Infrared device installation criterion validity method and installation criterion validity system

An equipment installation, infrared technology, applied in the field of testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

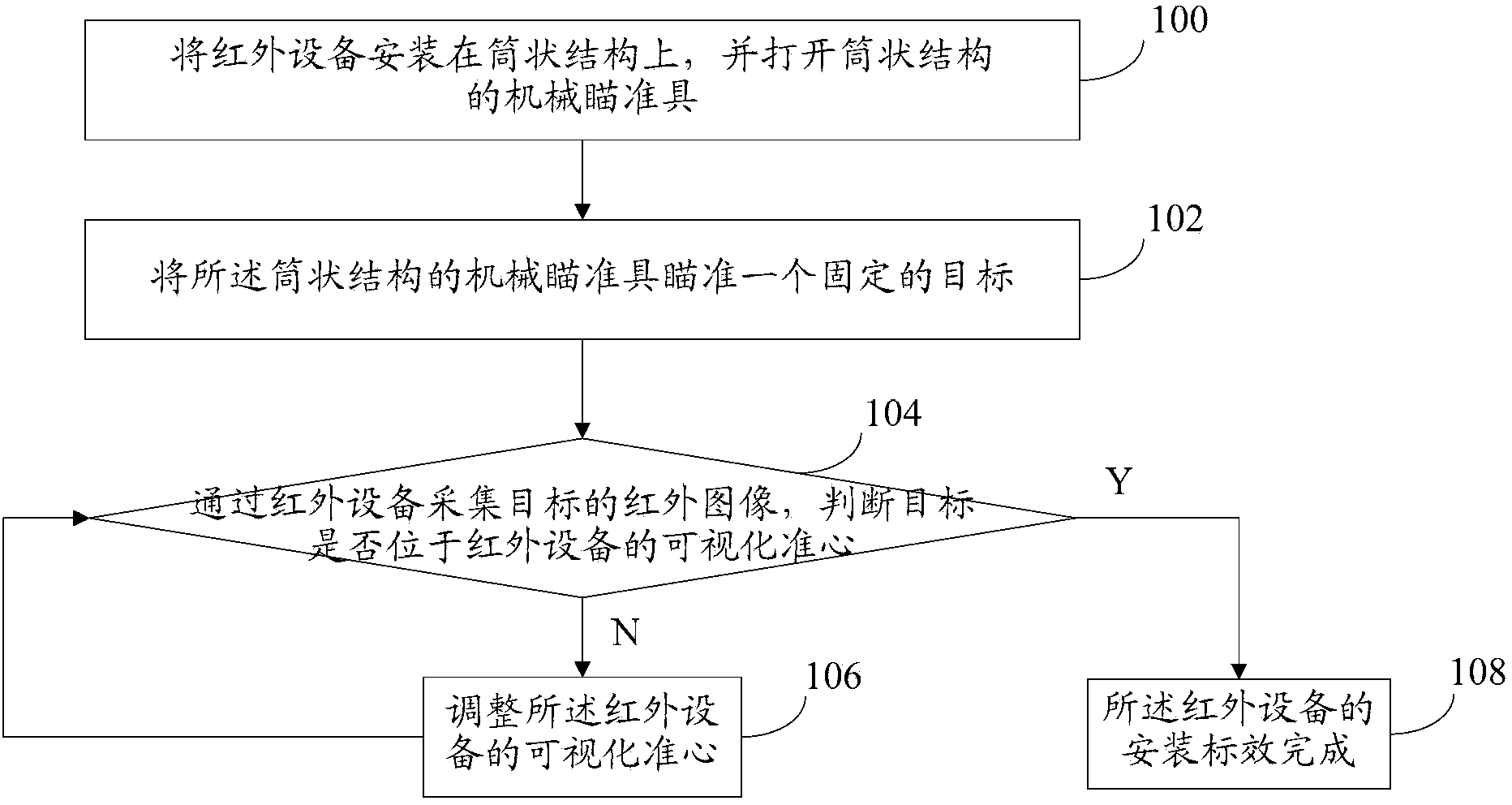

[0045] refer to figure 1 , which shows a flow chart of a method for installing an infrared device according to the present invention, and this embodiment may specifically include the following steps:

[0046] Step 100, installing the infrared device on the cylindrical part, and opening the mechanical sight of the cylindrical part;

[0047] After installing the infrared device on the cylindrical part and opening the mechanical sight of the cylindrical part, since the mechanical sight is installed on the cylindrical part itself, the shooter can use the infrared device and the mechanical sight on the cylindrical part to simultaneously Observe the target.

[0048] Step 102, aiming the mechanical sight of the cylindrical part at a fixed target;

[0049] In this embodiment, a distant fixed target can be selected, so that the cylindrical component can be stably aimed at the target through the mechanical sight. Choose a fixed target, iron sights can be easier to aim than moving tar...

Embodiment 2

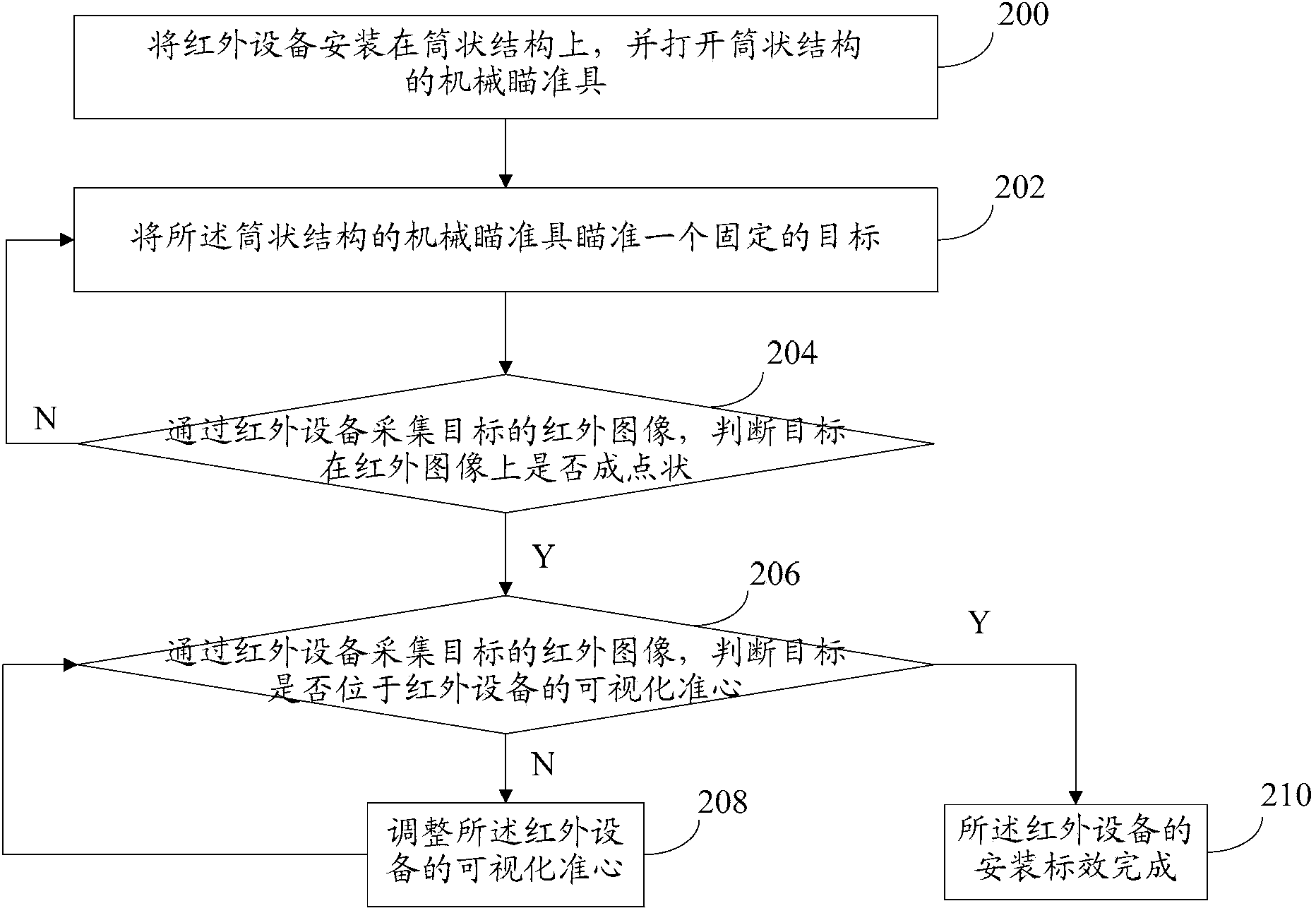

[0059] refer to figure 2 , which shows a flow chart of another method for installing an infrared device according to the present invention, and this embodiment may specifically include the following steps:

[0060] Step 200, installing the infrared device on the cylindrical part, and opening the mechanical sight of the cylindrical part;

[0061] After installing the infrared device on the cylindrical part and opening the mechanical sight of the cylindrical part, since the mechanical sight is installed on the cylindrical part itself, the shooter can use the infrared device and the mechanical sight on the cylindrical part to simultaneously Observe the target.

[0062] Step 202, aiming the mechanical sight of the cylindrical part at a fixed target;

[0063] In this embodiment, a distant fixed target can be selected, so that the cylindrical component can be stably aimed at the target through the mechanical sight. Choose a fixed target, iron sights can be easier to aim than mov...

Embodiment 3

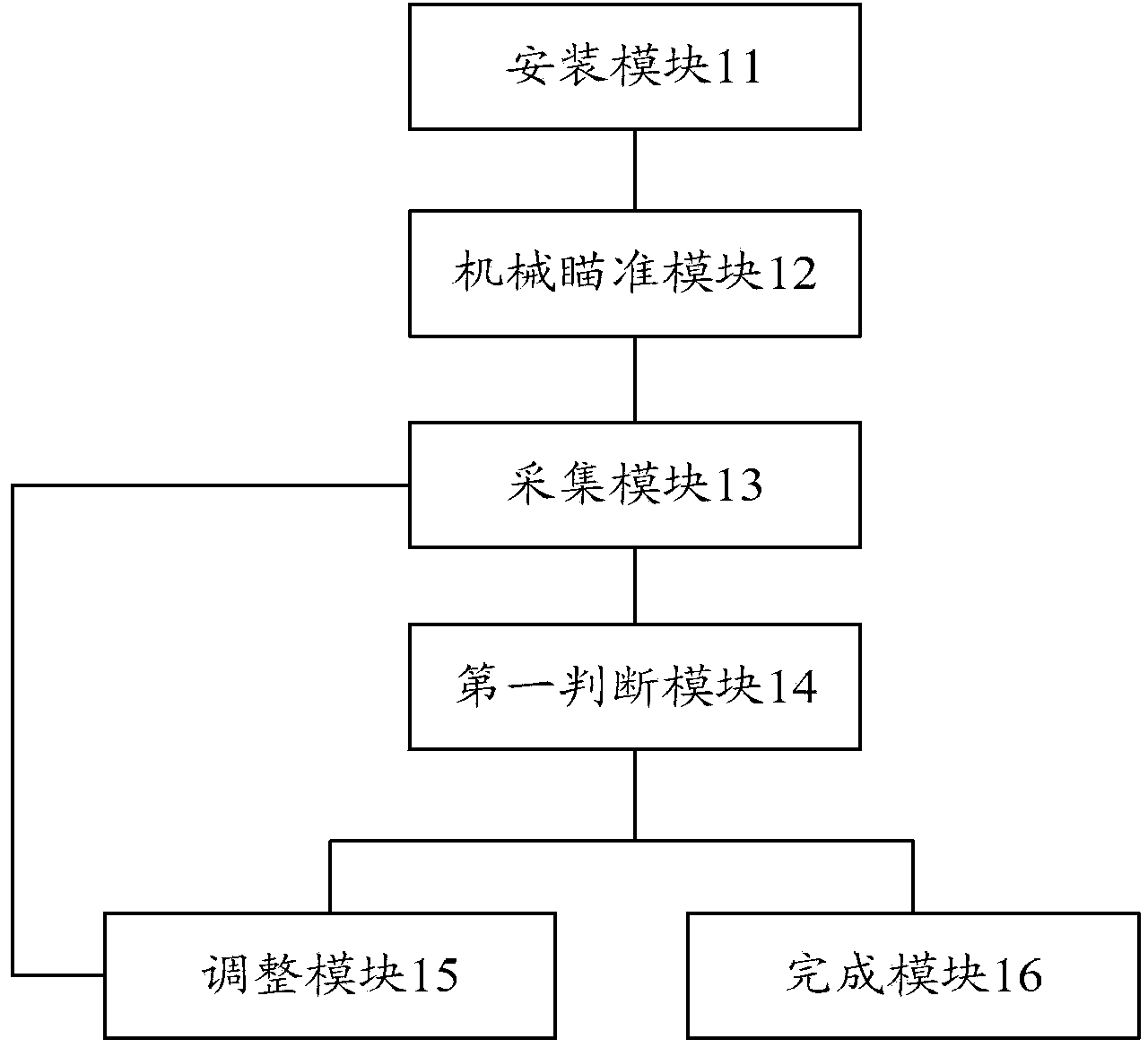

[0082] refer to image 3 , which shows a structural block diagram of an infrared device installation standard effect system according to the present invention, and this embodiment may specifically include the following modules:

[0083] The installation module 11 is used to install the infrared device on the cylindrical part and open the mechanical sight of the cylindrical part;

[0084] After the installation module 11 installs the infrared device on the cylindrical part and opens the mechanical sight of the cylindrical part, since the mechanical sight is installed on the cylindrical part itself, the shooter can pass through the infrared device and the mechanical sight on the cylindrical part. The sight simultaneously observes the target.

[0085] A mechanical aiming module 12, configured to aim the mechanical sight of the cylindrical part at a fixed target;

[0086] In this embodiment, the mechanical aiming module 12 can select a distant fixed target, so that the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com