A permanent magnet synchronous motor rotor structure with bow-shaped permanent magnets

A technology of permanent magnet synchronous motor and rotor structure, applied in the direction of synchronous machine parts, etc., can solve the problem of poor sine of the air gap flux density waveform, achieve the effect of improving the air gap flux density waveform, expanding the scope of application, and improving the waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

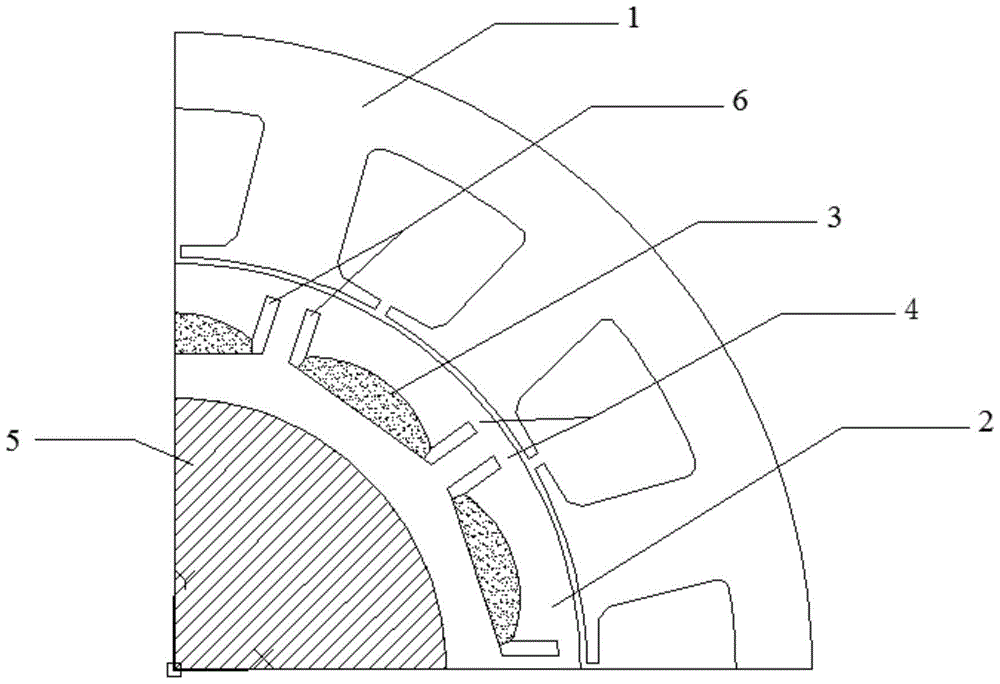

[0020] The invention provides a bow-shaped rotor structure of a permanent magnet synchronous motor, which has a rotor core, and each pole of the rotor core is provided with a permanent magnet and a magnetic isolation bridge; the permanent magnets in each pole are bow-shaped, and have an arc-shaped opening towards the center of the rotor core. Wherein, the permanent magnets in each pole are distributed symmetrically with respect to the radial centerline of the pole.

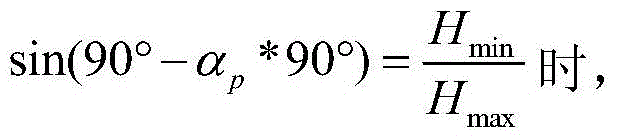

[0021] In this invention, the permanent magnets of each magnetic pole are arcuate and the arc-shaped side opens towards the center of the rotor core, and the maximum value of the thickness of the permanent magnet of a magnetic pole in the magnetization direction is H max Appears in the middle of the pole with a minimum thickness of H min Appearing at both ends of the magnetic pole, the pole arc coe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com