Sugarcane delivery roller

A technology for conveying rollers and sugarcane, which is applied in the field of rollers conveying sugarcane, can solve the problems of low production efficiency, short service life, jamming, etc., and achieve the effect of improving production efficiency and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

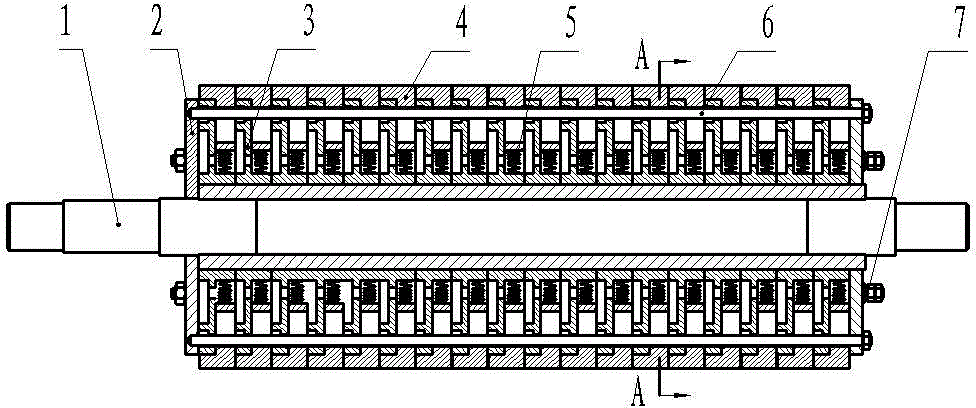

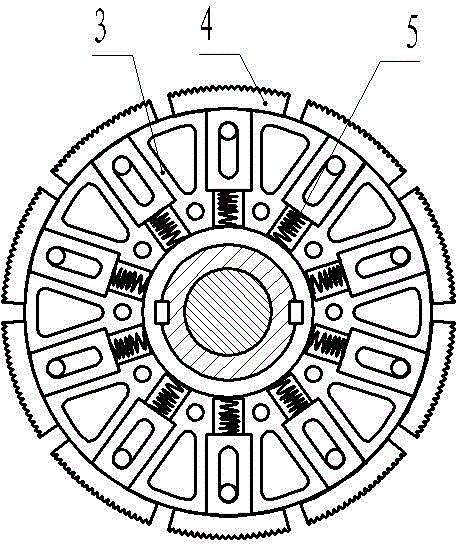

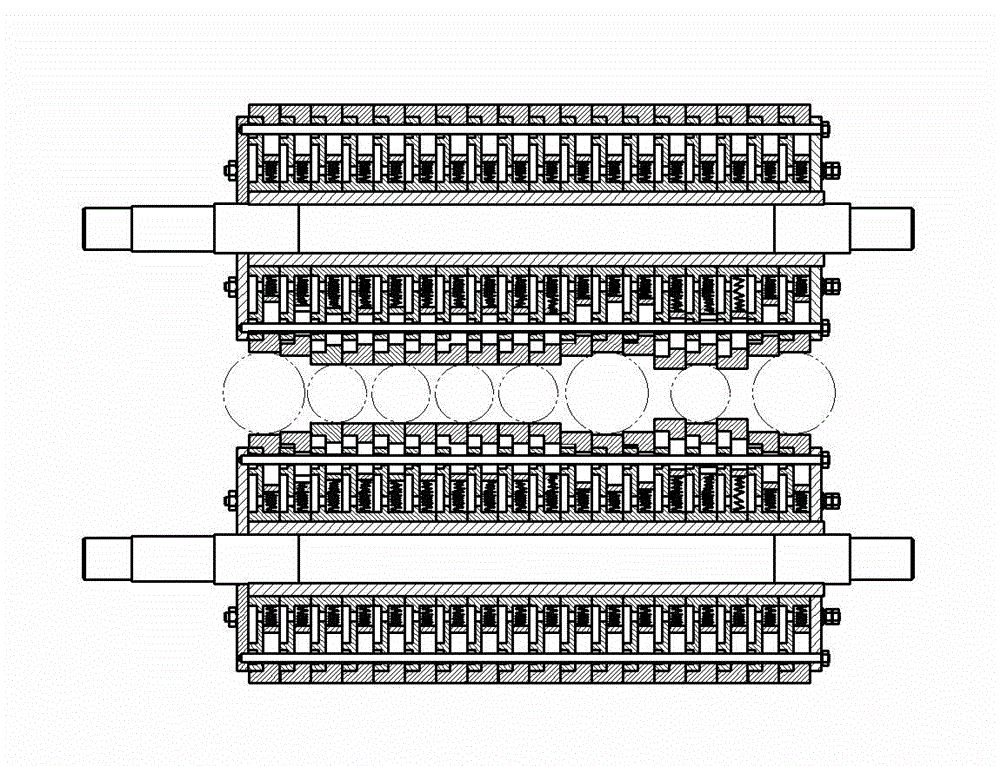

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing:

[0013] Such as figure 1 and figure 2 The shown sugarcane conveying roller includes a mandrel 1 and a plurality of conveying discs 3 that are sleeved on the mandrel 1, and eighteen conveying discs 3 are set on the mandrel 1 of the present embodiment, and each conveying disc 3 is opened There are ten radial grooves, each radial groove is fitted with a radial movable block 4 with teeth on its outer edge, and a spring 5 is installed between the bottom of each radial groove and the radial movable block 4 , all the conveying discs 3 on the same mandrel 1 are fixedly connected by a plurality of bolts and the end plates 2 installed at both ends; each radially movable block 4 has a limited long hole, and in this embodiment, the end plates 2 at both ends Ten stop rods 6 that pass through the stop slots of eighteen radially movable blocks 4 at a time are installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com