A glue coating method and device

A gluing device and gluing technology, applied in the direction of the device and coating of liquid coating on the surface, can solve the problems of affecting the display effect of the LCD screen, uneven glue edges, and slow moving speed of the dispensing head. To achieve the effects of short gluing time, gluing production and adjustable gluing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

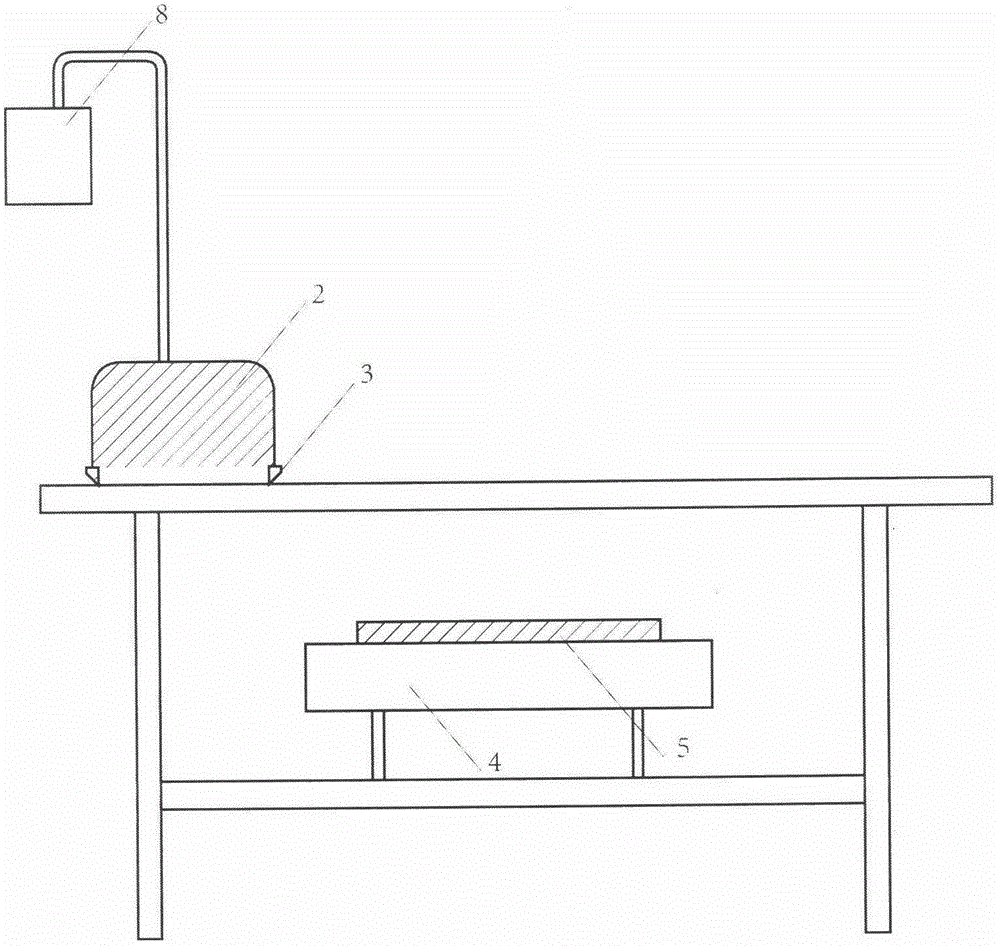

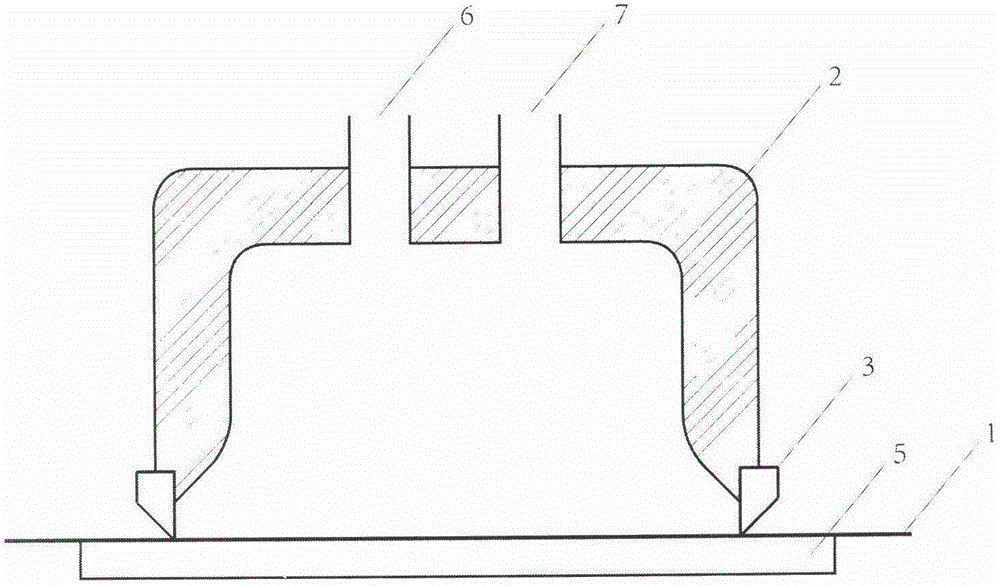

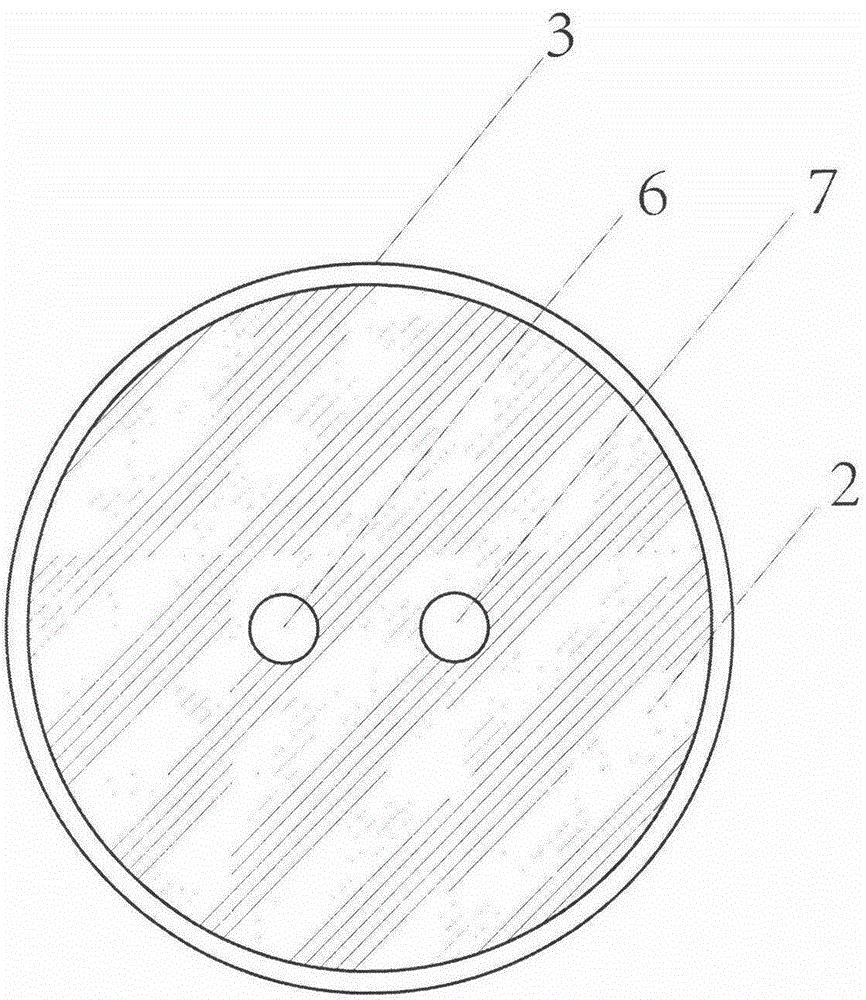

[0023] Example 1, such as figure 1 , 2 , 3 shown.

[0024] The present invention provides a kind of gluing method and device, and this method specifically comprises the following six steps:

[0025] Step 1, setting the glass substrate (4) to be glued on the preset liftable glass substrate platform (5).

[0026] In step 2, a steel sheet (1) is arranged above the glass substrate platform (5), and a glue-coated area is arranged on the steel sheet.

[0027] Step 3, setting a cup-shaped glue container (2) equipped with a metal annular knife edge (3) on the steel sheet (1), and forming a closed space. Subsequently, the airtight space is evacuated into a negative pressure through the air inlet (6).

[0028] In step 4, the liftable glass substrate platform (5) is raised and attached to the steel sheet (1).

[0029] Step 5, inject glue into the cup-shaped glue container (2) through the glue supply assembly (8) and the glue injection port (7).

[0030] Step 6, using a preset moti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com