Engine demounting and mounting trailer

A technology for loading trucks and engines, applied in aircraft assembly, aircraft parts, ground devices, etc., can solve the problems of many interface docking points, difficult installation work, heavy structure weight, etc., to achieve the effect of free movement and no jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

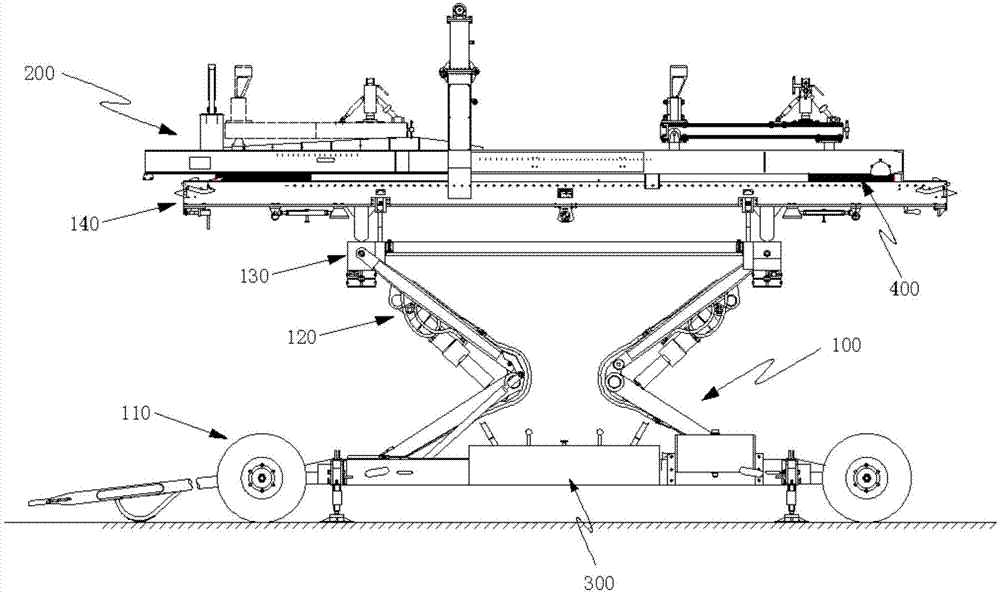

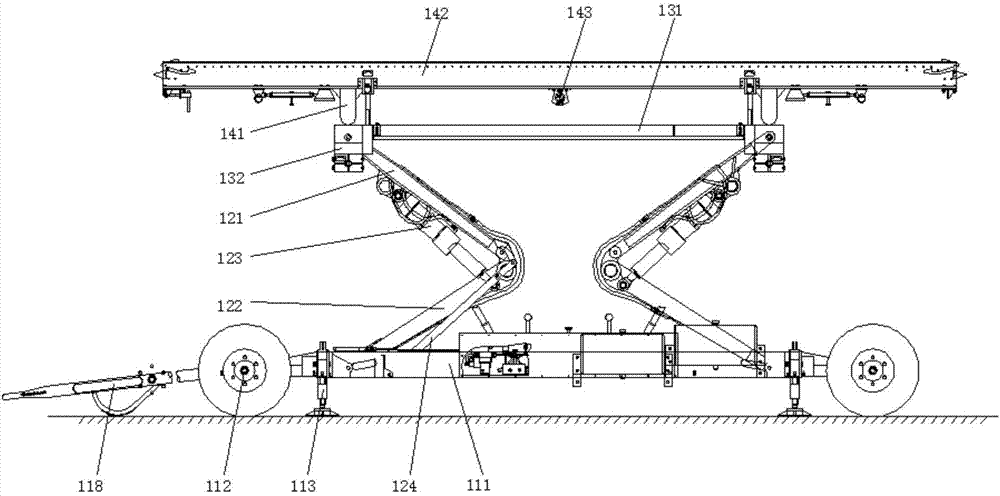

[0031] Such as figure 1 As shown, an engine disassembly and assembly trailer is composed of three parts: an installation vehicle (100), a disassembly platform (200) and a hydraulic system (300).

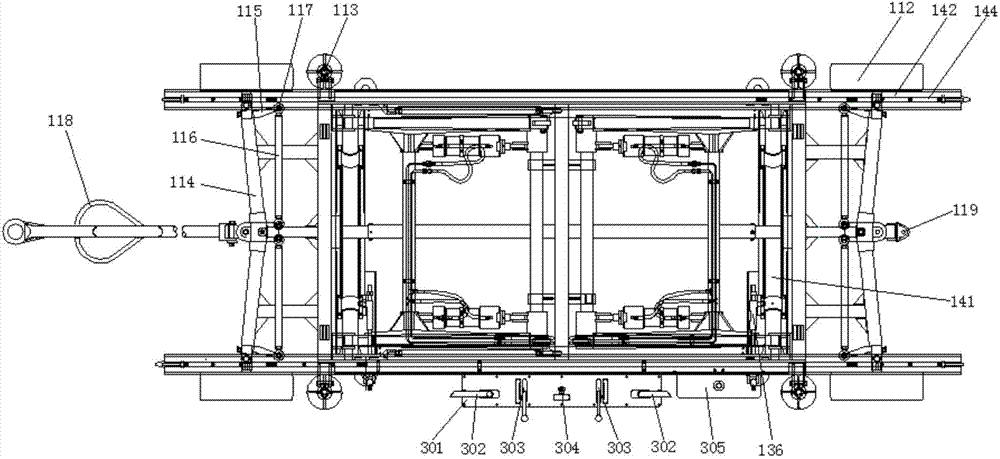

[0032] Such as Figure 2-4 As shown, the installation vehicle (100) is a lifting trailer, which is composed of a running mechanism (110), two sets of lifting mechanisms (120), a lateral movement mechanism (130) and a guide rail mechanism (140); the two ends of the running mechanism are respectively Two sets of lifting mechanisms are installed, the lifting mechanism drives the horizontal moving mechanism to rise or fall, and the horizontal moving mechanism drives the guide rail mechanism to move.

[0033] The running mechanism (110) is: the trailer chassis (111) is provided with traveling wheels (112) and bearing feet (113), the walking wheels (112) are solid rubber tires, and the four bearing feet are used to support the ground , to ensure that the trailer and the engine do not sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com