Method for adjusting and controlling feeding mode of lime-dried municipal sludge cooperatively treated with cement kiln

A technology of drying sludge and co-processing, applied in cement production, clinker production, etc., can solve problems such as unstable performance of cement clinker, and achieve the effect of reducing energy consumption, improving production efficiency and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

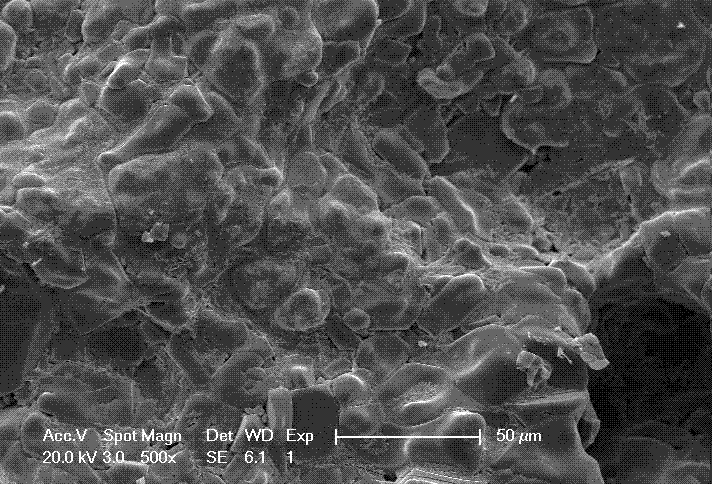

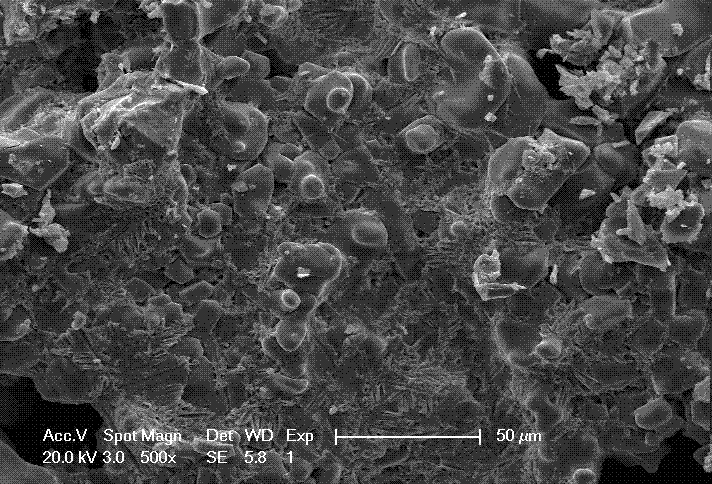

[0029] Combined with the actual process figure 1 As shown, there are two main feeding ports for the harmless disposal of lime sludge in the cement industry: one is feeding directly from the feeding port at the end of the raw meal mill; material.

[0030] Feed from the first feeding port

[0031]Lime-dried sludge is fed into the raw meal mill at the first feeding port and cement raw meal is mixed in different proportions, mixed evenly and finely ground in the vertical kiln to obtain cement raw meal, and then calcined at 1400°C for 60 minutes. Quenching, crushing, and ball milling to obtain cement clinker. Table 2 shows the test results of the burnability of cement raw meal prepared by mixing lime-dried sludge as one of the cement raw materials with traditional cement raw meal. It can be seen from Table 2 that replacing some of the traditional raw materials of cement with lime sludge can effectively improve the combustibility of cement raw meal. It can be inferred that un...

Embodiment 2

[0046] first feeding port

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com