System for twisting cables in wind turbine tower

A technology for wind turbines, cables, applied in the field of wind turbines, able to solve problems such as high risk, wear and bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

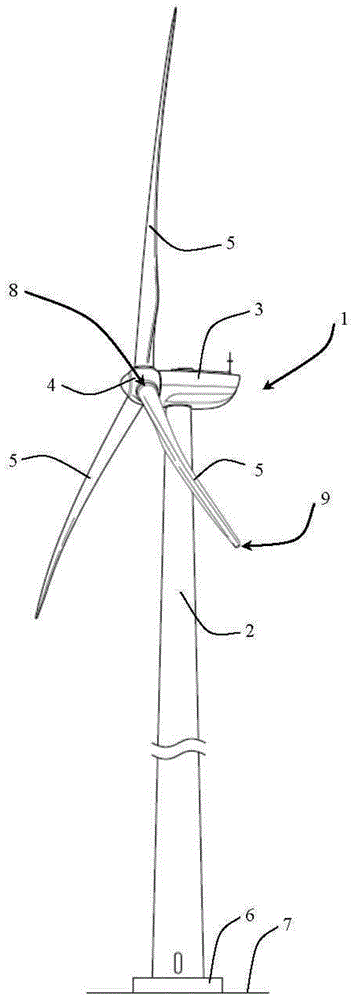

[0060] figure 1 An embodiment of a wind turbine 1 is shown comprising a wind turbine tower 2 and a nacelle 3 mounted on top of the wind turbine tower 2 . The wind turbine tower 2 may comprise one or more tower sections which are assembled together at the top. The rotor hub 4 is rotatably mounted to the nacelle 3 via a rotor shaft. One or more wind turbine blades 5 are mounted to the rotor hub 4 by a shaft extending outwards from the center of the rotor hub. Two or three wind turbine blades 5 may be mounted to the rotor hub 4, wherein the wind turbine blades 5 form a plane of rotation. The wind turbine tower 2 may be mounted on a foundation 6 which is raised above ground level 7 .

[0061] The wind turbine blade 5 may comprise a blade root 8 mounted to the rotor hub 4 . The wind turbine blade 5 may comprise a tip 9 arranged at the free end of the blade 5 . The wind turbine blade 5 has a streamlined profile along the length of the blade. The wind turbine blade 5 can be mad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com