Welding protection tooling

A technology for protecting tooling and protective boxes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of heavy use, inflexibility, and the quality of welding is affected by external factors, etc., to achieve convenient and flexible use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with embodiment.

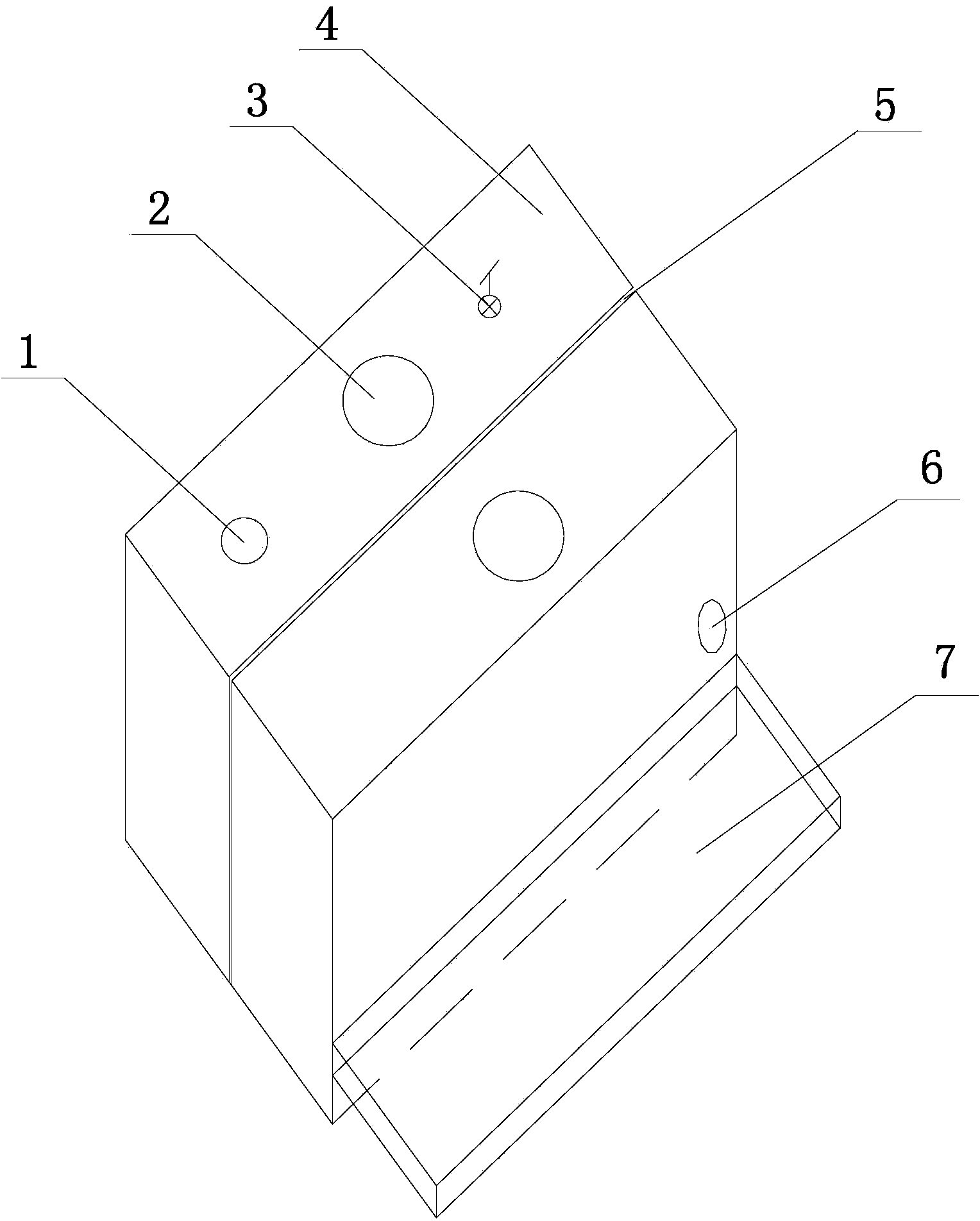

[0031] As shown in Figure 1, the welding protective tooling of the present invention is characterized in that it includes a protective box 4, which is a hexahedral cavity structure, and the hexahedron is composed of an upper side, a lower side, a left side, a right side, and a front side. and the rear side; an air inlet 6, which is arranged on one side of the protective box 4, and an air storage device is connected to the air inlet 6, and the air storage device passes through the air inlet 6 to The protective box 4 is filled with a mixed gas of carbon dioxide and oxygen; the exhaust port 1 is arranged on one side of the protective box 4; the operation port 2 is arranged on the upper side, and the operation port 2. Enabling welding tools and human arms to enter and exit the protection box 4 from the operating port 2; wherein, the upper side is a semi-transparent and anti-glare structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com