Let-off device of air jet loom

An air-jet loom and warp let-off technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of reduced service life, reduced overall performance of looms, large difference in warp tension, etc., to improve overall machine performance, The effect of solving the difficulty in adjusting the amount of loose warp and the loose warp time and the reasonable structure of the loom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

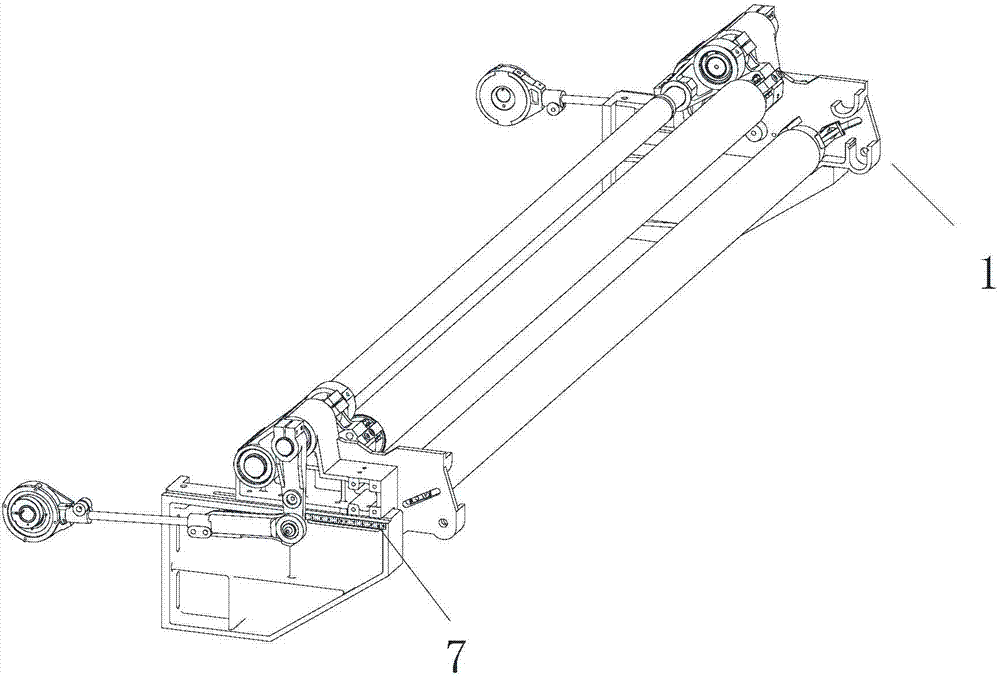

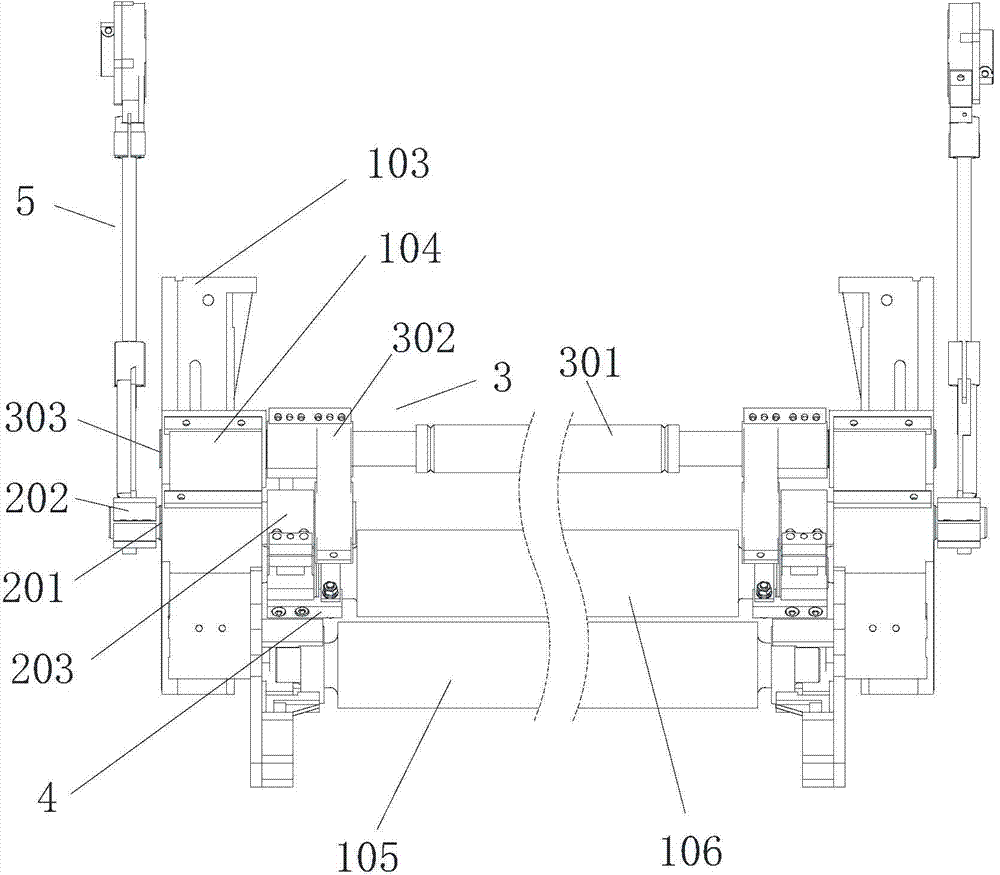

[0032] Such as Figure 1 to Figure 6 As shown, a let-off device for an air-jet loom includes a frame 1, and the frame 1 includes a left frame 101 and a right frame 102 with the same structure, and scale plates are arranged on the outside of the left and right frames 7. A tension roller 106 and a transition roller 105 are installed between the left and right frames. The left and right frames all include a lifting support 103 and a positioning seat 104 installed above the lifting support 103; the two positioning seats 104 are respectively Tension roller supporting mechanism 2 is installed, and each tension roller supporting mechanism 2 all comprises rocking shaft 201, and one end of each rocking shaft 201 is all equipped with rocking arm 202, and the other end is all equippe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com