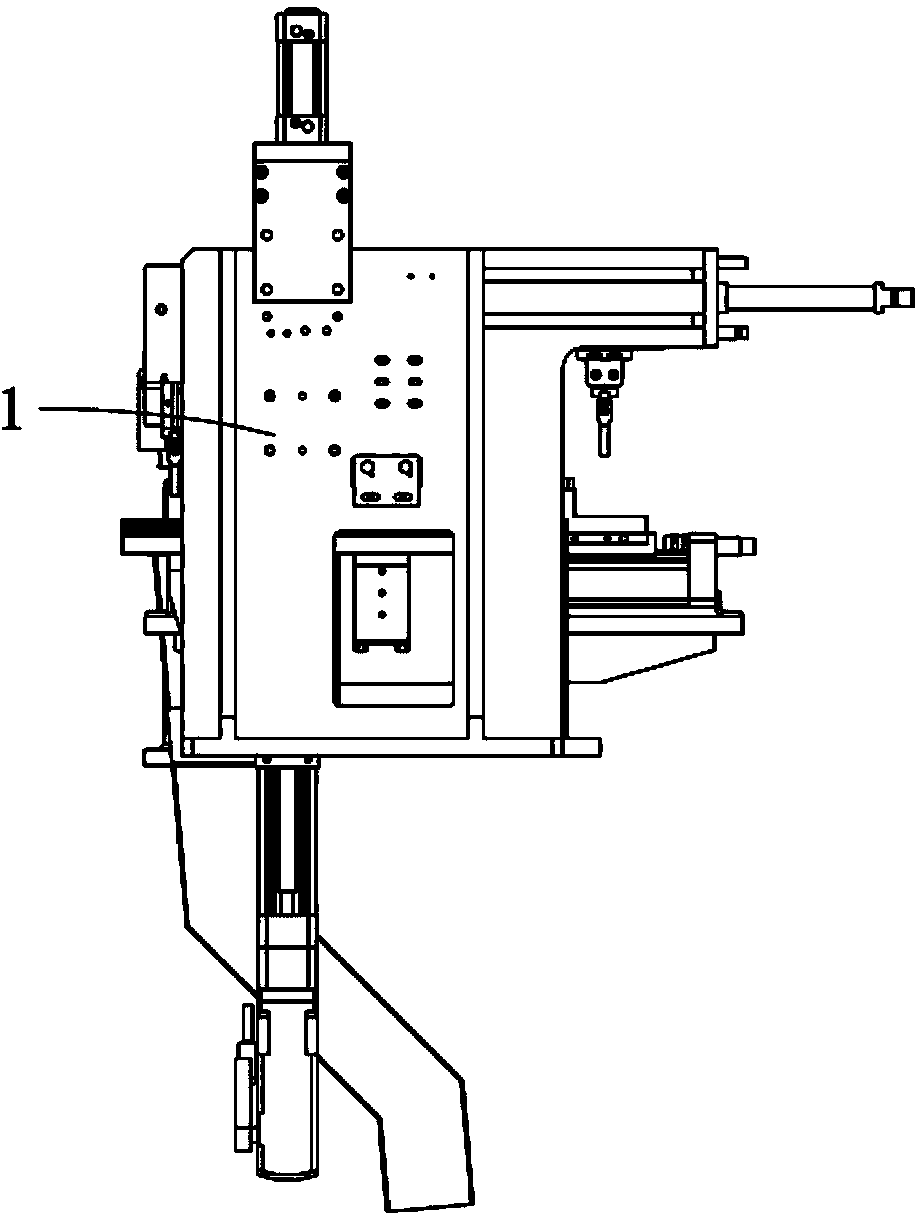

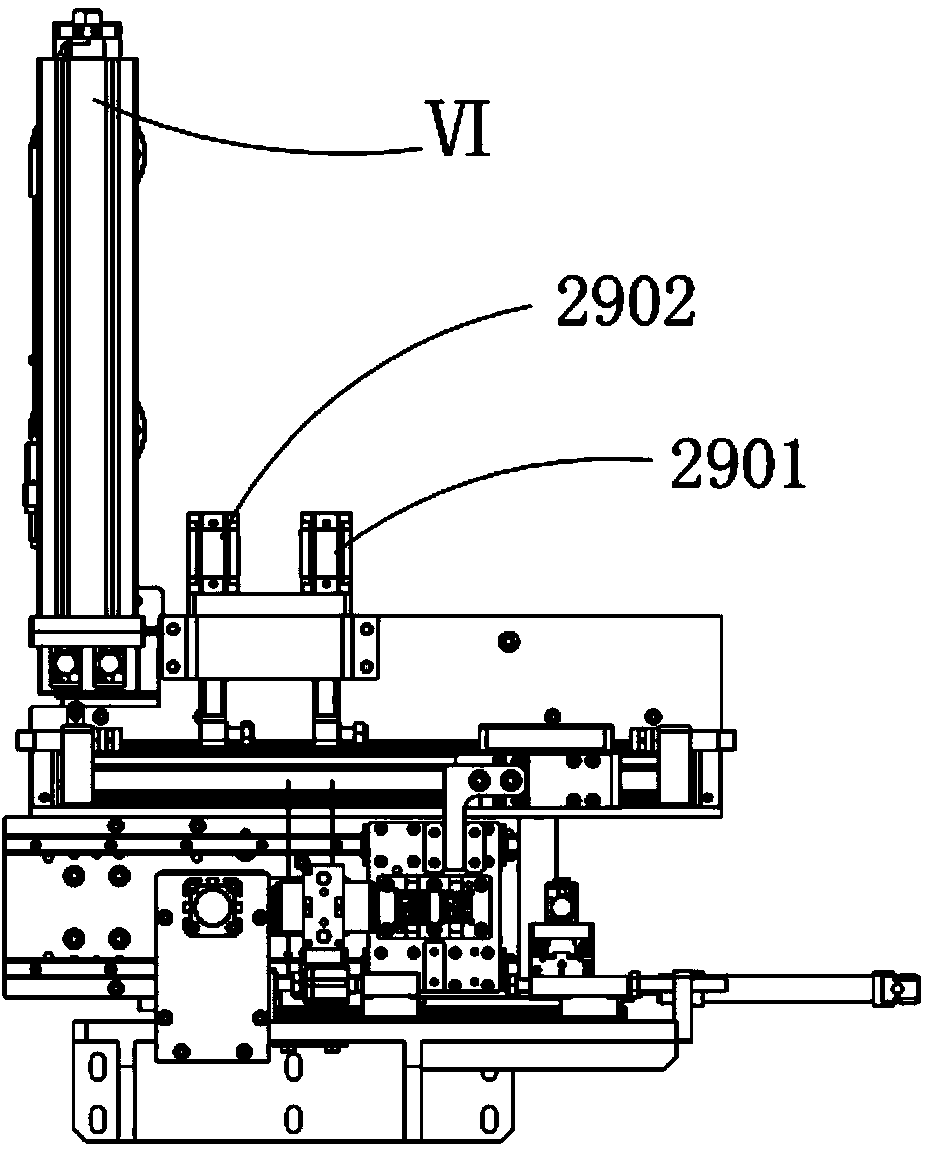

[0039] Examples, see attached Figure 1-10 , a mechanism for detecting whether the product is qualified for installation, which includes a mounting frame 1, a grabbing mechanism Ⅰ, a base 2, a support plate 3, a recovery channel 4, a vehicle transportation mechanism Ⅱ, a calibration mechanism Ⅲ, a thrust detection mechanism Ⅳ, a push-down mechanism Mechanism V and unqualified product removal mechanism VI, the grabbing mechanism is installed on the installation frame, two support plates are installed on the base, the carrier transport mechanism is installed on the two support plates, and the recovery channel is installed on the base left side. The bottom plane of the base is flush with the bottom plane of the installation frame, and the base and the installation frame are respectively fixed on a fixed base plate or other mechanisms to facilitate the fixing of the entire mechanism.

[0040] The grasping mechanism includes a grasping cylinder fixing plate 5, a grasping cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com