Method of Hot Stamping QR Code or Pattern Identification

A pattern identification and cursor technology, which is applied in the field of hot stamping two-dimensional codes or pattern identification, can solve the problems of high distance accuracy requirements between two-dimensional codes, failure to meet production requirements, and failure to meet requirements, so as to avoid cost risks and meet Large-scale hot stamping, using a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

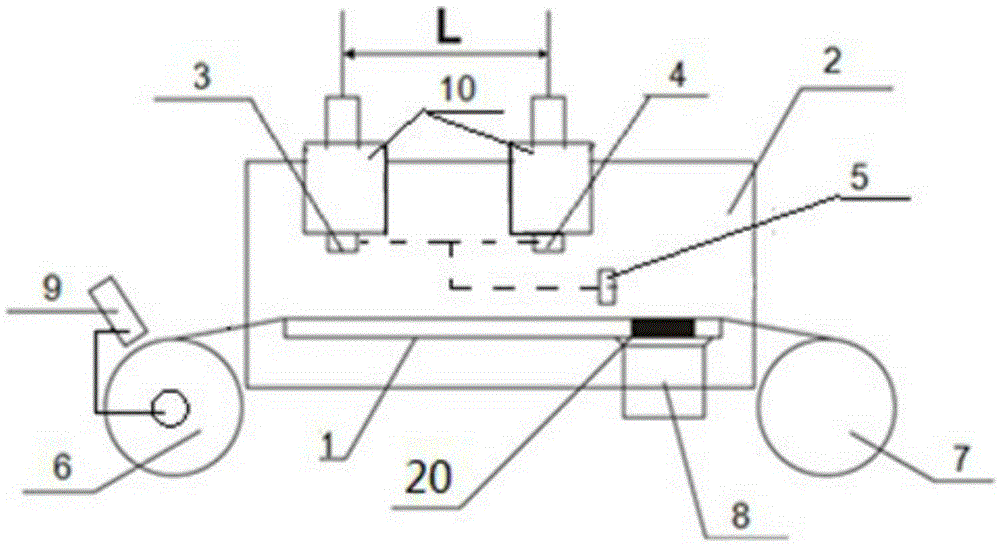

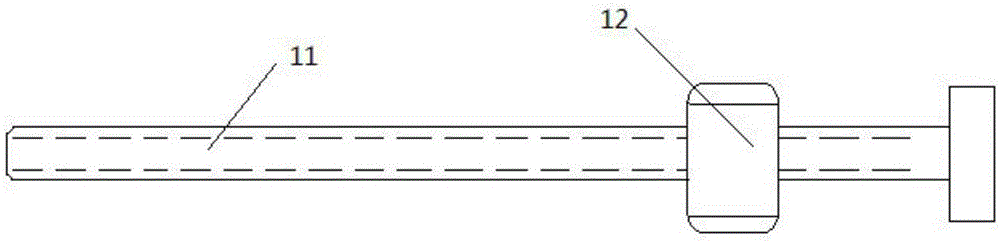

[0042] use figure 1 and figure 2 installation. Two Yikema F30 laser inkjet printers are used.

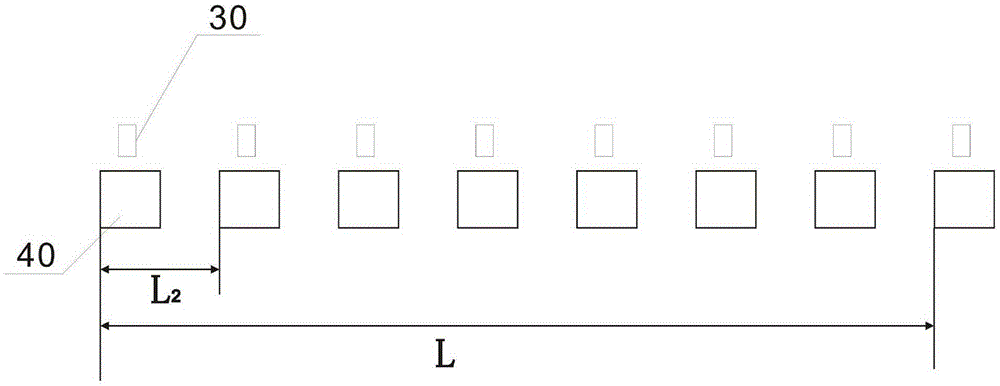

[0043] The laser is set as follows: output power 80%, laser repetition rate 80KHz, etching range 200×200mm, etching line speed 8000mm / s, empty pen speed 10000nn / s, filling line spacing 0.05mm. The jump stamping spacing L is 220.0mm. According to the hot stamping needs, set N=5, and calculate the spacing L between two adjacent patterns 2 The length is 20.0mm, and the stepping distance of the motor is set to 20.0mm±0.2mm.

[0044] The light output distance of the two lasers is 220.0mm.

[0045] During the etching process, the linear speed of the anodized aluminum foil is 5.0m / min, and the thickness of the anodized aluminum foil is 0.15mm±0.2mm. The uniformity of the end face of the anodized aluminum foil is set at ±0.2mm.

[0046] The anodized aluminum foil containing two-dimensional code or pattern information produced in this embodiment has no radial deviation, and the maximu...

Embodiment 2

[0048] In this embodiment, 8 Xiangsheng Laser D2000 fiber laser inkjet printers are used. Every two sets is a group, the light emitting distance is 210.0mm, and 4 groups of lasers are arranged at equal intervals horizontally.

[0049] The laser is set as follows: output power 50%, laser repetition rate 20KHz, etching range 200×200mm, etching line speed 3000mm / s, empty pen speed 10000nn / s, filling line spacing 0.5mm. The spacing L of jumping hot stamping is 210.0mm, and N=3 is set according to the needs of hot stamping, and the distance L between two adjacent patterns is calculated 2 The length is 30.0mm, and the stepping distance of the motor is set to 30.0mm±0.2mm.

[0050] During the etching process, the linear speed of the anodized aluminum foil is 3.0m / min, and the thickness of the anodized aluminum foil is 0.30mm±0.2mm. The uniformity of the end face of the anodized aluminum foil is set at ±0.2mm.

[0051] The anodized aluminum foil containing two-dimensional code or p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com