A method and equipment for producing ultra-light water from light water

An ultra-light water and light water technology, applied in the field of nuclear applications, can solve the problems of large equipment investment, complex equipment, large investment, etc., and achieve the effect of ensuring safety and delaying the increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

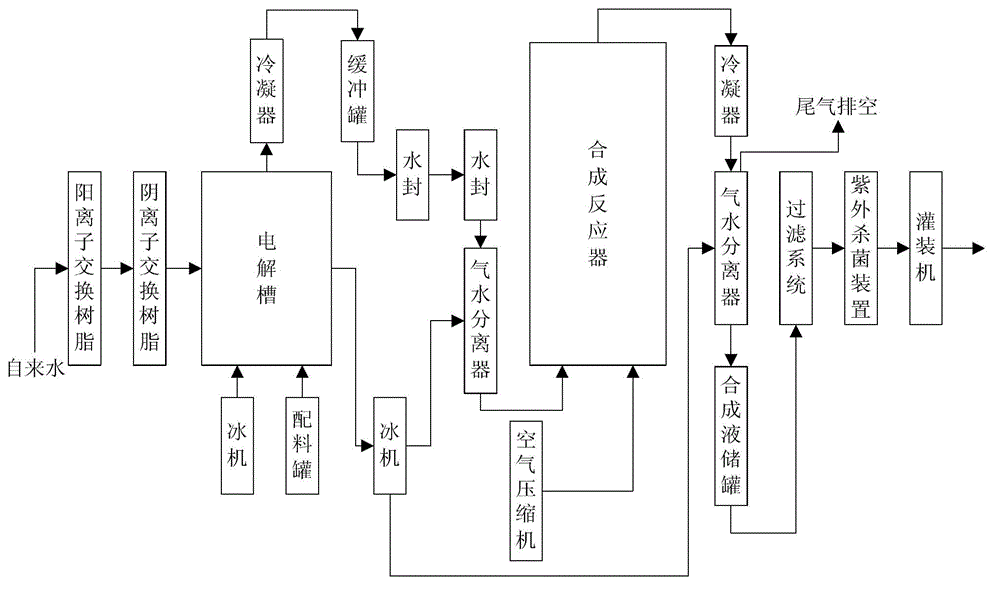

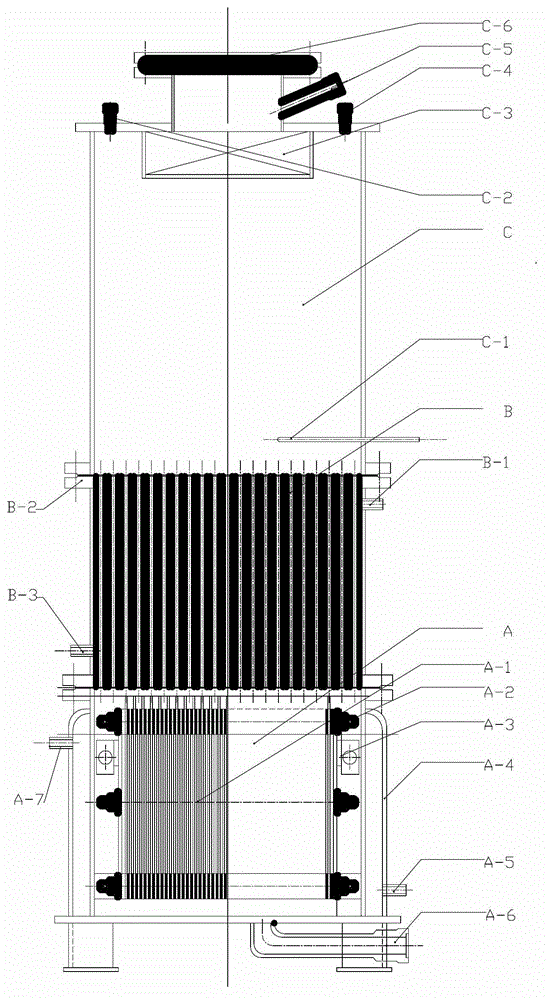

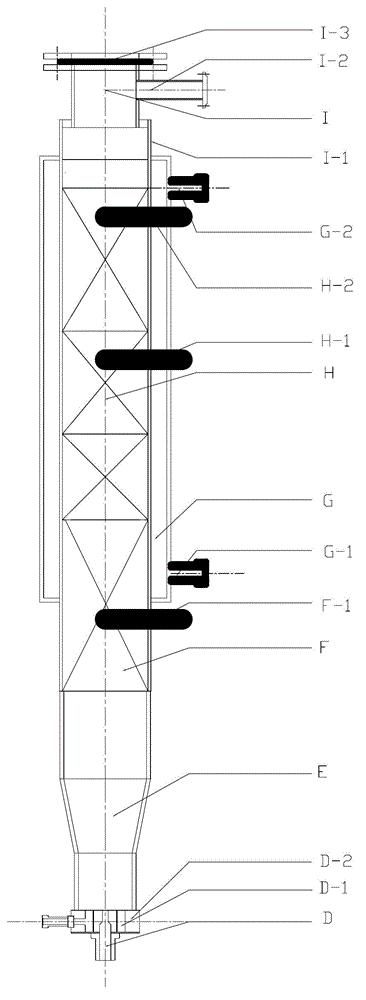

[0042] The main equipment for producing ultra-light water proposed by the present invention is a low-temperature non-diaphragm volume-reducing electrolyzer with a large protium-deuterium separation coefficient and operating at low temperature. The electrolyzer is composed of two parts: an electrolyzer box and a tube-and-tube condenser The diaphragmless electrolyzer is a box structure, with a length, width and height of 650×550×210mm, divided into upper, middle and lower sections, each of which is 700mm in height, and the sections are connected by square flanges. The lower part is the electrolytic tank body, the electrode plate in the tank is a plate-shaped structure, and there are 48 cathodes and anodes each. The pole segment plate is welded with a soft iron lead-out electrode with a cross-sectional area of 45×55mm, which is led out through the electrolyzer box by a copper rod with a diameter of 30mm, and is sealed by a pressure cap and a Teflon gasket. The cathode and anode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com