Dual reciprocating apparatus and saw blades for use therewith

A technology of reciprocating saws and saw blades, applied in the fields referred to here, can solve problems such as cutting unsuitable materials, increasing fatigue of positioning saws, and material damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

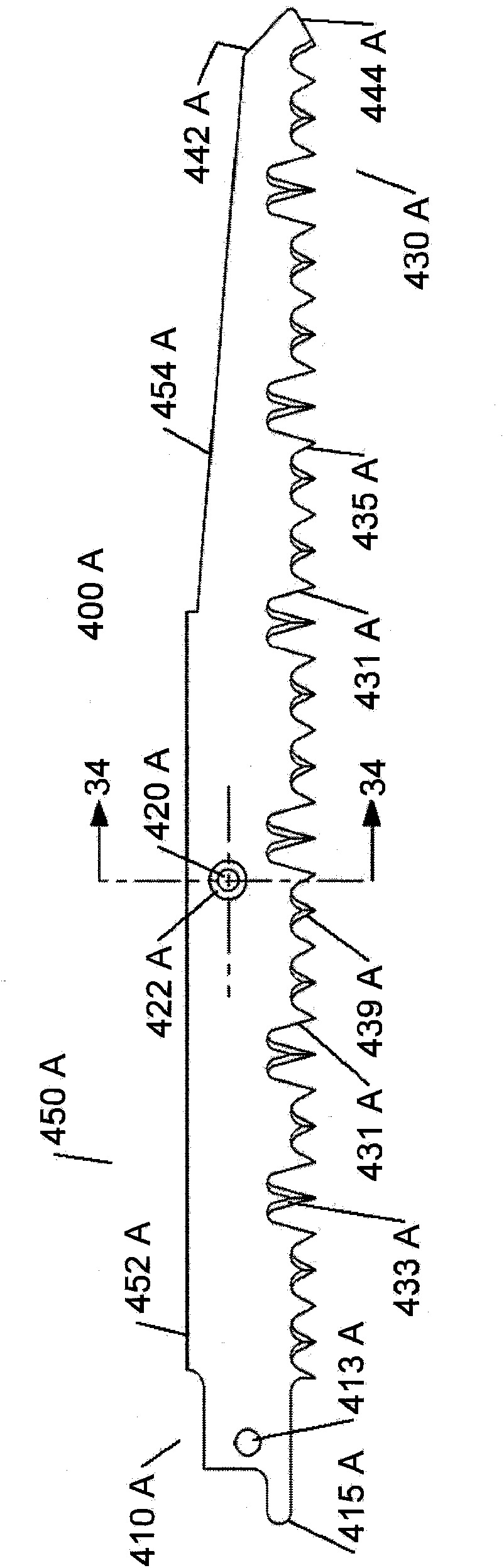

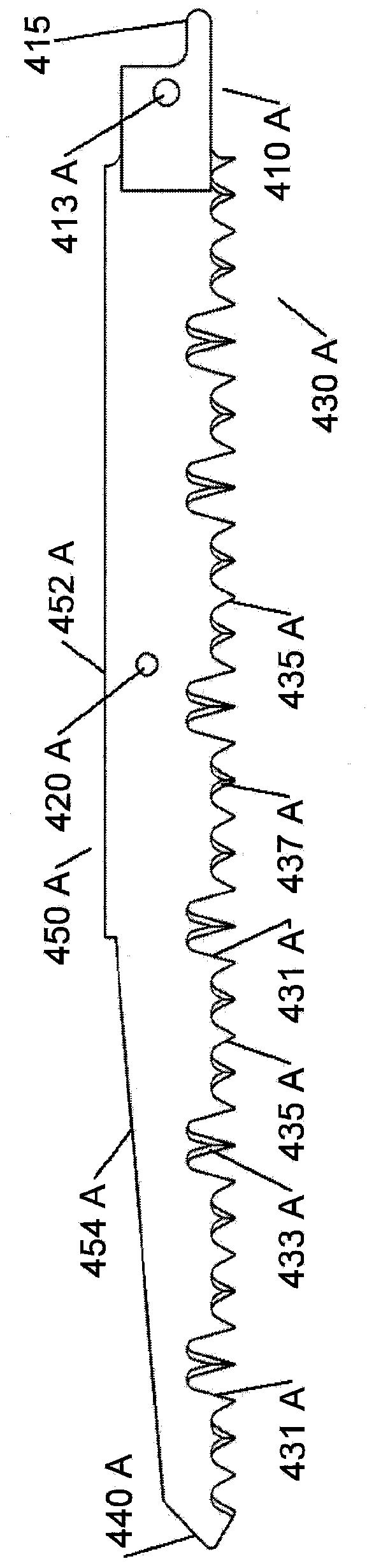

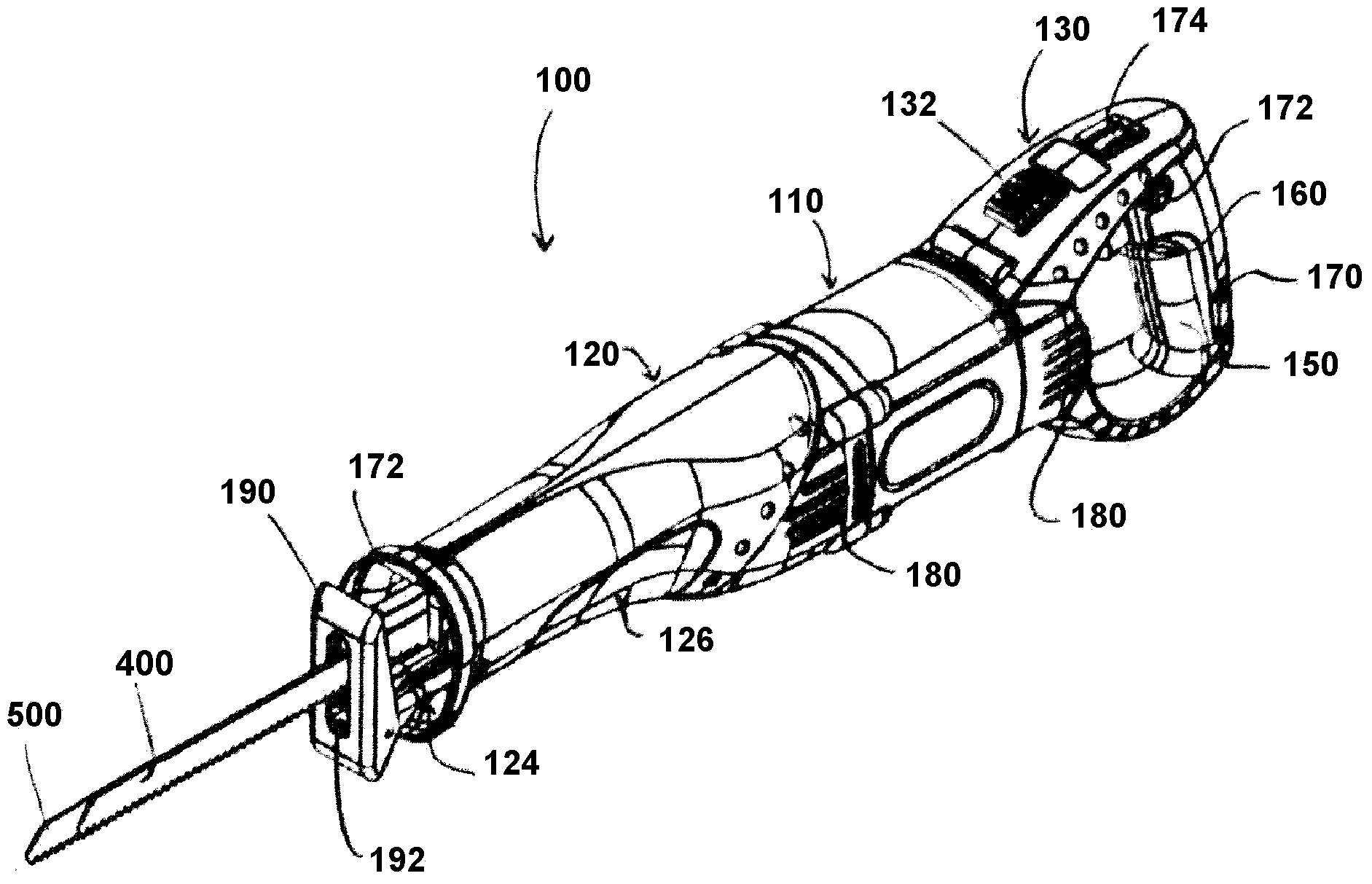

[0107] Referring now to the drawings, wherein each of the drawings is to illustrate a non-limiting embodiment of the present invention and not to limit the embodiment, Figure 1-43 A non-limiting embodiment of a reciprocating saw according to the invention is shown.

[0108] Figure 1-4 One non-limiting body 110 of a reciprocating saw 100 according to the present invention is shown. Figure 5-7 Another non-limiting body 110 of a reciprocating saw 100 according to the present invention is shown. The two bodies of the reciprocating saw are similar; however, Figure 5-7 The non-constrained body of the reciprocating saw shown in has a handle 130 that is pivotable and rotatable relative to the main body portion 120 of the reciprocating saw body. Figure 1-4 The handle 130 of the body of the reciprocating saw shown in FIG. The shape of the body of reciprocating saw 100 is non-limiting. It should be understood that the color of the reciprocating saw and the material used to make...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com