A kind of inoculation method of nodular cast iron

A technology of nodular cast iron and inoculation with flow, which is applied in the preparation of nodular cast iron alloys and the inoculation field of nodular cast iron, which can solve the problems of increased intergranular carbides, reduced mechanical properties of castings, and component segregation, and achieves the effect of reducing the content of residual magnesium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Inoculation in the molten iron ladle, the first inoculation in the molten iron ladle when it is released from the furnace is smelted in an intermediate frequency furnace at 1550°C, and the BaCaSi high-efficiency composite inoculant of the type J-3 is added at 0.45% of the total weight of the casting when it is released from the furnace, and placed in the molten iron ladle carry out the first pregnancy;

[0022] 2. Ladle inoculation, after step (1) the molten iron is allowed to stand to remove slag, then cool down to a pouring temperature of 1385°C, and add BaCaSi high-efficiency composite inoculant of model J-3 to 0.25% of the total weight of the casting during pouring. second pregnancy

[0023] 3. Flowing inoculation, when pouring, use 0.05% of the total weight of the casting to add SiZrSr special inoculant model P-1T for conventional instantaneous flow inoculation.

Embodiment 2

[0025] 1. Inoculation in the ladle, the first inoculation in the ladle when it is released from the furnace. The intermediate frequency furnace is smelted at 1550 ° C. When it is released from the furnace, 0.65% of the total weight of the casting is added to the BaCaSi high-efficiency composite inoculant of type J-3, and it is placed in the ladle. carry out the first pregnancy;

[0026] 2. Ladle inoculation, after step (1) the molten iron is allowed to stand still to remove slag, then cool down to a pouring temperature of 1390°C, and add BaCaSi high-efficiency composite inoculant of model J-3 to 0.35% of the total weight of the casting during pouring. second pregnancy

[0027] 3. Flowing inoculation, when pouring, use 0.1% of the total weight of the casting to add SiZrSr special inoculant model P-1T for conventional instantaneous flow inoculation.

Embodiment 3

[0029] 1. Inoculation in the molten iron ladle, the first inoculation in the molten iron ladle when it is released from the furnace is smelted in an intermediate frequency furnace at 1550°C, and the BaCaSi high-efficiency composite inoculant of the type J-3 is added at 0.55% of the total weight of the casting when it is released from the furnace, and it is placed in the molten iron ladle carry out the first pregnancy;

[0030] 2. Ladle inoculation, after step (1) the molten iron is allowed to stand to remove slag, then cool down to a pouring temperature of 1380°C, and add BaCaSi high-efficiency composite inoculant of type J-3 to 0.3% of the total weight of the casting during pouring. second pregnancy

[0031] 3. Flowing inoculation, when pouring, use 0.15% of the total weight of the casting to add SiZrSr special inoculant model P-1T for conventional instantaneous flow inoculation.

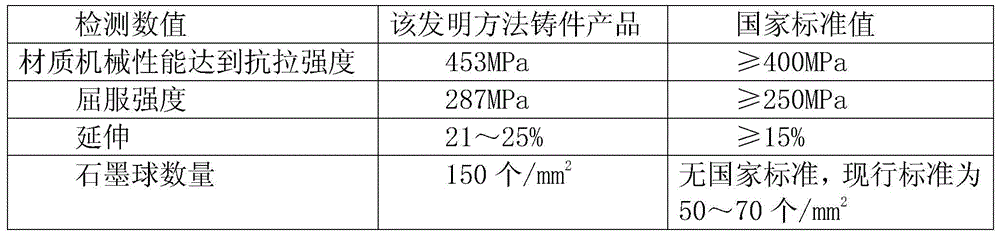

[0032] Tested by Shanghai Materials Research Institute as follows:

[0033]

[0034] It ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com