Preparation method and application of quaternary ammonium epoxy siloxane particles

The technology of epoxy siloxane and propyl trimethoxy silane is applied in the field of preparation of quaternary ammonium epoxy siloxane particles, which can solve problems such as blanks in research work and achieve the effect of preventing bacterial re-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

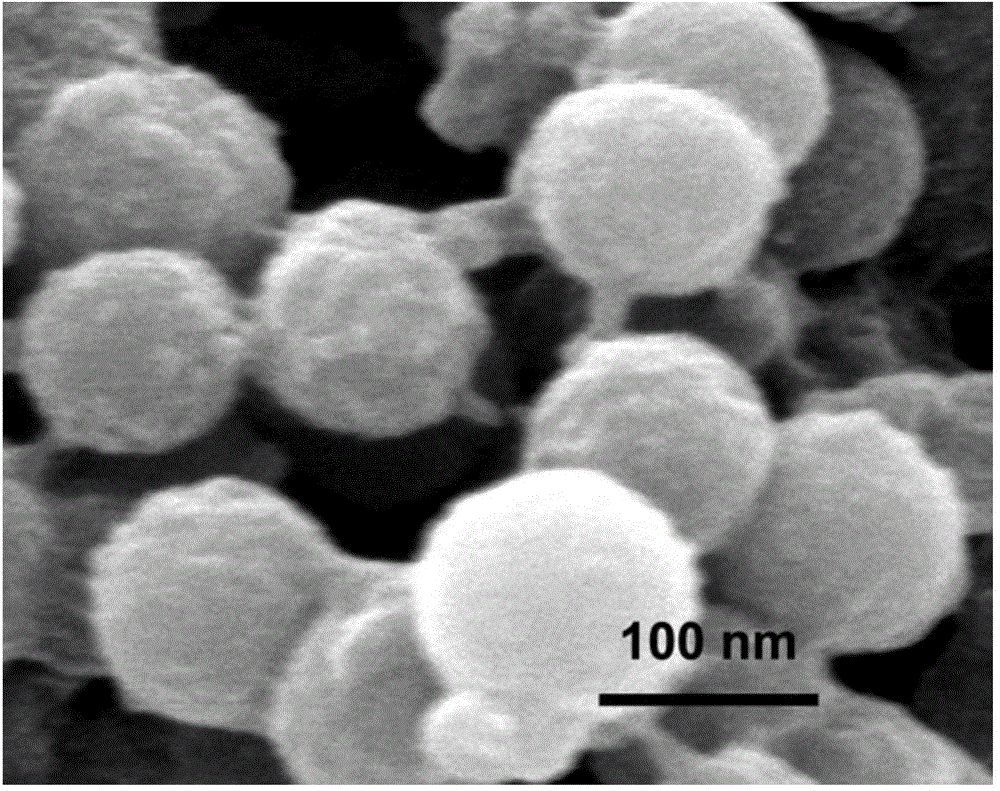

Image

Examples

Embodiment 1

[0032] A kind of preparation method of quaternary ammonium epoxy group siloxane particle, it comprises the following steps:

[0033] The reaction precursors are: tetraethylorthosilicate (TEOS), γ-glycidyl etheroxypropyltrimethoxysilane (3-GPTS), dimethyloctadecyl[3-(trimethoxysilane base) propyl] ammonium chloride (SiQAC).

[0034] 1) Mix TEOS, 3-GPTS and SiQAC according to the molar ratio of 9:1:1, take 5mL of the mixture and add it into a reaction vessel containing 40mL of ethanol (100%) and 100mL of ultrapure water, stir well, and then 0.7mL of hydrochloric acid (2M), stirred at 1200rpm with a magnetic rod for 1.5min;

[0035] 2) Add 1.4mL sodium hydroxide (2M) solution to the reaction vessel, and reduce the speed of the magnetic rod to 350rpm. Slowing down the stirring speed in this way is beneficial to control the uniformity of the particle size and diameter of the precipitated product, and the reaction is maintained for 2 hours;

[0036] 3) The solid precipitate obtain...

Embodiment 2

[0038] A kind of preparation method of quaternary ammonium epoxy group siloxane particle, it comprises the following steps:

[0039] 1) Mix TEOS, 3-GPTS and SiQAC according to the molar ratio of 12:2:1, take 10mL of the mixture and add it into a reaction vessel containing 80mL of ethanol (100%) and 160mL of ultrapure water, stir well, and then Add 1.2mL of hydrochloric acid (2M), and stir for 2min at a magnetic bar at 1200rpm;

[0040] 2) Add 2.5mL sodium hydroxide (2M) solution to the reaction vessel, and reduce the speed of the magnetic rod to 320rpm. Slowing down the stirring speed in this way is beneficial to control the uniformity of the particle size and diameter of the precipitated product, and the reaction is maintained for 2 hours;

[0041] 3) The solid precipitate obtained by the reaction is centrifuged to harvest the particle precipitate, which is repeatedly cleaned with ethanol, and then vacuum-dried to obtain the quaternary ammonium epoxy siloxane particle.

Embodiment 3

[0043] A kind of preparation method of quaternary ammonium epoxy group siloxane particle, it comprises the following steps:

[0044] 1) Mix TEOS, 3-GPTS and SiQAC according to the molar ratio of 15︰4︰1, take 10mL of the mixture and add it into a reaction vessel containing 100mL ethanol (100%) and 150mL ultrapure water, stir well, and then 1.5mL of hydrochloric acid (2M), stirred at a magnetic bar at 1200rpm for 2min;

[0045] 2) Add 3.0mL sodium hydroxide (2M) solution to the reaction vessel, and reduce the speed of the magnetic bar to 320rpm, so that the stirring speed is slowed down, which is beneficial to control the uniformity of the particle size and diameter of the precipitated product, and the reaction is maintained for 2 hours;

[0046] 3) The solid precipitate obtained by the reaction is centrifuged to harvest the particle precipitate, which is repeatedly cleaned with ethanol, and then vacuum-dried to obtain the quaternary ammonium epoxy siloxane particle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com