Suspended No-Resonance Isolators

A non-resonance, suspension technology, used in shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as resonance, achieve good vibration isolation effect, and the effect of adjustable pre-compression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

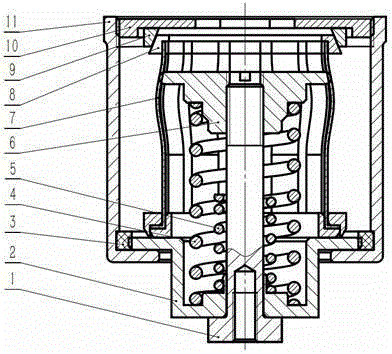

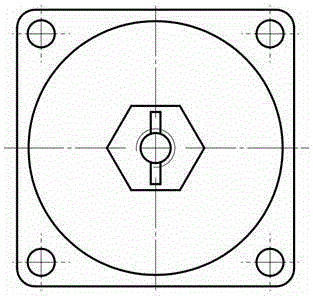

[0015] Such as figure 1 , as shown in 2, a suspension-type non-resonant vibration isolator, including a suspension core 1, a lower spring seat 2, a wire mesh 3, a main spring 4, a bottom spring 5, an upper spring seat 6, and a drum-shaped leaf spring damper 7 , Opening tapered collar 8, upper tapered collar 9, base 10, shell 11.

[0016] The lower end of the suspension core 1 has an internally threaded hole. The suspension device is connected with the lower spring seat 2 by sliding fit, and is threaded with the upper spring seat 6. The main spring 4 and the bottom spring 5 are embedded in the upper and lower spring seats 6 and 2. The bottom spring 5 is set on the suspension core 1, the main spring 4 is sleeved outside the bottom spring 5, the upper spring seat 6 is dry frictionally connected with the waist drum-shaped spring plate damper 7, the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com